Laser line light source system with uniform lighting

A technology of laser line light source and uniform lighting, which is applied to the components of lighting devices, lasers, electric light sources, etc., which can solve problems such as uneven exposure of images, and achieve the effect of solving light interference and eliminating clear shooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

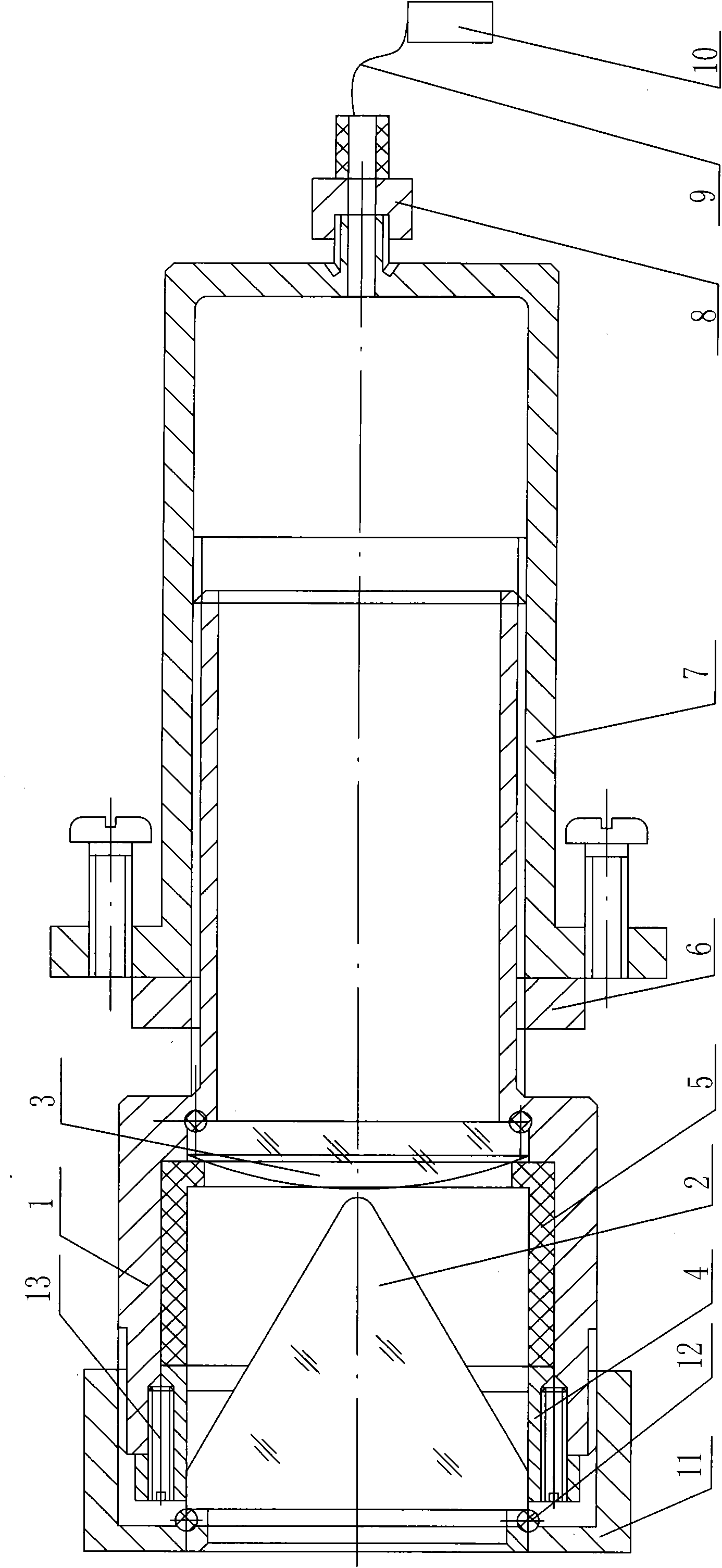

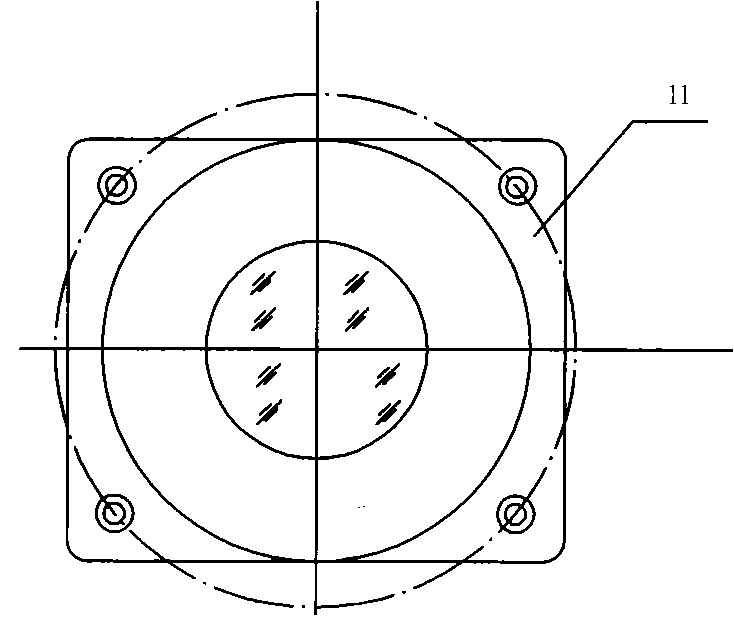

[0026] A uniformly illuminated laser line light source device, which consists of a stepped adjustable focus prism and a lens barrel 1. The position of the large diameter of the adjustable focus prism and lens barrel 1 is equipped with a prism 2 and a convex lens 3. The prism 2 is covered with a prism sheath 4, the prism sheath 4 is connected to the retaining ring 5, the adjustable focus prism, the small diameter position sleeve in the lens barrel 1 is connected to the adjustment nut 6 and the laser lamp body 7, One side of the laser lamp body 7 is connected to an optical fiber connector 8, and the optical fiber connector 8 is connected to a semiconductor laser 10 through an optical fiber 9, and the large-diameter end of the adjustable focus prism and lens barrel 1 is connected to a sealing glass cover 11.

[0027] The laser line light source device for uniform illumination, the other side of the laser lamp body 7 is connected with the adjusting nut 6, the adjustable focus prism...

Embodiment 2

[0030] Uniformly illuminated laser line light source system, the point light source output by the semiconductor laser is exported through direct connection or optical fiber transmission and then connected to the optical lens system. To the surface of the object to be photographed to achieve efficient and uniform illumination of the surface of the object to be photographed.

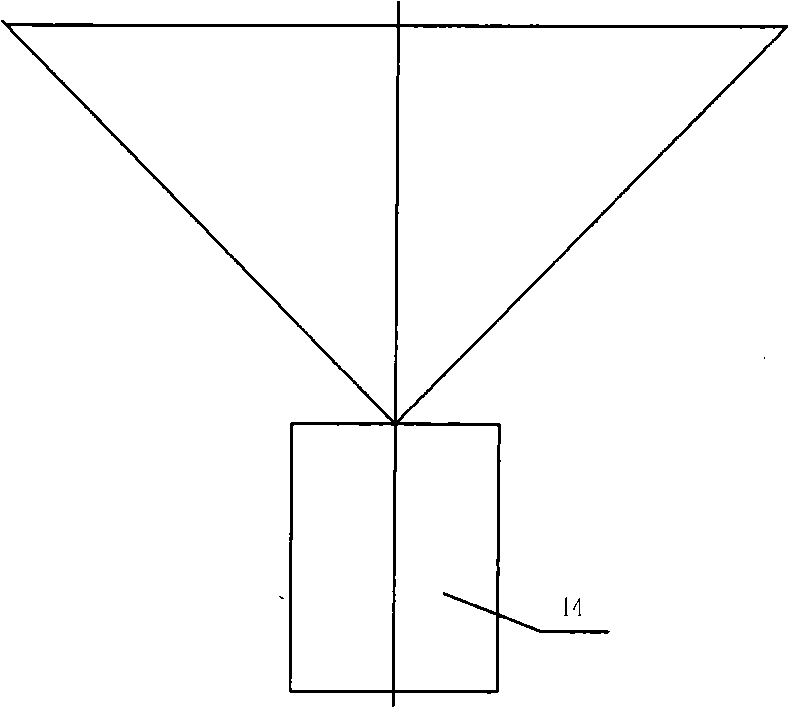

[0031] The monochromatic laser beam emitted by the semiconductor laser is transmitted through the optical fiber and then enters the optical lens system through the optical fiber connector. The focus of the beam is adjusted to a certain distance from the sealed glass cover. The laser beam passing through the convex lens is decomposed into a fan-shaped beam by the prism. The spatial distribution of the light source converted by the above optical system is an inverted trapezoidal fan-shaped light source.

[0032] The regular distribution of light intensity of fan-shaped light source in space is that the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com