Bentonite grease

A kind of bentonite lubricating grease and lubricating grease technology, which is applied in the field of bentonite lubricating grease, can solve the problems of poor oxidation resistance, etc., and achieve the effects of good corrosion resistance, convenient product differentiation, and good oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

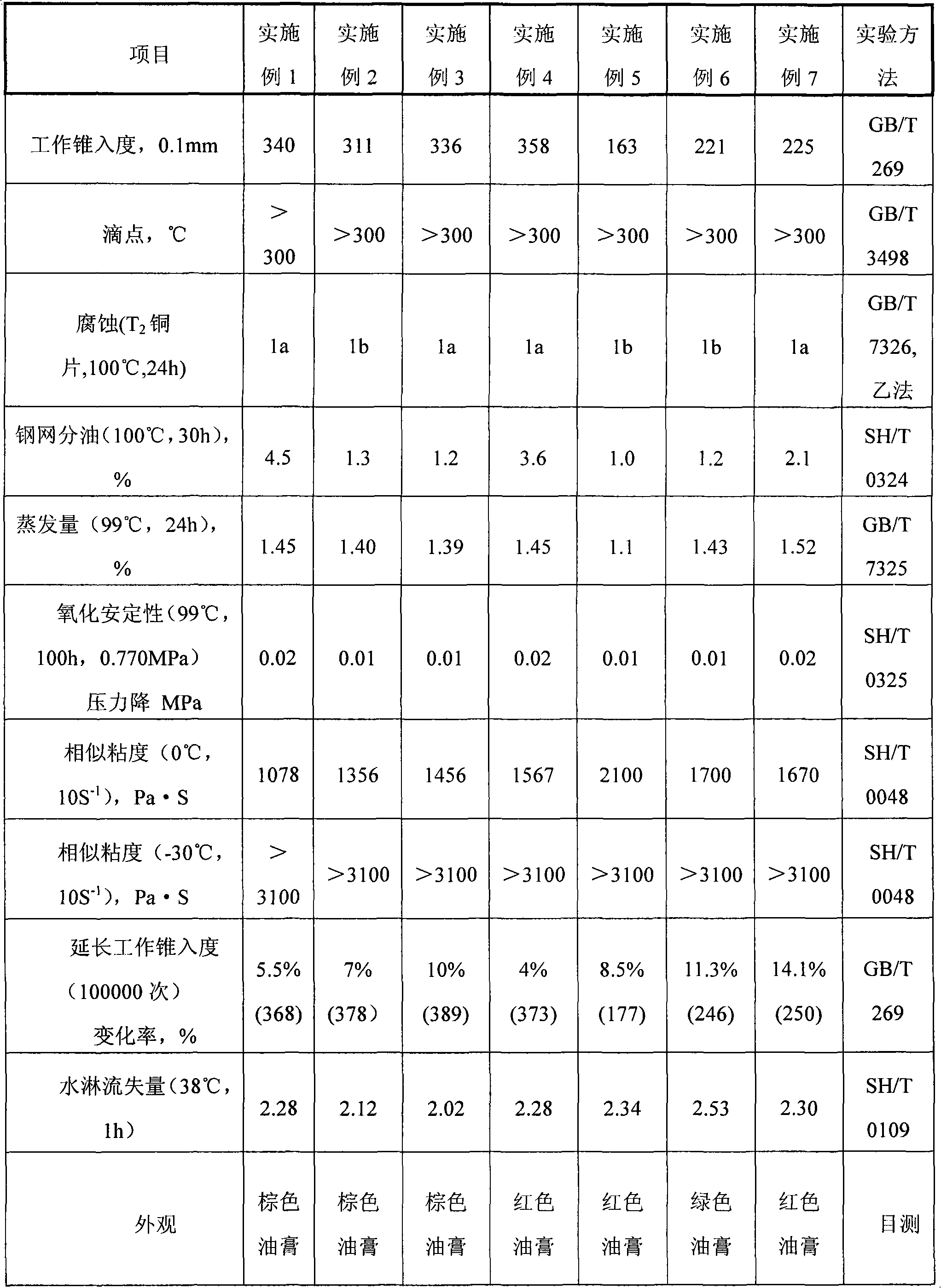

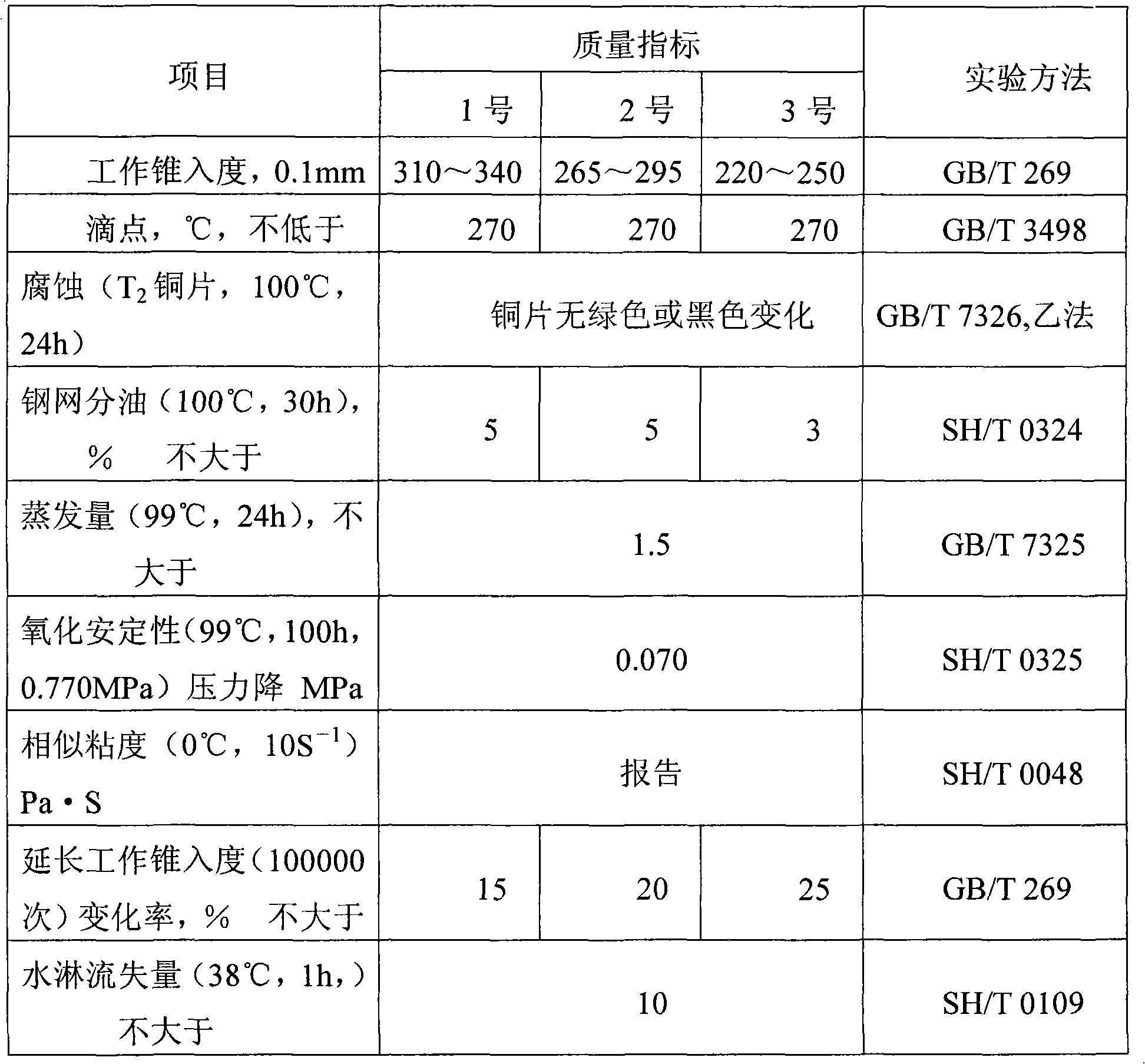

[0033] Embodiment 1, the preparation of the bentonite grease that is made up of grease base oil, thickener and polar dispersant

[0034] Slowly add 4g of organic bentonite 801-B (Qinghong Chemical Auxiliary Factory, Lin’an City, Zhejiang Province) into 46g of furfural refined oil of naphthenic crude oil (viscosity at 100°C: 19.7cst), stir fully to disperse organic bentonite evenly in the oil In, then add 2.17g acetone to the system, and stir rapidly, finally obtain the bentonite lubricating grease that is made up of the furfural refined oil of naphthenic crude oil, organic bentonite and acetone through grinding and degassing, and their mass-number ratio is 46:4 : 2.2. Its characteristics are shown in Table 1.

Embodiment 2

[0035] Embodiment 2, preparation of bentonite grease composed of grease base oil, thickener, polar dispersant and antioxidant

[0036] Add 1.2g of 4,4'-diisooctyldiphenylamine into 182g (100°C viscosity of 19.7cst) furfural refined oil of naphthenic crude oil and stir, and after uniform dispersion, 18g of organobentonite 801-B (Zhejiang Province Lin'an Qinghong Chemical Auxiliary Factory) slowly added into the system, fully stirred to disperse organic bentonite evenly in the oil, then added 9.77g of acetone to the system, and stirred rapidly, and finally obtained furfural from naphthenic crude oil by grinding and degassing The bentonite lubricating grease composed of refined oil, organic bentonite, acetone and 4,4'-diisooctyldiphenylamine has a mass-number ratio of 182:18:9.77:1.2. Its characteristics are shown in Table 1.

Embodiment 3

[0037] Embodiment 3, the preparation of the bentonite grease that is made up of grease base oil, thickener, polar dispersant, antioxidant and pigment

[0038] Add 0.06g of Sudan III and 1.2g of 4,4'-diisooctyldiphenylamine to 182g (viscosity at 100°C of 19.7cst) of furfural refined oil of naphthenic crude oil and stir. After dispersing evenly, mix 18g of organic bentonite 801 -B (Qinghong Chemical Auxiliary Factory, Lin'an City, Zhejiang Province) is slowly added to the system, fully stirred to disperse the organic bentonite evenly in the oil, then added 9.77g of acetone to the system, and stirred rapidly, and finally degassed by grinding to obtain the The bentonite lubricating grease composed of furfural refined oil of alkyl crude oil, organic bentonite, acetone, 4,4'-diisooctyldiphenylamine and Sudan III is 182:18:9.77:1.2:0.06 in parts by mass. Its characteristics are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com