Split-type reverse heat exchanger

A heat exchanger, split-flow technology, applied in the field of split-flow reverse heat exchangers, can solve the problems of wasting boiler rooms, environmental pollution, shortening the service life of boilers, etc., to reduce boiler damage, easy to use, and reduce fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

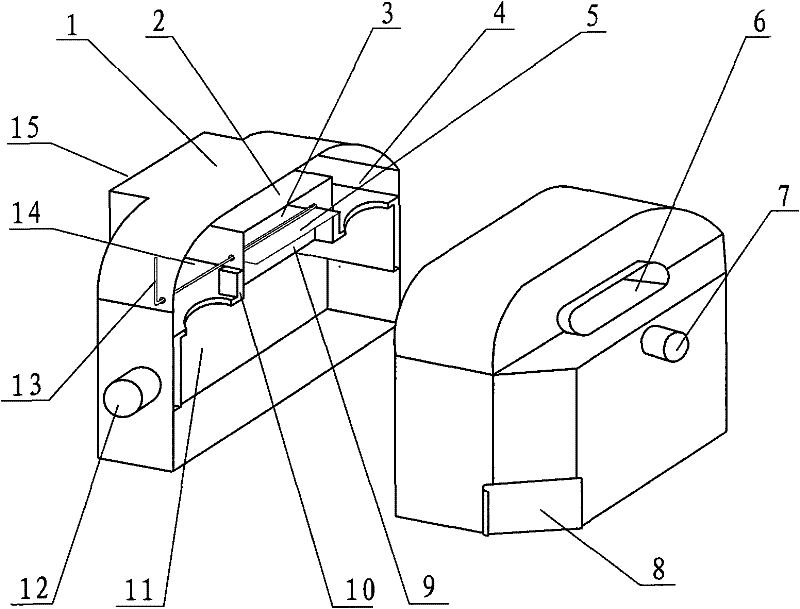

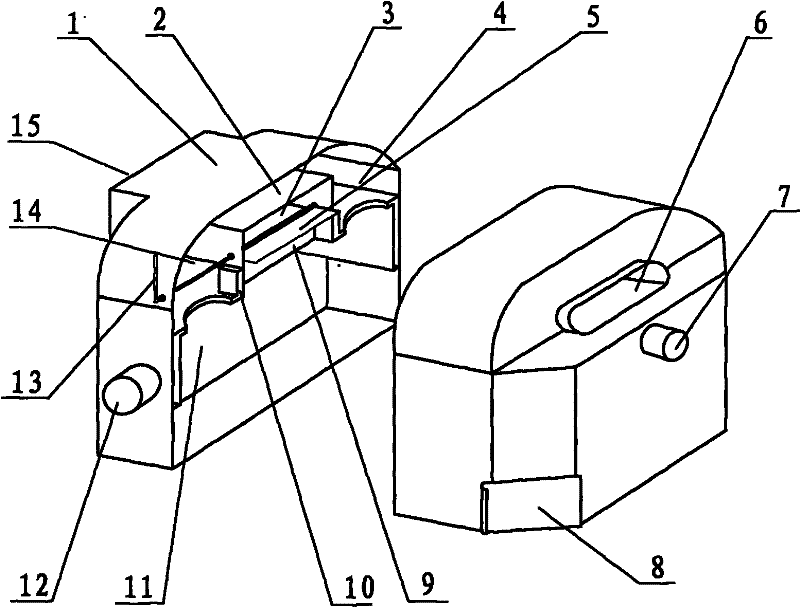

[0018] Such as figure 1 As shown, the main structure of the present invention includes a housing 1 with a smoke inlet 6 and a smoke outlet 15, and a three-way smoke pipe consisting of a straight-through smoke passage 3 and a retrograde smoke passage 9 is arranged on the upper side of the inside of the housing 1. The straight flue gas passage connects the flue gas inlet 6 and the flue gas outlet 15, the retrograde flue gas passage 9 is arranged below the combustion layer, and a controllable flue gas The flip baffle 5 of the flow direction is connected to the control handle 13; the water inlet 12 is arranged at the lower part of the side wall of the casing, and the water outlet 7 is arranged at the upper part of the side wall of the casing 1; 1 The body is provided with a stove-type circulating heat exchange jacket 10 which is connected to the water outlet 7 and the water inlet 12 and has a flue gas return port 4. The space of the shell 1 on the upper part of the circulating he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com