Method for controlling variable speed operation curves by low head mitergate hydraulic hoist

A hydraulic hoist and operating curve technology, which is applied in water conservancy projects, coastline protection, sea area engineering, etc., can solve problems such as low accuracy, large energy waste, and large motor power, so as to improve economic and social benefits and maintain Effects of cost reduction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0034] Figure 4 It is a schematic flow chart of the present invention; Figure 5 It is a schematic diagram of the variable speed opening operation curve of the miter gate hoist according to the present invention; Image 6 It is a schematic diagram of the variable speed closing operation curve of the miter gate hoist according to the present invention.

[0035] Such as Figure 4 to Figure 6 Shown: The control method using the variable speed operating curve of the hydraulic gate hoist with low water head includes the following steps:

[0036] (1) Connect the computer with the hydraulic hoist;

[0037] (2) Set the variable speed opening operation curve of the miter gate hoist and the variable speed closing operation curve of the miter gate hoist in the above-mentioned computer;

[0038] Wherein, the variable-speed opening operation curve of the miter gate hoist is divided into two cases, which are respectively:

[0039] 1) When the submerged water depth of the miter gate is...

Embodiment

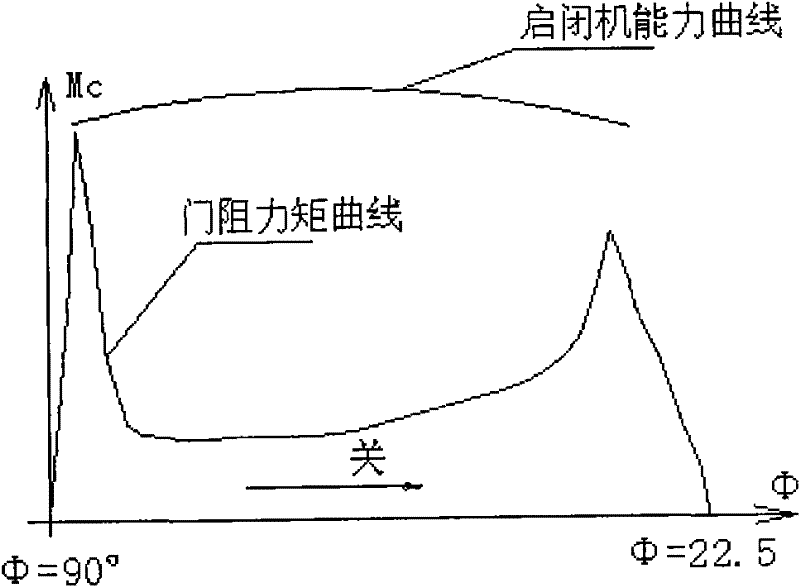

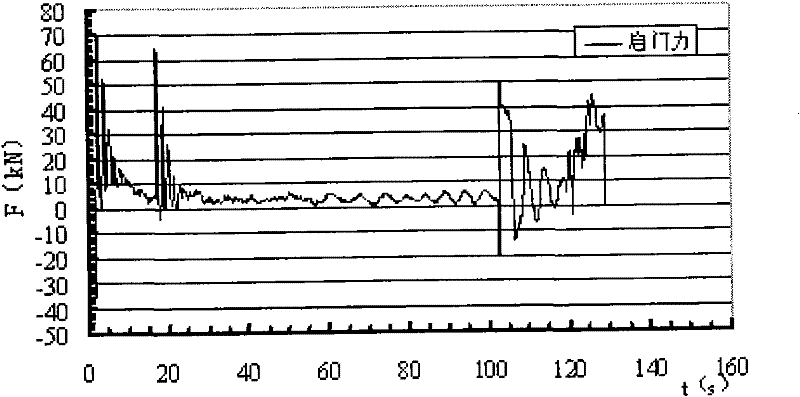

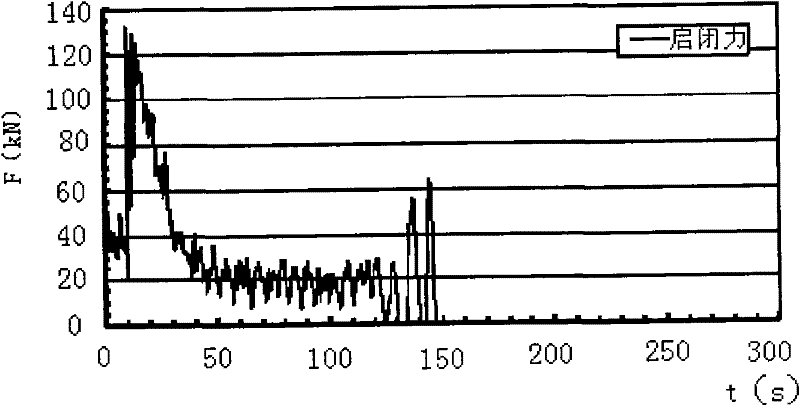

[0046] Embodiment: by the present invention, the speed and the time of closing the gate of Liulaojian three-line ship lock of Beijing-Hangzhou Grand Canal are controlled, and the following results are obtained: Figure 7 The measured opening and closing force curves of Liulaojian third-line ship lock at Liulaojian line and Figure 8 The actual measurement curve of the piston rod running speed of the headstock machine when the Liulaojian third-line ship lock is closed, as well as the Figure 9 with Figure 10 The actual measurement curves of the opening and closing force of the Liulaojian third-line ship lock when it is opened and closed, from Figure 7 with Figure 8 It can be seen that because the time of the slow zone at the beginning and end of the closed door is about 40s, there is basically no angular acceleration during operation, and the slow output frequency is less than 1 / 3 of the fast output frequency, and its slow running speed is 0.6m / min , the fast running spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com