Preparation method of dinitrogen trioxide and reaction equipment thereof

A technology of reaction temperature and reaction pressure, applied in the direction of dinitrogen trioxide, nitrogen oxides/oxyacids, etc., can solve the problem of ineffective control of the oxidation composition of nitrogen oxides, achieve short reaction time, simple reaction equipment, and raw materials High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

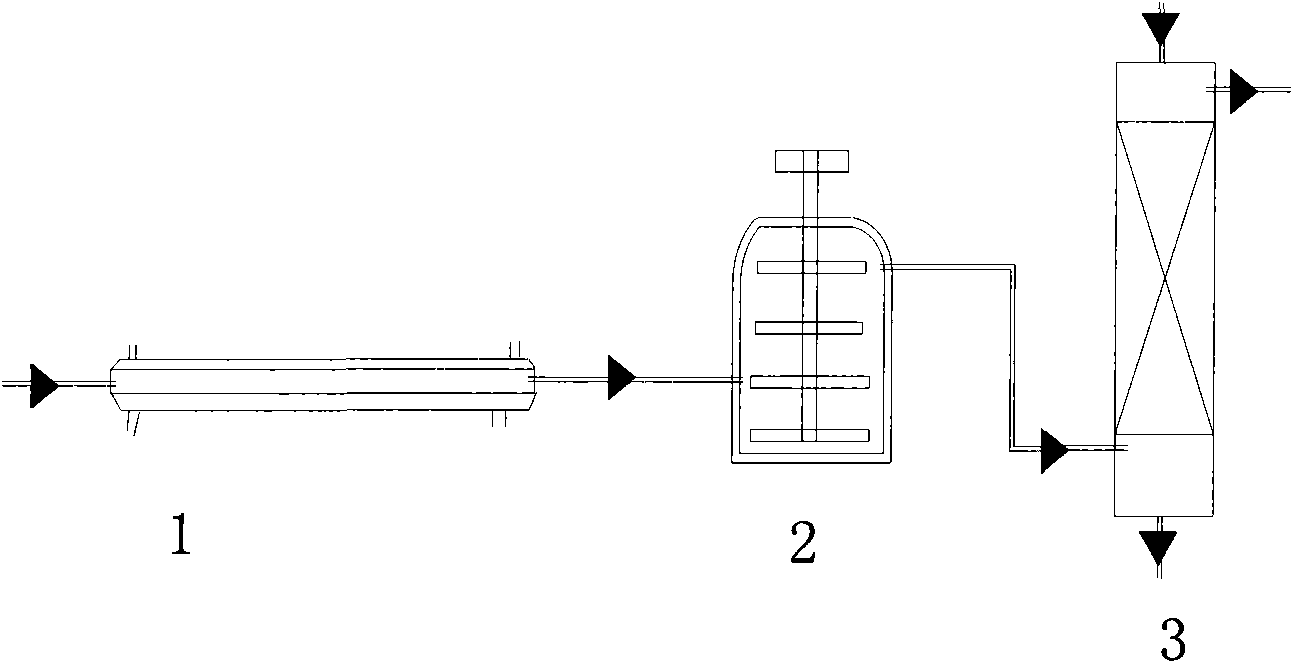

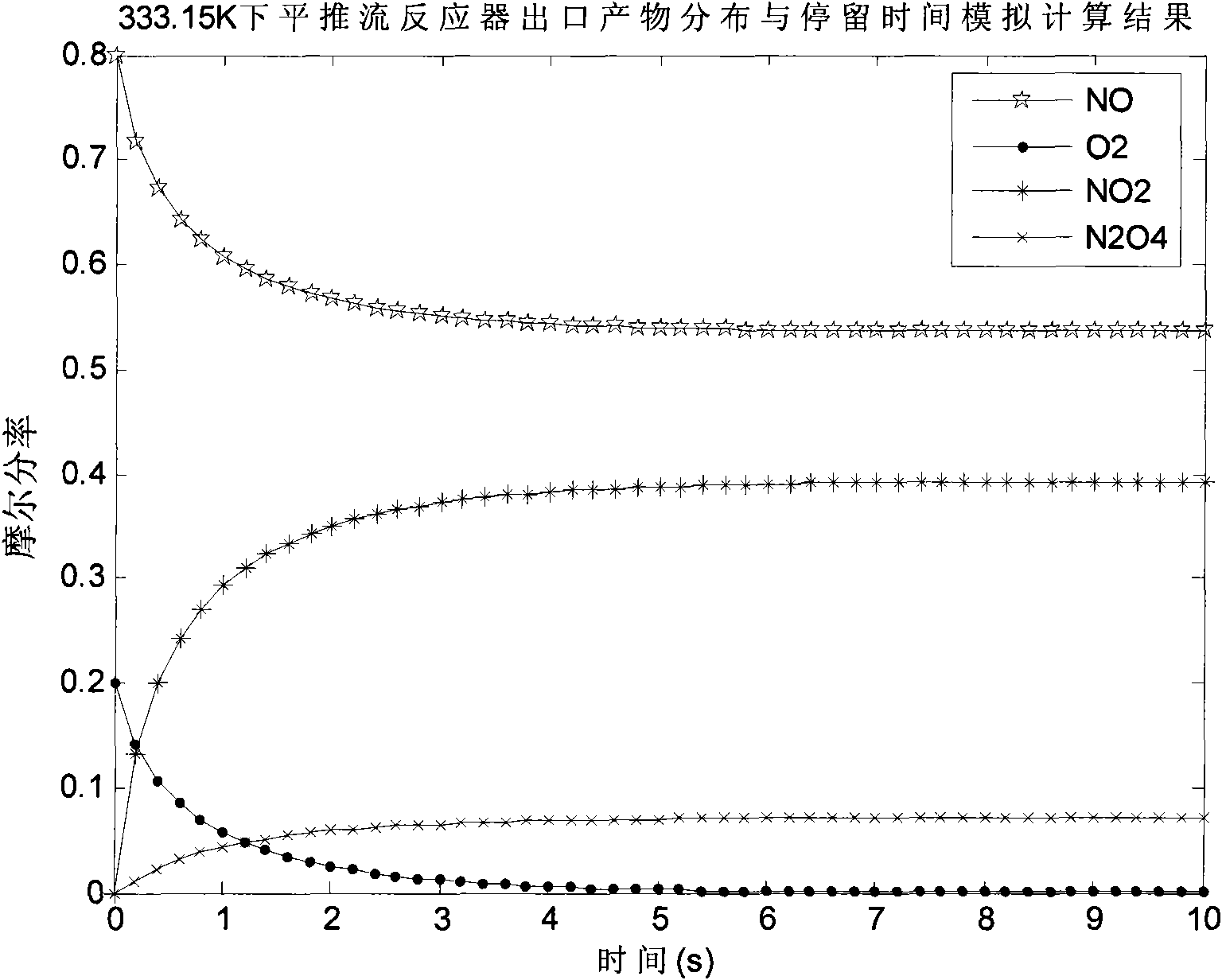

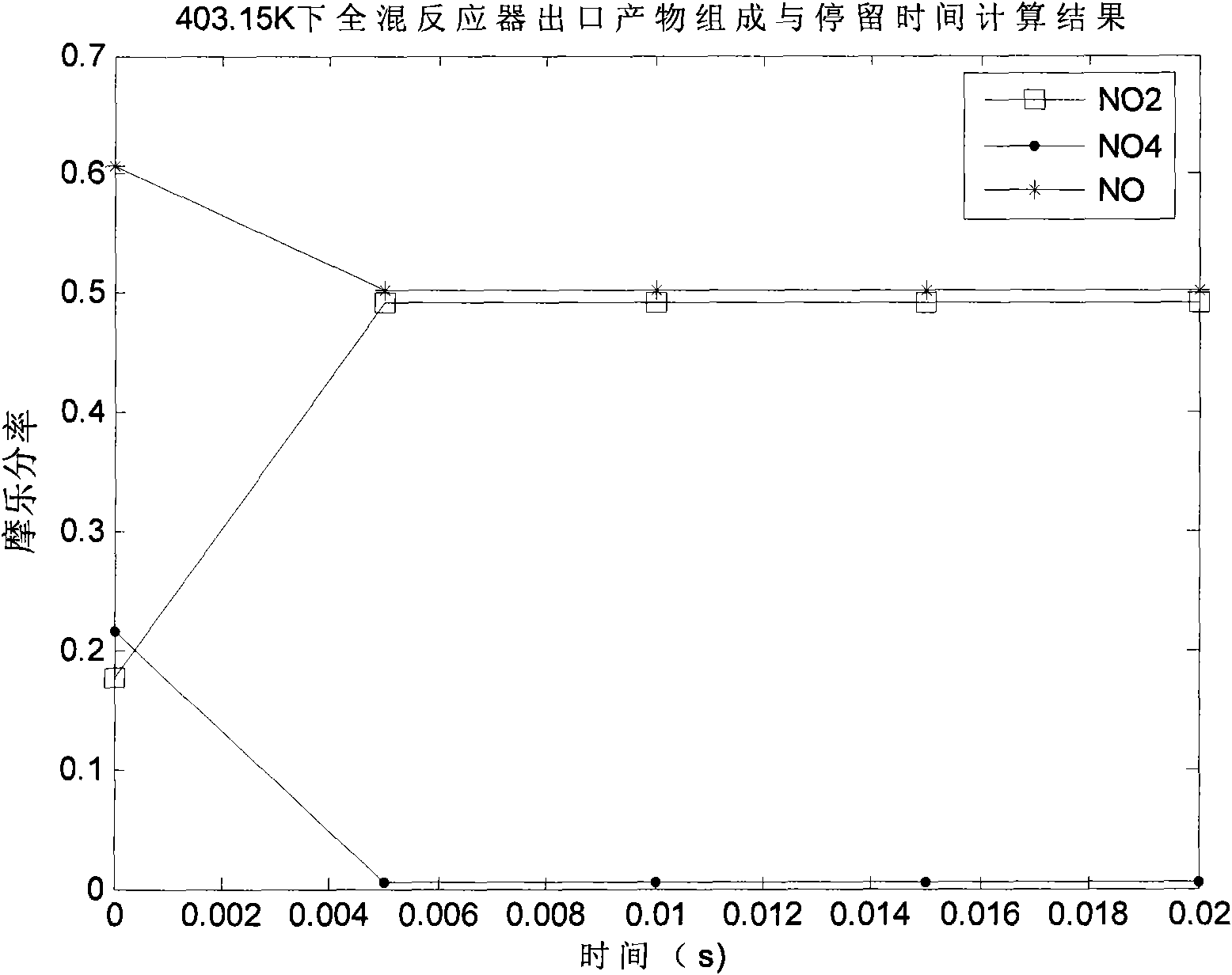

[0053] The present invention is carried out in plug-flow isothermal reactors, fully mixed isothermal reactors and packed towers. The plug-flow isothermal reactor is made of quartz glass with an inner diameter of 25mm and a tube length of 250mm; the fully mixed isothermal reaction also uses quartz glass with an inner diameter of 150mm and a height of 250mm, and a stirring paddle is added to accelerate the full mixing (paddle or anchor stirring) device, about 250 to 300 rpm); the esterification packed tower is a stainless steel pipe with an inner diameter of 25mm and a pipe length of 1000mm, filled with different types of fillers. There is a casing outside the three devices, and the constant temperature water of different temperatures provided by the constant temperature water bath is respectively introduced into the casing. Experimental conditions: the pressures of plug flow reactor, fully mixed reactor and esterification packed tower are respectively: 0.2Mpa, 0.1Mpa and 0.1Mpa...

Embodiment 2

[0057] Embodiment 2: other conditions are identical with embodiment 1, be porcelain Raschig ring (Dg25) in the esterification packing tower, and temperature is 100 ℃, changes O 2 The amount of feed, thus changing the NO and O 2 Ratio of feed to prepare methyl nitrite.

[0058] Table 2: NO and O 2 Comparison of the yield of methyl nitrite under the feed ratio

[0059]

[0060] NO and O 2 Feed ratio Methyl nitrite yield (%)

[0061]

[0062] 4:1 99.38

[0063] 4.5:1 99.39

[0064] 5:1 99.39

[0065]

Embodiment 3

[0066] Embodiment 3: Other conditions are the same as in Implementation 1, the esterification packed tower is made of porcelain Raschig rings (Dg25), the temperature is 100° C., and the nitrogen feed flow rate is changed to prepare methyl nitrite.

[0067] Table 3: Comparison of methyl nitrite yields under different nitrogen feed rates

[0068]

[0069] Feed amount of nitrogen (ml / min) Methyl nitrite yield (%)

[0070]

[0071] 20 99.66

[0072] 60 98.65

[0073] 100 97.50

[0074] 120 97.36

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com