High-accuracy rotation locating control device of double-station plastic injecting and blowing hollow molding machine

A positioning control and double-station technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of high device cost, unintuitive setting of control parameters and control algorithm selection, increase of PLC execution time, etc. problem, to achieve the effect of high rotation positioning accuracy

Inactive Publication Date: 2010-11-10

柳州市精业机器有限公司 +1

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This type of positioning control device has the following deficiencies: 1. Because its human-machine interface is not designed specifically for the high-precision rotary positioning of double-station plastic injection blow molding machines, the blow molding molds for plastic injection blow molding machines Depending on the size of the rotating disk and the change of the radius of the rotating disk, the choice of setting control parameters and control algorithms is not intuitive, and the real-time dynamic position parameters of the rotation need to be transmitted to the man-machine interface of the control system through PLC programming to be displayed; 2. In order to achieve high precision The positioning control needs to use an electronic ruler with 12-bit data and configure an A / D conversion module. It is necessary to compile a PLC execution program with more than 1200 steps, which increases the execution time of the PLC, which in turn leads to an increase in the execution cycle of the PLC user program, which affects the double-station plastic. Fast operation of injection blow molding machine; 3. Its control circuit mode cannot communicate with the upper computer, and cannot observe and analyze its dynamic operating state curve in detail; 4. The device cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

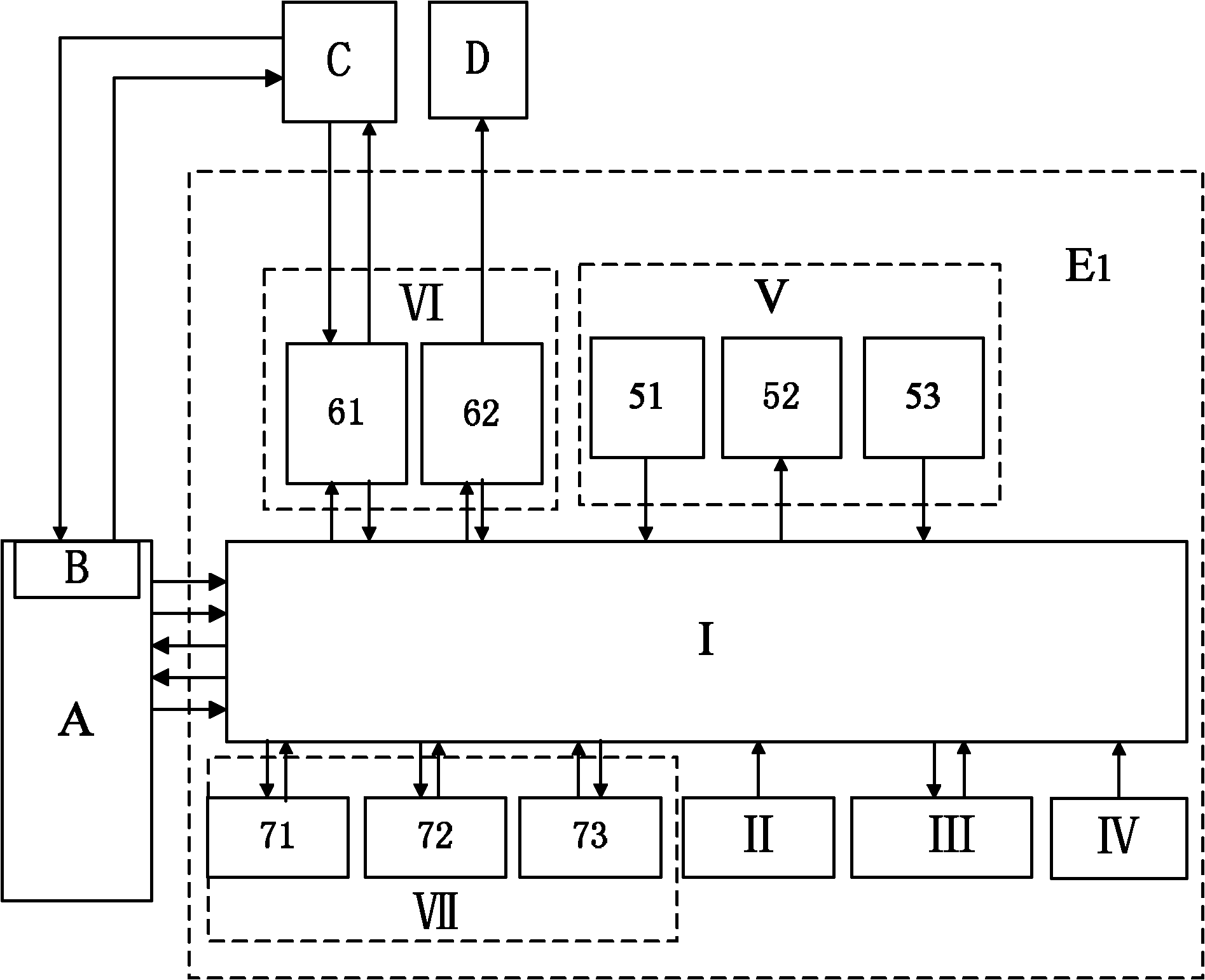

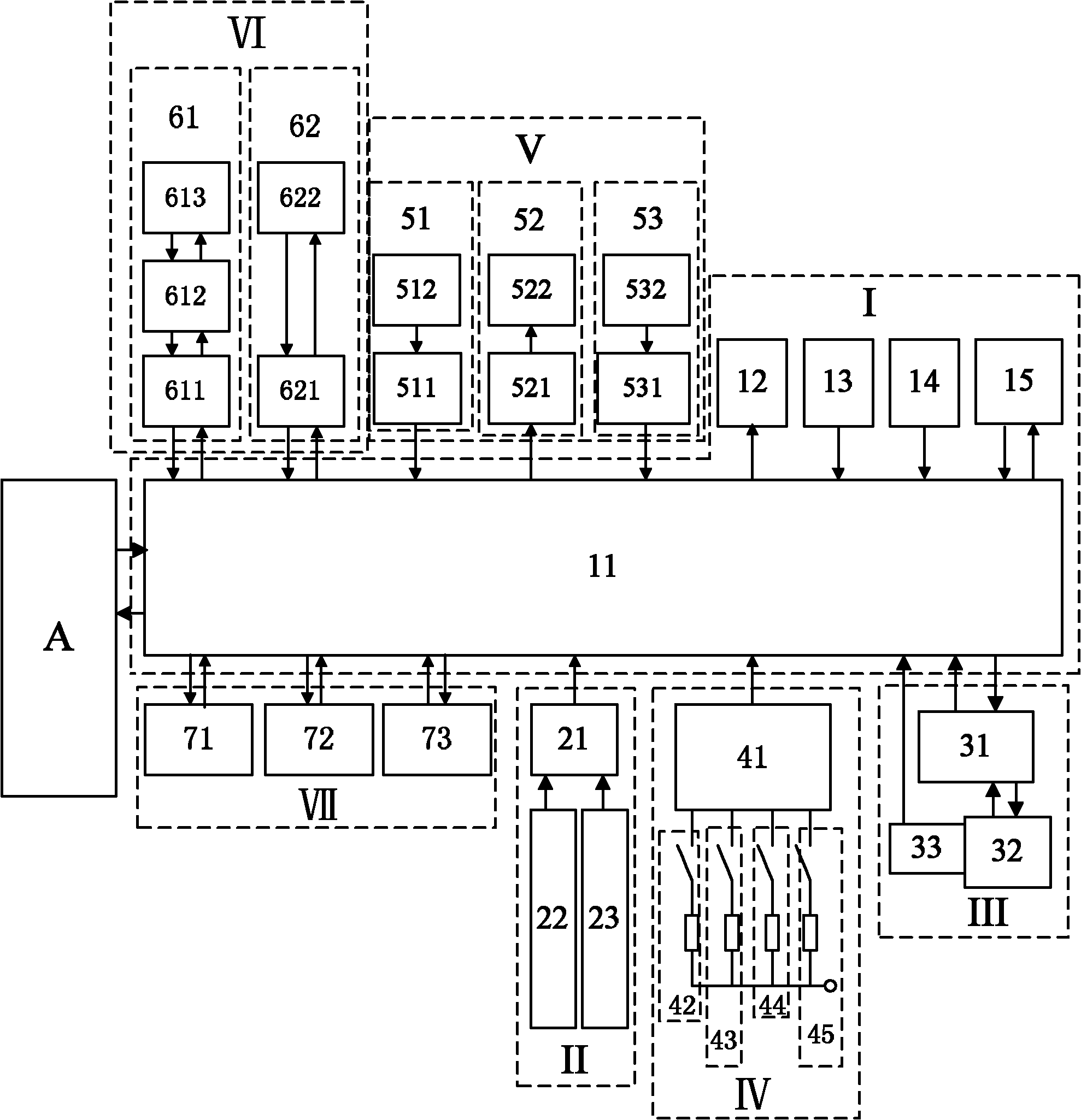

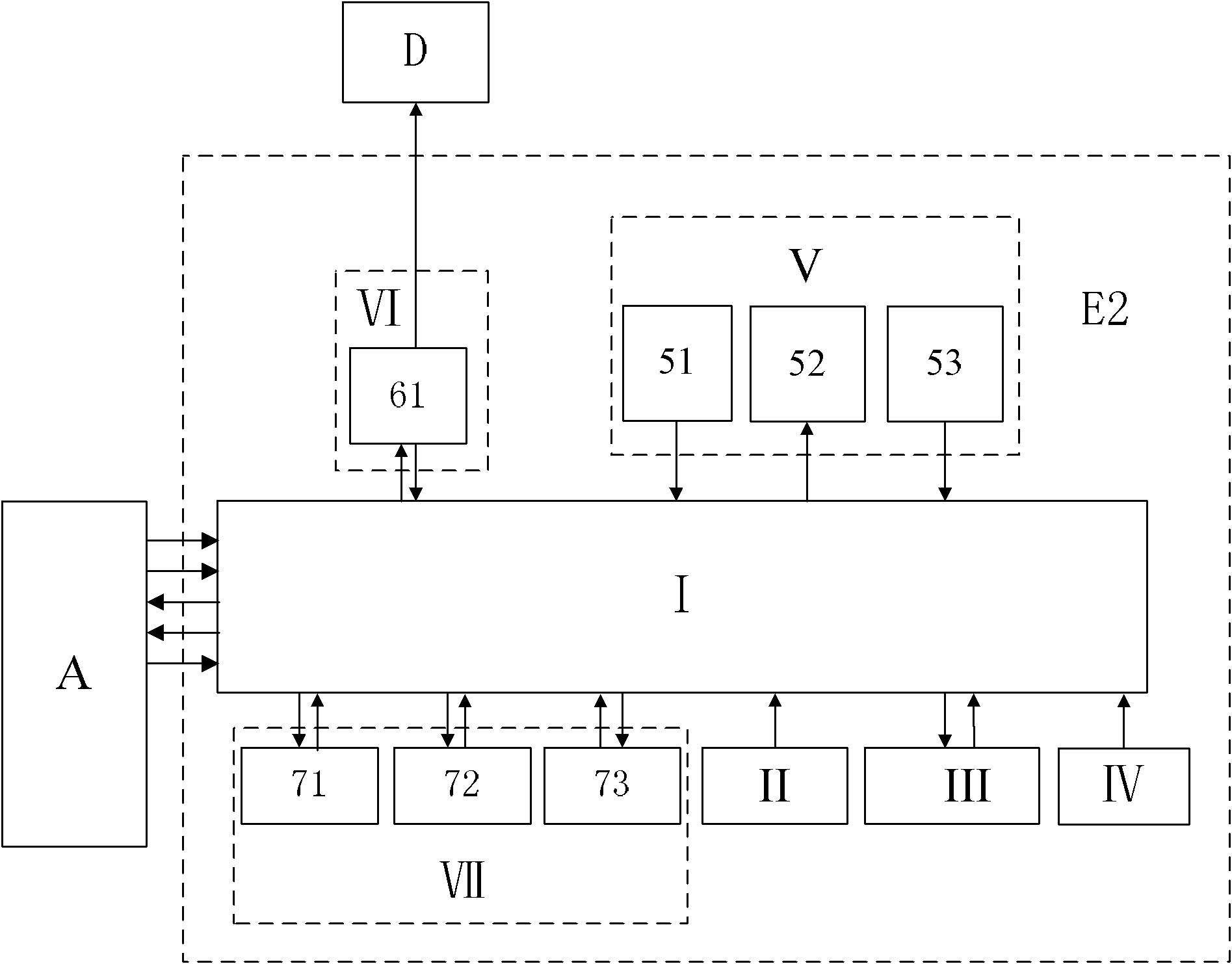

The invention relates to a high-accuracy rotation locating control device of a double-station plastic injecting and blowing hollow molding machine, which comprises a master control module as well as an electronic ruler data acquisition module, a servo motor drive and encoder module, a sensing limit switch module, a human-computer interface module, a communication interface module and a storage module that are respectively connected with the master control module, wherein the master control module comprises an embedded ARM microprocessor, an alarm output module, a power supply module, a reset circuit and a JTAG debugging interface circuit; and the embedded ARM microprocessor of the master control module is connected with an input / output interface of a PLC, is used for receiving starting rotation direction information and resetting information which are sent out by a PLC host machine, and transmitting clockwise and counterclockwise rotation located information into the PLC host machine. The device is provided with a special human-computer interface device, thus realizing high-accuracy rotation location, and not influencing the user program execution period; the device has multiple communication ways so as to realize interaction with a human-computer interface of a control system and the communication with an upper computer; and the device has high cost performance.

Description

technical field [0001] The invention relates to a programmable logic controller (PLC) servo motor control device, in particular to a high-precision rotary positioning control device for a double-station plastic injection blow molding machine with an embedded ARM microprocessor as the control core. Background technique The double station of the double station plastic injection blow molding machine means that there are 2 rows of injection blow molding core modules, one row is in the working state of injection molding, and the other row is in the working state of blow molding, and each completes injection molding, After blow molding, the 2-row injection blow molding core module needs to be rotated 180°. The rotation process is a relatively independent process of the plastic injection blow molding machine, so it requires high speed and can control its clockwise and counterclockwise rotation, clockwise and counterclockwise rotation. The stop position of the counterclockwise rota...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C49/78B29C49/06G05B19/05

Inventor 文澜蔡启仲周常凯李晖周苏茂罗功琨

Owner 柳州市精业机器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com