Spherical composite catalyst for olefin coordination polymerization, preparation method and application thereof

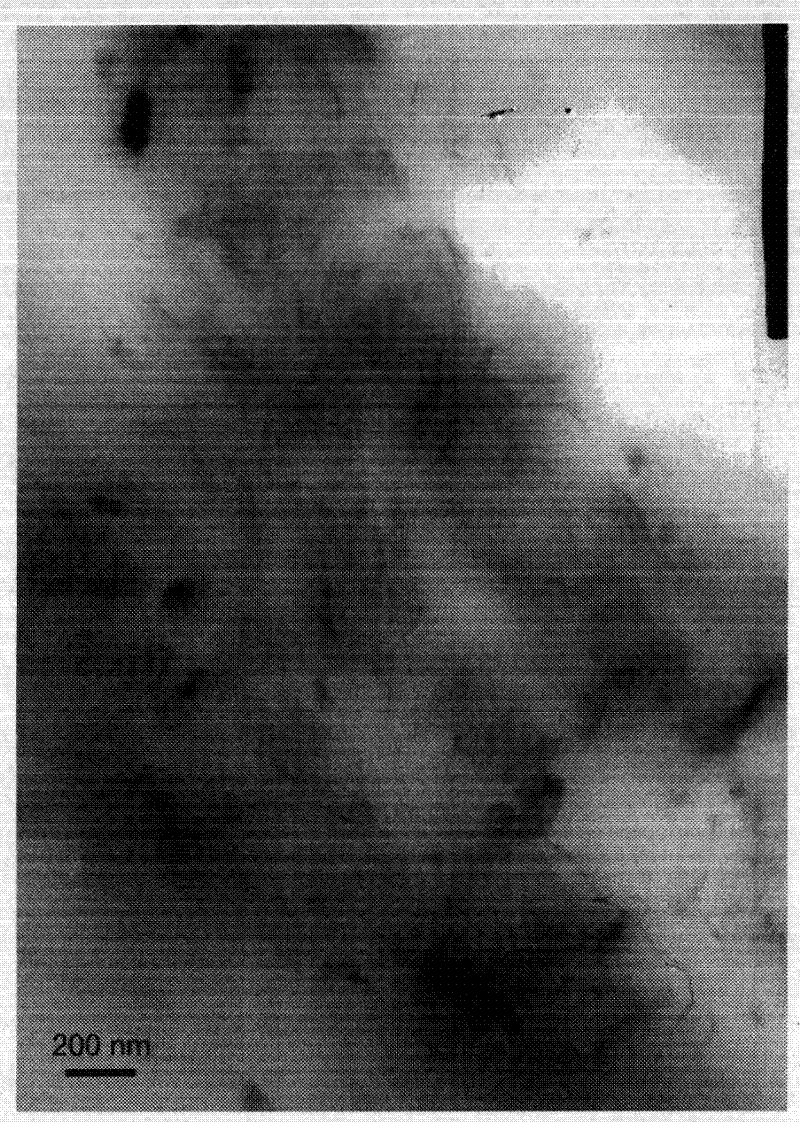

A technology of composite catalyst and coordination polymerization, which is applied in the preparation of spherical nanocomposites of polyolefin and clay, spherical composite catalysts for olefin coordination polymerization and their preparation, and can solve problems such as the inability to prepare spherical composite catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation of the hydrochloric acid ethanol mixed solution of 1-hexadecyl-3-bromoimidazolium salt: take by weighing 5 grams of 1-hexadecyl-3-bromoimidazolium salt, add the mixed solution of 11 milliliters of hydrochloric acid ethanol (by mass Concentrated hydrochloric acid with a concentration of 36% and ethanol at a volume ratio of 1:9 was prepared), stirred at 50° C. for 1 hour and set aside.

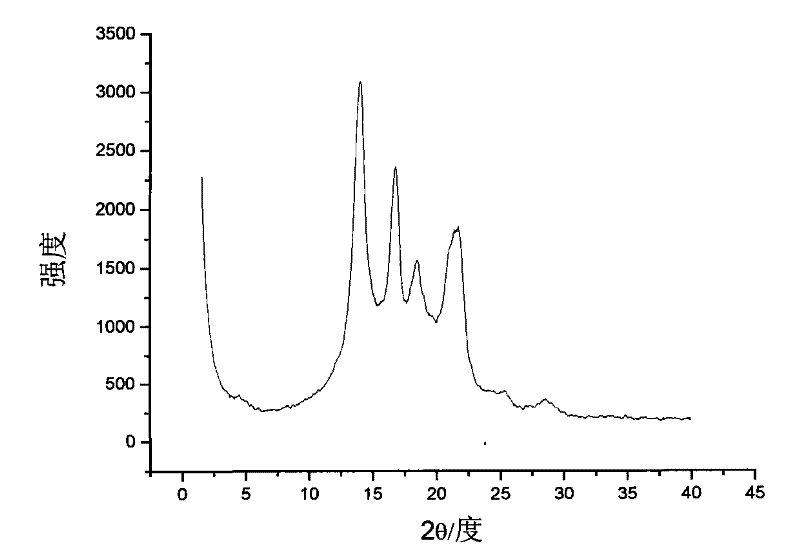

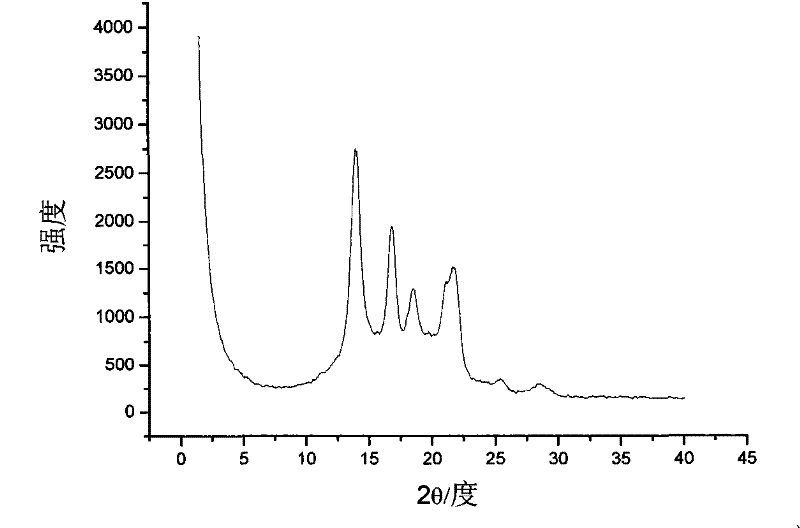

[0055] Preparation of organically modified clay: 50 grams of sodium-montmorillonite was added to 500 milliliters of distilled water, stirred at 30 ° C for 20 hours, and then the hydrochloric acid ethanol of the above-mentioned 1-hexadecyl-3-bromoimidazolium salt was mixed Add the solution to the above-mentioned sodium-montmorillonite aqueous dispersion; stir vigorously for 24 hours, filter with suction, and wash the filtrate repeatedly with a mixture of ethanol and water (volume ratio: 1:1) until AgNO 3 Check that there is no precipitate in the filtrate. The filtrate was ...

Embodiment 2

[0060] The preparation of the hydrochloric acid ethanol mixed solution of 1-hexadecyl-3-iodoimidazolium salt: take by weighing the 1-hexadecyl-3-iodoimidazolium salt of 50.0 grams, add the mixed solution of 13 milliliters of hydrochloric acid ethanol (according to Concentrated hydrochloric acid with a mass concentration of 36% and ethanol at a volume ratio of 1:9 was prepared), stirred at 50° C. for 1 hour and set aside.

[0061] Preparation of organically modified clay: Stir 5 grams of K-montmorillonite in 500 milliliters of distilled water at 60°C for 20 hours, then add the above-mentioned 1-hexadecyl-3-iodoimidazolium hydrochloric acid ethanol mixed solution to the above In the aqueous dispersion of K-montmorillonite; stir vigorously for 24 hours, filter with suction, and wash the filtrate repeatedly with a mixture of ethanol and water (volume ratio: 1:1) until AgNO 3 Check that there is no precipitate in the filtrate. Then vacuum dry at 100°C for 2 hours, grind the dried ...

Embodiment 3

[0066] Preparation of the hydrochloric acid ethanol mixed solution of 1-hexadecyl-3-chloroimidazolium salt: take 5 grams of 1-hexadecyl-3-chloroimidazolium salt, add 13 milliliters of hydrochloric acid ethanol mixed solution (according to Concentrated hydrochloric acid with a mass concentration of 36% and ethanol at a volume ratio of 1:9 was prepared), stirred at 50° C. for 1 hour and set aside.

[0067] Preparation of organically modified clay: 5 grams of sodium-montmorillonite was stirred in 500 milliliters of distilled water at 60° C. for 20 hours, and then the hydrochloric acid ethanol mixed solution of the above-mentioned 1-hexadecyl-3-chloroimidazolium salt was added to the above-mentioned Sodium-montmorillonite aqueous dispersion; stir vigorously for 24 hours, filter with suction, and wash the filtrate repeatedly with a mixture of ethanol and water (volume ratio: 1:1) until AgNO 3 Check that there is no precipitate in the filtrate. Then vacuum-dry at 100°C for 2 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com