Resin composition for lamination, and laminate

A resin composition, a technology of polyolefin resin, applied in the field of laminates of lamination layers and resin compositions for lamination, can solve the problems of adhesion between lamination layers and substrates, reduction of tear strength, transparent surface It can reduce the tear strength and achieve the effect of excellent productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

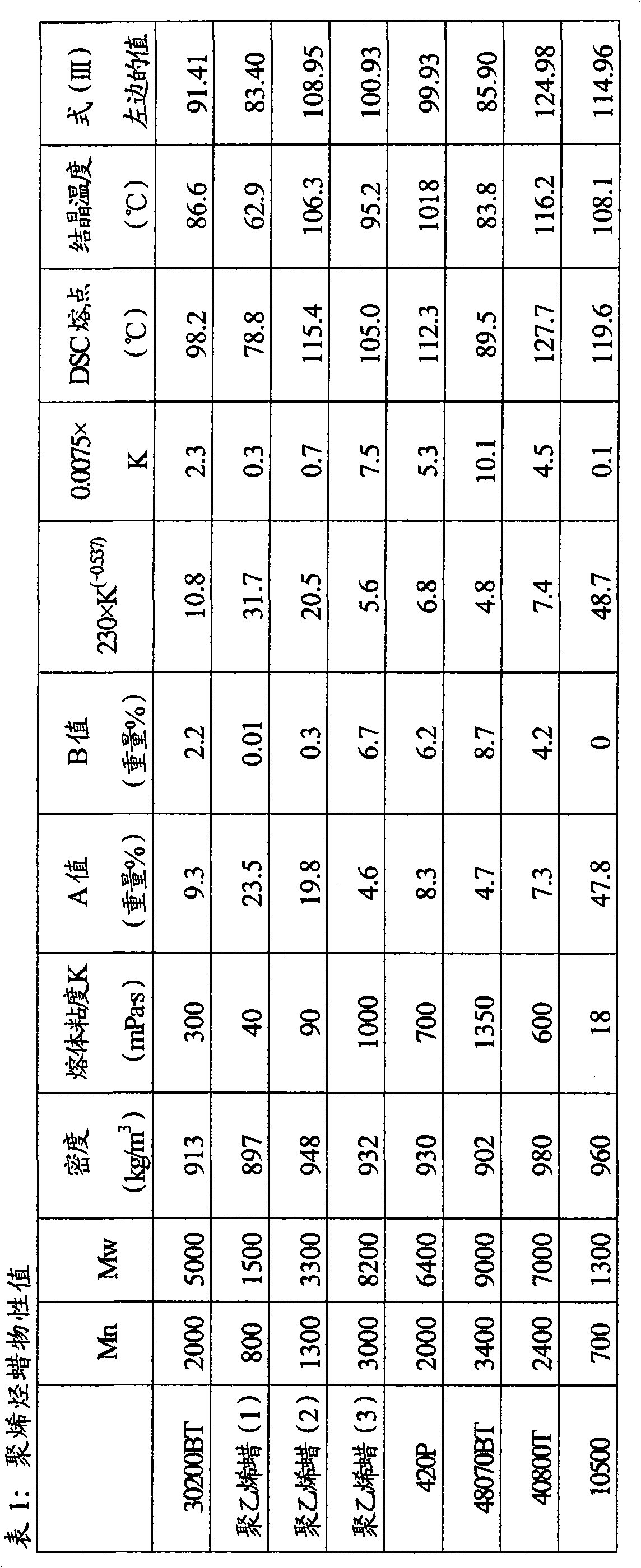

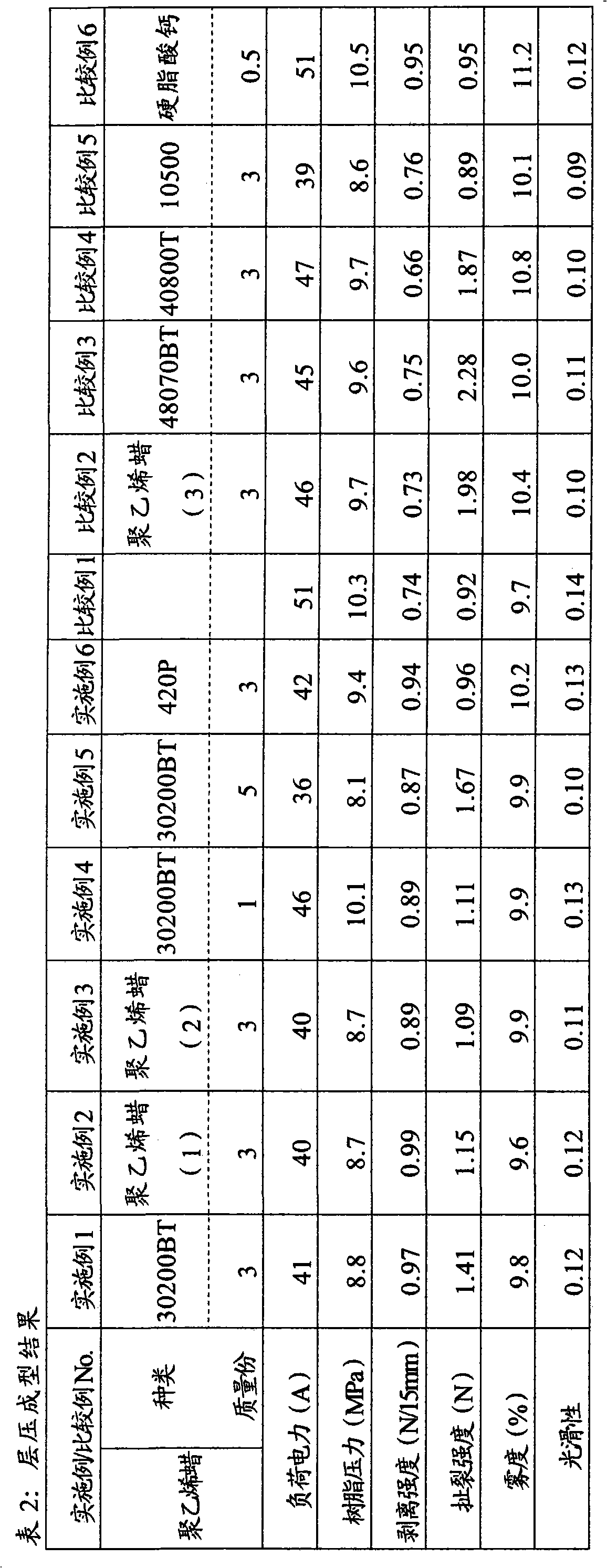

[0212] 100 parts by mass of the adjusted polyolefin resin and 3 parts by mass of polyethylene wax (EXCEREX 30200BT; manufactured by Mitsui Chemicals Co., Ltd.) were mixed and supplied to In the single-screw extruder, melt and knead at a resin temperature of 270°C, and extrude through a T-die under the conditions of a line speed of 70m / min, a thickness of 20μm, and a processing width of 620mm to form a biaxially stretched polypropylene film. On the formed substrate, a laminated film was obtained. The physical properties of this film were measured, and the results are shown in Table 2.

Embodiment 2

[0214] A laminated film was obtained in the same manner as in Example 1 except that the polyethylene wax was changed to polyethylene wax (1). The results are shown in Table 2.

Embodiment 3

[0216] A laminated film was obtained in the same manner as in Example 1 except that the polyethylene wax was changed to polyethylene wax (2). The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com