Production method of hot stamping foil

A production method, anodized aluminum technology, applied in temperature recording method, coating, etc., can solve the problems of water-based anodized aluminum and alcohol-soluble tipping paper hot stamping, low temperature of anodized aluminum hot stamping, poor post-press adhesion, etc. , to achieve the effect of bright color, not easy to fall off, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

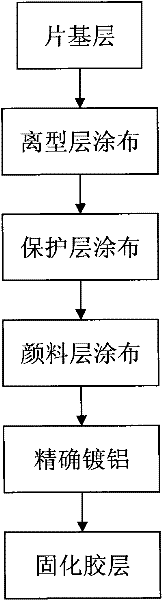

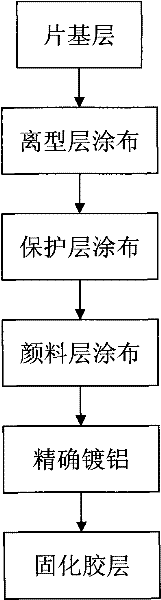

[0025] As shown in the accompanying drawings: a production method of bronzing anodized aluminum, comprising the following steps:

[0026] 7) choose the PET polyester original film as the base layer;

[0027] 8) Use a water-based release material to coat and dry the base layer to form a release layer;

[0028] 9) Use water-based varnish on the release layer to coat and dry to form a protective layer;

[0029] 10) Use water-based blending pigments on the protective layer to coat and dry to form a pigment layer;

[0030] 11) Vacuum aluminum plating on the pigment layer, that is, the film coated with the color layer, etc., is placed in the vacuum chamber of the continuous aluminum coating machine, and the aluminum wire is melted and continuously evaporated to the pigment of the film by resistance heating under a certain vacuum degree On the layer, an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com