Antibacterial mould-proof-type colored door seal and manufacture method thereof

An antibacterial and mildew-proof, manufacturing method technology, applied to other washing machines, textiles, papermaking, washing devices, etc., can solve door seals that are prone to mildew, low hardness tensile strength, elongation at break, tear resistance, single color tone, etc. problem, to achieve the effect of simple manufacturing method, high tensile strength and reasonable ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

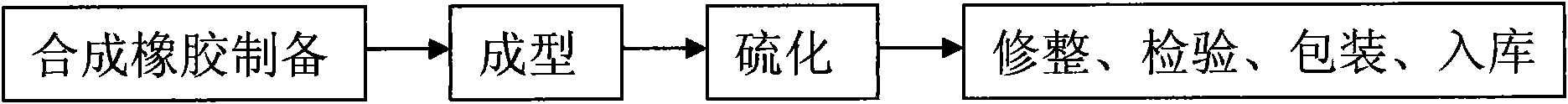

Method used

Image

Examples

Embodiment 1

[0050] An antibacterial and mildew-proof color door seal, the content ratio of each raw material component is as follows in parts by weight:

[0051] EPDM rubber: 150 parts

[0052] Indirect zinc oxide: 4 parts

[0053] Stearic acid: 0.4 parts

[0054] Anti-aging agent: 1 part

[0055] White carbon black: 30 parts

[0056] Sulfur: 0.1 parts

[0057] Accelerator: 3 parts

[0058] Dispersant: 1 part

Embodiment 2

[0060] An antibacterial and mildew-proof color door seal, the content ratio of each raw material component is as follows in parts by weight:

[0061] EPDM rubber: 200 parts

[0062] Indirect zinc oxide: 6 parts

[0063] Stearic acid: 1 part

[0064] Anti-aging agent: 4 parts

[0065] White carbon black: 80 parts

[0066] Sulfur: 1 part

[0067] Accelerator: 6 servings

[0068] Dispersant: 4 parts

Embodiment 3

[0070] An antibacterial and mildew-proof color door seal, the content ratio of each raw material component is as follows in parts by weight:

[0071] EPDM rubber: 180 parts

[0072] Indirect zinc oxide: 5 parts

[0073] Stearic acid: 0.5 parts

[0074] Anti-aging agent: 2 parts

[0075] White carbon black: 60 parts

[0076] Sulfur: 0.5 parts

[0077] Accelerator: 4 parts

[0078] Dispersant: 3.5 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com