Process for manufacturing and paving sidewalk rubber floor mat

A kind of sidewalk and rubber technology, applied in the directions of roads, roads, buildings, etc., can solve the problems of exhaust gas and waste water discharge, secondary environmental pollution, not easy to freeze, etc., and achieves good mute effect and anti-skid safety. The effect of high and reduced accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

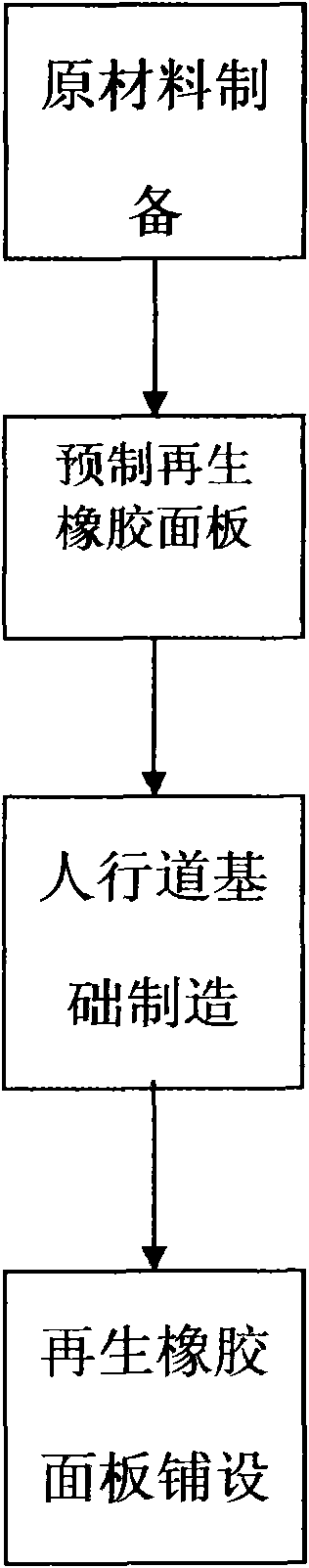

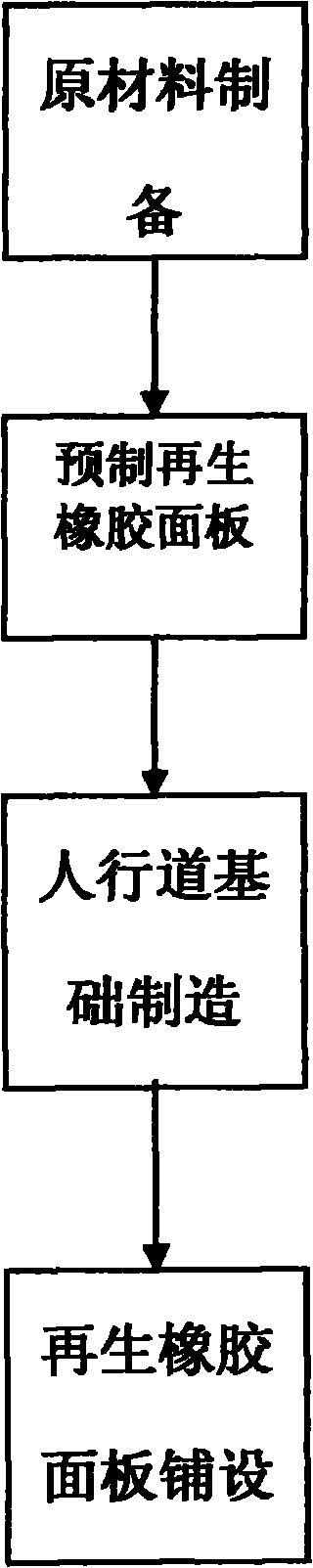

[0032] Refer to attached figure 1 , the production and paving process of rubber floor mats for sidewalks. The process includes four parts: raw material preparation, prefabricated recycled rubber panels, sidewalk foundation manufacturing, and rubber panel laying; the specific steps are as follows:

[0033] (1) Preparation of raw materials:

[0034] 1. Preparation of Colloidal Particles

[0035] The waste rubber is sorted, cleaned and cut into pieces that can be fed into the pulverizer, then crushed, screened through a 4mm hole screen, dedusted, iron and other metals are removed, measured, and packed for later use.

[0036] 2. Polyurethane glue preparation

[0037] Add polyether polyol to the reaction kettle by metering, heat and dehumidify under vacuum, keep a constant temperature, add polyisocyanate, stir for a specified amount of time, weigh and fill, and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com