Hot mending material for spray gun

A technology of thermal repair and spray gun, which is applied in the field of iron and steel smelting, can solve the problems of poor thermal stability, peeling, short service life, etc., and achieve the effects of good thermal stability, enhanced plasticity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

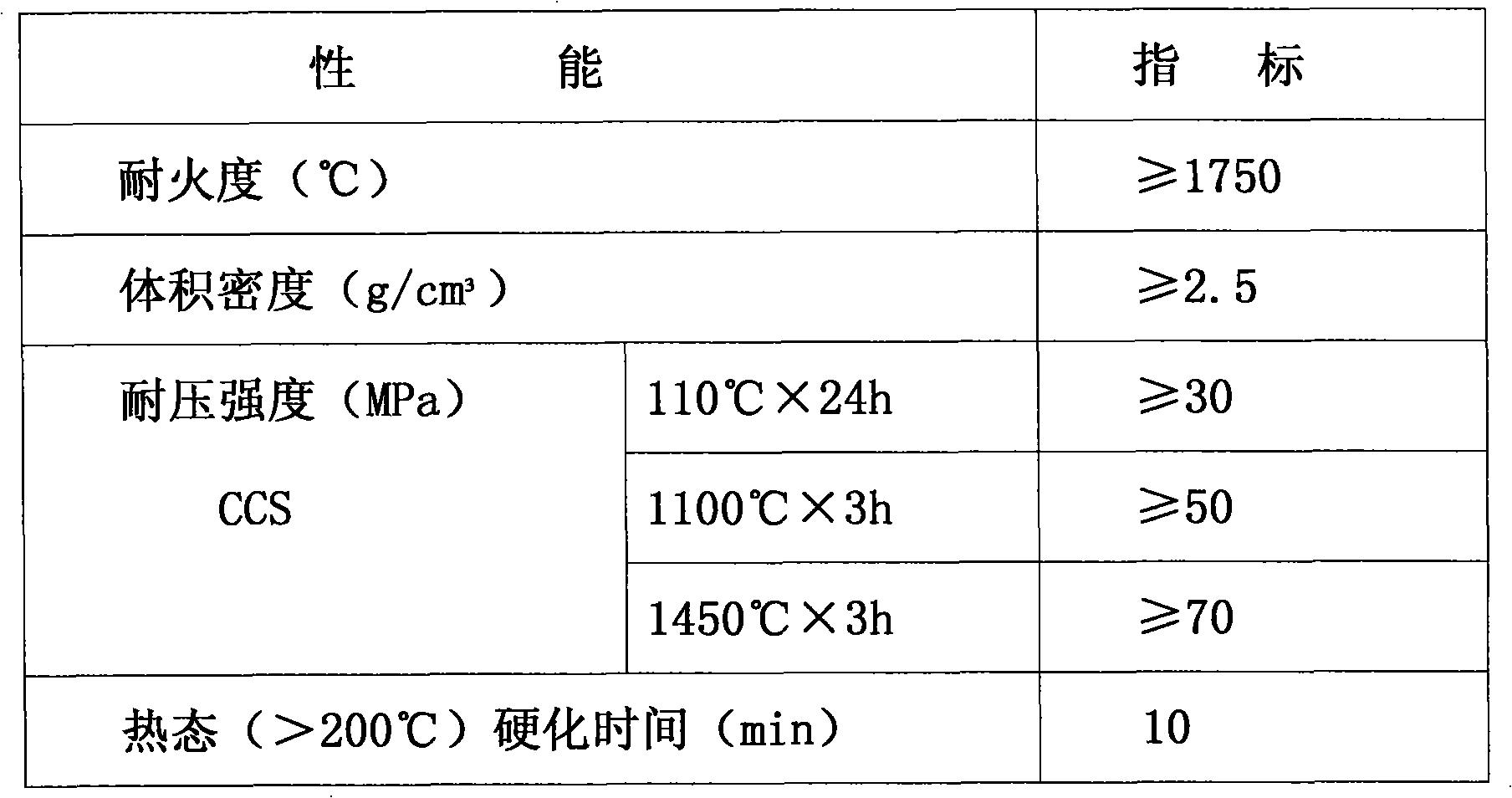

Image

Examples

Embodiment 1

[0017] A spray gun thermal repair material is characterized in that it comprises:

[0018] Mullite with particle size greater than 1.5mm 9%;

[0019] Mullite with particle size greater than 0.09mm 50%;

[0020] Mullite with a particle size of 0.088mm 20%;

[0021] Refractory cement 20%;

[0022] Aluminum dihydrogen phosphate or water glass 1%.

Embodiment 2

[0024] A spray gun thermal repair material is characterized in that it comprises:

[0025] Mullite with particle size greater than 1.5mm 8%;

[0026] Mullite with particle size greater than 0.09mm 51%;

[0027] Mullite with a particle size of 0.088mm 19%;

[0028] Refractory cement 21%;

[0029] Aluminum dihydrogen phosphate or water glass 1%.

Embodiment 3

[0031] A spray gun thermal repair material is characterized in that it comprises:

[0032] Mullite with particle size greater than 1.5mm 9%;

[0033] Mullite with a particle size greater than 0.09mm 49%;

[0034] Mullite with a particle size of 0.088mm 20%;

[0035] Refractory cement 20%;

[0036] Aluminum dihydrogen phosphate or water glass 1%;

[0037] Magnesia 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com