New process for the synthesis of moguisteine

A technology of methyl and methoxyphenoxy, which is applied in the new field of synthesizing mogisteine, which can solve the problems of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

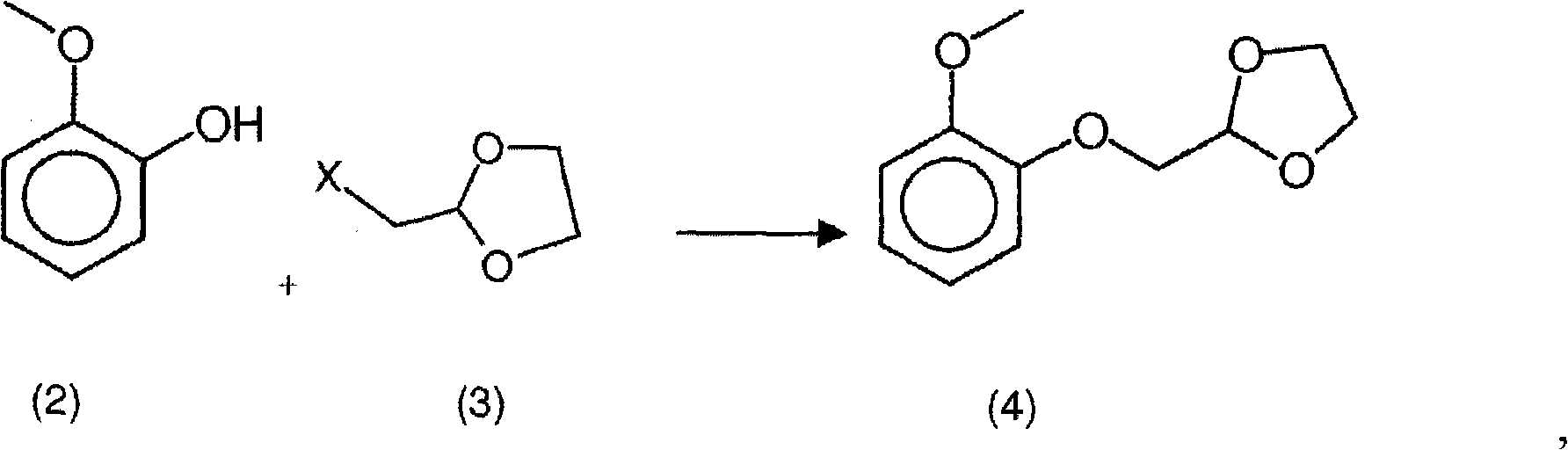

[0070] Step a) Preparation of formula 2-[(2-methoxyphenoxy)methyl]-1,3-dioxolane in 1-methoxy-2-propanol Intermediate of ring (4) (4)

[0071] The raw materials were used in the amounts shown in Table 1 below.

[0072] Table 1: Substances and amounts of Example 1

[0073] raw material

density

g

ml

Moore

The molar ratio of

1.129

297.6

263.6

2.40

1.00

1-methoxy-2-propanol

0.920

607.2

660.0

*

*

497.6

3.60

1.50

97% 2-bromomethyl-1,3-dioxide

Pentacyclic

1.628

475.2

291.9

2.76

1.15

50% KOH solution

1.516

84.2

55.5

0.75

0.31

Deionized water, first serving

1.00

660.0

660.0

*

*

Deionized water, second portion

1.00

1320.0

1320.0

*

*

[0074] raw material

density

g

ml

Moore

The molar ratio of

Deionized water for washing

1.00

2x500

2x500

*

*

[0075] Under a nitrogen atmosphere, load potassium carbonate fine powder and 1-methoxy-2-propanol into a completely dry 6-liter flask a...

Embodiment 2

[0101] Step a) Preparation of formula 2-[(2-methoxyphenoxy)methyl]-1,3-dioxolane in N-methylpyrrolidone Intermediate of ring (4) (4)

[0102] The following raw materials were used in the amounts shown in Table 2.

[0103] Table 2: Substances and amounts used in Example 2

[0104] raw material

density

g

ml

Moore

The molar ratio of

1.129

99.2

87.9

0.80

1.00

N-methylpyrrolidone

1.028

514.0

500.0

*

*

221.14

1.60

2.00

97% 2-bromomethyl-1,3-dioxide

Pentacyclic

1.628

158.4

97.3

0.92

1.15

Deionized water for quenching

1.00

1400.0

1400.0

Toluene for extraction

0.865

692.0

800.0

Deionized water, first wash

1.00

800.0

800.0

30% NaOH solution

1.335

50.0

37.5

Deionized water, second wash

1.00

800.0

800.0

30% NaOH solution

1.335

50.0

37.5

Deionized water, third wash

1.00

800.0

800.0

30% NaOH solution

1.335

50.0

37.5

carbon

5.0

[0105] raw material

density

g

ml

Moore

Th...

Embodiment 3-31

[0116] Step a) Intermediate (4) of formula 2-[(2-methoxyphenoxy)methyl]-1,3-dioxolane (4) preparation

[0117] By following the same procedure as shown in Example 1, but using the amount, reaction solvent, time, and temperature shown in Table 3, intermediate (4) was obtained in the yield and purity shown in Table 4 below.

[0118] Table 3: Reaction conditions of Example 3-31

[0119]

[0120]

[0121]

[0122]

[0123]

[0124] Table 4: Yield and purity of intermediate (4) obtained in Example 3-31

[0125]

[0126]

[0127] Therefore, in all the examples, intermediate (4) was obtained in high yield and with a purity greater than 99%. According to the present invention, the intermediates of Examples 1, 28, 29 and 31 have the best appearance and quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com