Culture method of Dunaliella and application of Dunaliella in biomass energy

A technology of biomass energy and breeding method, applied to the breeding method and its application in biomass energy, can solve the problems of rising grain and oil prices, ecological damage, etc., and achieve low cost, strong adaptability, and wide temperature adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

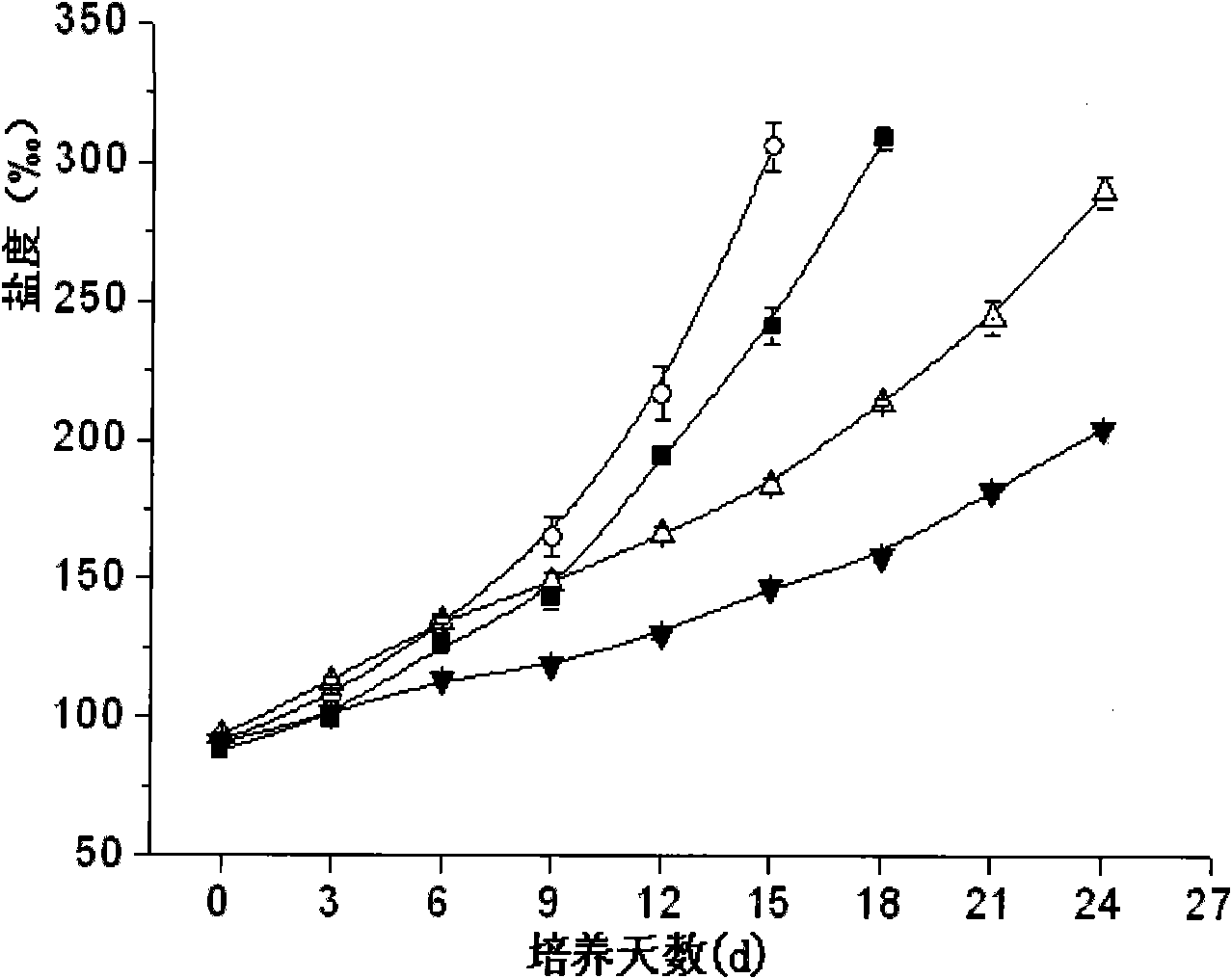

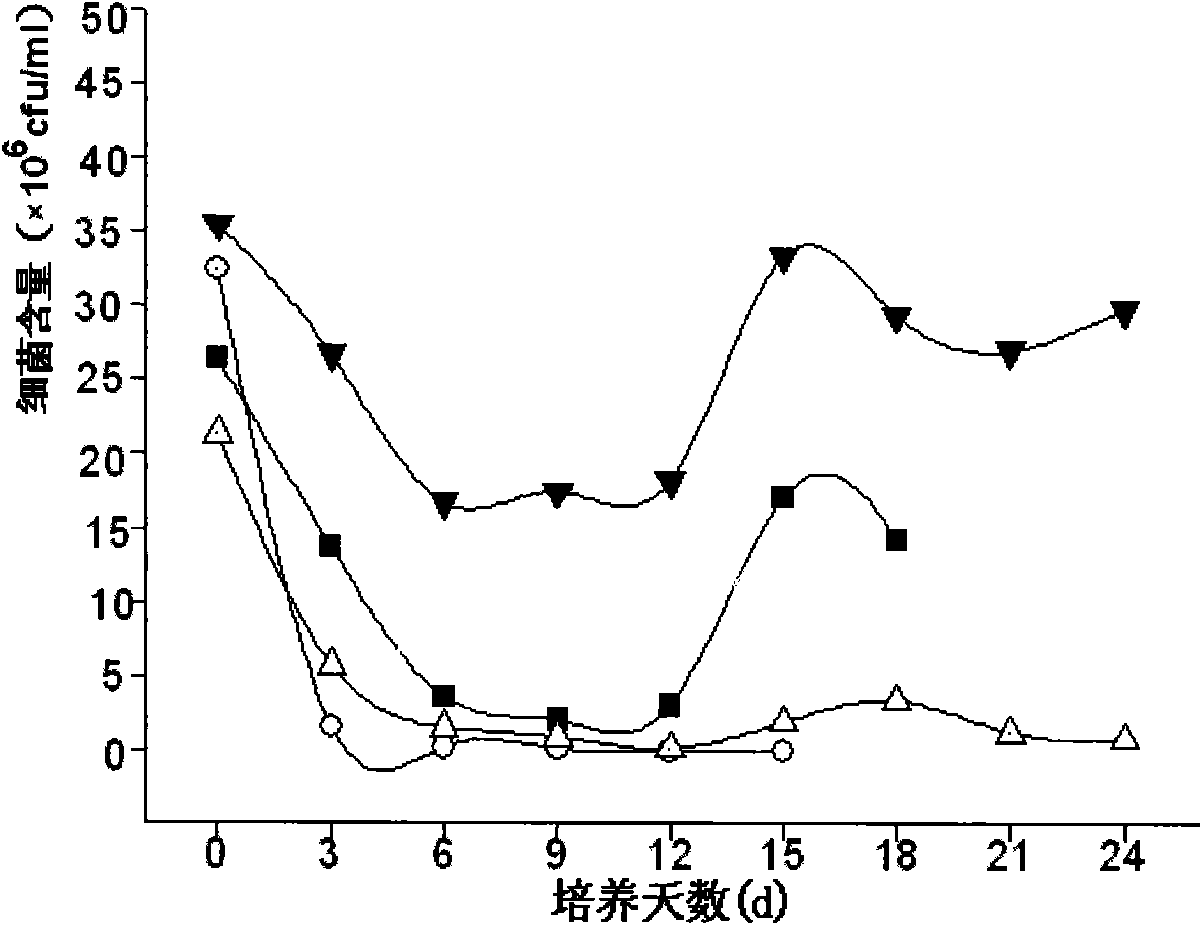

[0018] Dunaliella bardawil was cultivated with the concentrated seawater culture solution prepared above. During the breeding process, the annual change of the dry weight of algal cells of Pasteurella salina was between 0.3 and 2.0 g / L, and the biomass output was higher from January to April, and the output was lower in August and September. The algal cell production was lowest in April and July. In addition, the annual growth rate of the algal strain also varies significantly, and the average number of algal cells per milliliter of culture solution per day is (2.0~9.0)×10 5 Among them, the growth state of algae strains was the best in March, followed by November, and the high temperature from June to September caused the growth state of Salina strains to be poor.

[0019] The lipid content of algal cells of Pasteurella salina fluctuated between 5.0% and 25.2%. Among them, the lipid content of algal cells was the highest in April, followed by January, February, March, Novemb...

Embodiment 2

[0021] The high-temperature mutant strain of Salina was cultured with the concentrated seawater culture solution prepared above. During the breeding process, the annual change of the algal cell dry weight of the high temperature resistant mutant strain of Salina fluctuated between 0.3 and 2.2 g / L. Among them, the biomass output was the highest in March, followed by April and May, and the lowest in July. In addition, the annual growth rate of the algae strain changes significantly, and the average number of algae cells per milliliter of culture solution per day increases at (1.8~8.0)×10 5 Among them, the growth state of algal strains was the best in August, followed by March to July, and the growth of high temperature-resistant salina was slower in December, January and February, which was related to the lower temperature in winter.

[0022] The lipid content of algae cells of the high temperature resistant mutant strain of Salina salina fluctuated between 6.0% and 27.1%. Amo...

Embodiment 3

[0024] The high-fat mutant strains HL-1 and HL-2 of Salina were cultured with the concentrated seawater culture solution prepared above. The dry weight of algae cells in HL-1 and HL-2 was relatively close, fluctuating between 0.5-1.6g / L. The algal cell biomass production (dry weight) of HL-1 and HL-2 algal strains in April and October was higher than that in January and July (the lowest in July), and the high-fat haloalgae had higher yields in April, July and The dry weight of algal cells harvested in October was higher than that of the high temperature resistant mutant strain. It shows that the high-fat salina also has the characteristic of high temperature resistance. In addition, the growth rate of HL-1 and HL-2 algal cells varies between (2.0~15.5)×105 Individual / mL·d, all of them grew the fastest in April, and the slowest in January, and the growth speed of the high-fat salina in April, July and October was higher than that of the high-temperature resistant mutant strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com