Synthesis method of m-phenoxytoluene

A m-phenoxytoluene, synthetic method technology, applied in the formation/introduction of ether group/acetal group/ketal group, ether preparation, organic chemistry, etc., can solve the problems of long steps and low total yield, etc. To achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

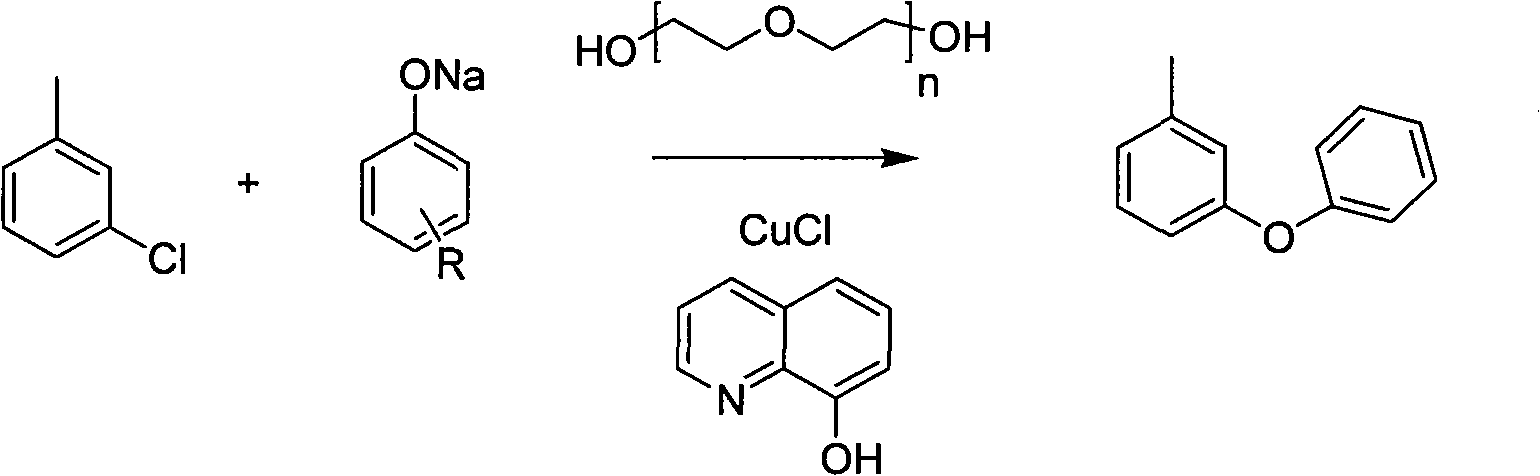

[0012] Concrete reaction formula of the present invention is:

[0013]

[0014] In the formula, It means polydiethylene glycol, and any degree of polymerization can play a catalytic effect. The reaction condition is heating. The reaction equation shows: different substituted sodium phenates suitable for this method.

[0015] Specific steps are as follows:

[0016] 1. Put 126.5g of m-chlorotoluene, 23.2g of sodium phenoxide, 42g of cuprous chloride, 4.1g of 8-hydroxyquinoline, and 4.0g of polydiethylene glycol into a 500mL round bottom flask, and stir at room temperature for 5±1 minutes;

[0017] 2. Heat the mixture to 130-140°C while stirring;

[0018] 3. Insulate and stir the mixture at 130-140°C for 8-9 hours;

[0019] 4. After the reaction is over, high vacuum distillation (14-16 mmHg) is carried out, and the fraction at 100-110° C. can be obtained to obtain the final compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com