Ozonized water treatment method taking nano zinc oxide as catalyst

A nano-zinc oxide and ozonated water technology, applied in the directions of oxidized water/sewage treatment, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as insufficient research scope, and achieve The effect of accelerated degradation rate and increased degree of mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

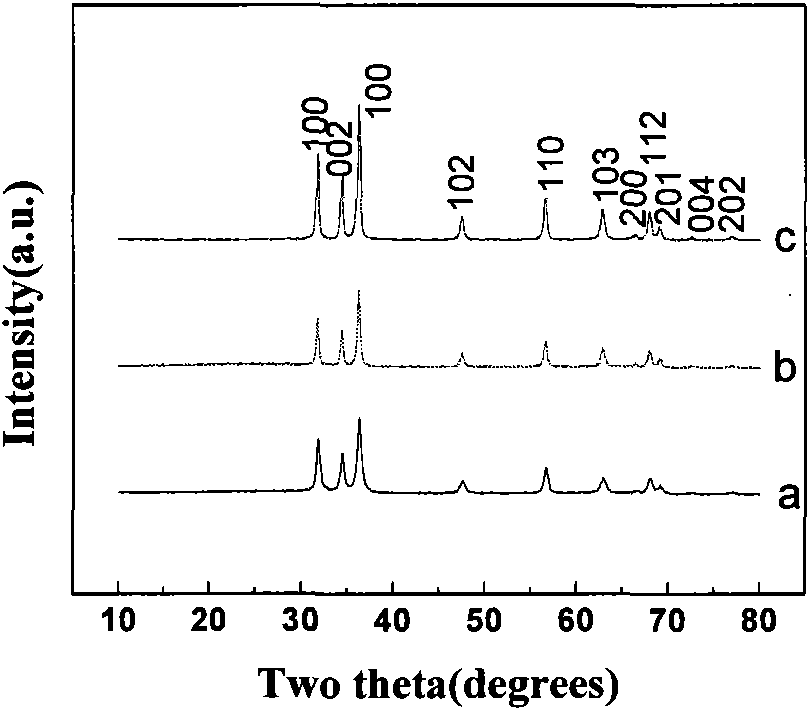

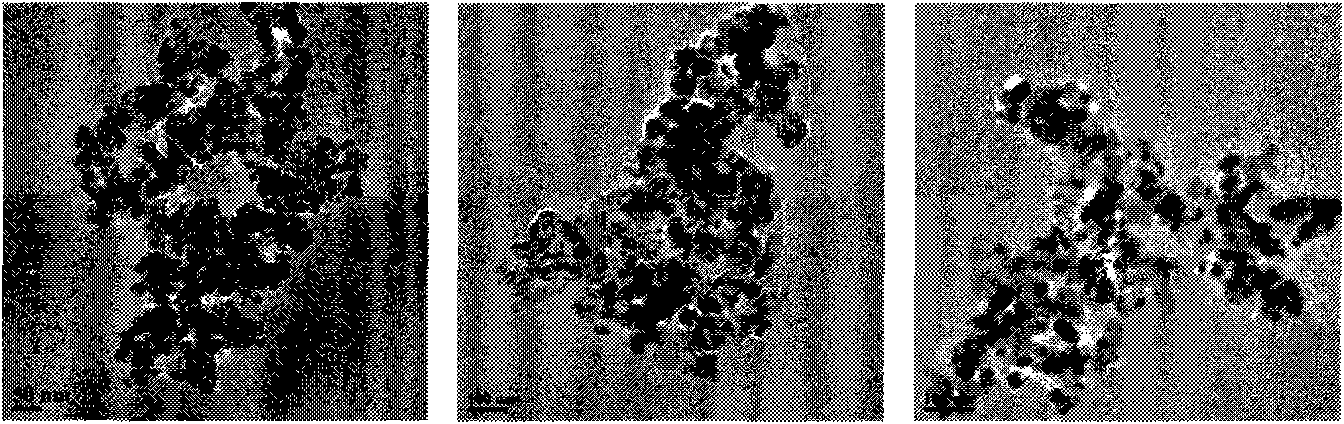

[0022] Weigh 55.0g Zn(CH 3 COO) 2 2H 2 O was dissolved in a beaker filled with 500ml deionized water, and 6.0mol / L ammonia water was added dropwise to it under vigorous stirring until the pH was about 10. During this process, the solution first changed from clear and transparent to viscous milky white suspension Then it became a clear and transparent solution. Cover the beaker with filter paper and continue to stir for 72h. After stopping the stirring, take out the white precipitate in the beaker, wash it with deionized water several times, put it in an oven, dry at 60°C for 12h, and grind Afterwards, three crucibles were put into the muffle furnace respectively, and the temperature was raised to 150°C, 200°C and 300°C at a rate of 2°C / min, respectively, and then calcined for 2 hours to obtain ZnO sample a, ZnO sample b and ZnO sample c. Its XRD see figure 1 , electron microscope photo see figure 2 .

Embodiment 2

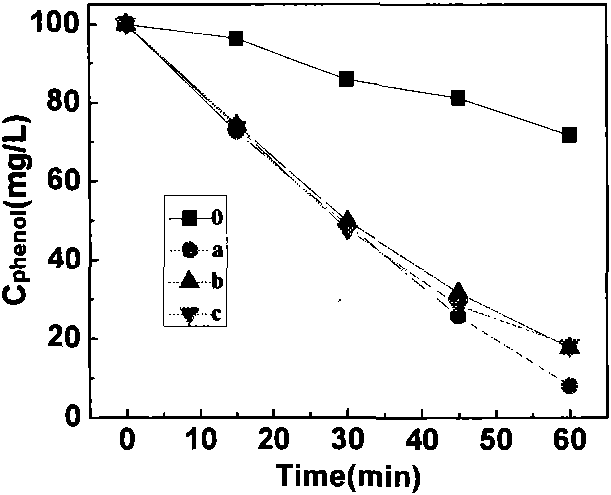

[0024] The initial concentration of phenol in 200ml is 100mg L -1 In the simulated wastewater, add 0.20g of nano-zinc oxide sample a, start stirring, and pass ozone flow rate of 0.50mg min at the reaction temperature of 20°C -1 Ozone, record the concentration of phenol at different times. The result is as image 3 As shown, line 0 is ozonation alone (no catalyst), and line a is catalytic ozonation of nano-zinc oxide sample a. It indicated that the addition of nano-zinc oxide significantly promoted the degradation of phenol.

Embodiment 3

[0026] The initial concentration of phenol in 200ml is 100mg L -1 Add 0.20g of nano-zinc oxide sample b to the simulated wastewater, start stirring, and pass the ozone flow rate of 0.50mg min at the reaction temperature of 20°C -1 Ozone, record the concentration of phenol at different times. The result is as image 3 As shown, line 0 is ozonation alone (no catalyst), and line b is ozonation catalyzed by nano-zinc oxide sample b. It indicated that the addition of nano-zinc oxide significantly promoted the degradation of phenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com