Method for preparing instant purple sweet potato microcapsule full powder

A technology of purple sweet potato and microcapsules, which is applied in the directions of food preparation, application, food science, etc., to achieve the effect of easy operation, simple technological process, and improvement of liver function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

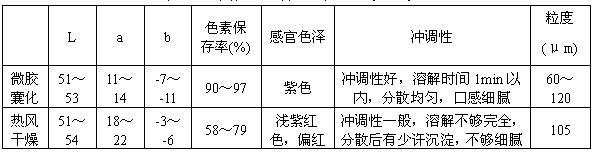

[0028] The preparation method of the present embodiment instant purple sweet potato microcapsule powder comprises the following main steps:

[0029] (1) Pretreatment: Select fresh Southern Purple Potato 008 without rot, scars, and mildew spots, and wash it with clean water to remove impurities such as silt on the surface;

[0030] (2) Beating: Slice the pretreated purple sweet potato, control the thickness of 2mm, add water twice the weight of the sweet potato, and beat it with a beater to make mud. );

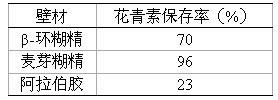

[0031](3) Prepare wall material solution: While beating, prepare a mixed solution containing ascorbic acid and maltodextrin (DE value 20) (as a wall material), in which the concentration of L-ascorbic acid is 1% (referring to the mixed solution The percentage by weight, the same below), the concentration of maltodextrin is 3%;

[0032] (4), mixing and homogenizing: mix the purple sweet potato puree obtained in step (2) and the mixed solution prepared in (3) at a weight ratio...

Embodiment 2

[0038] The preparation method of the present embodiment instant purple sweet potato microcapsule powder comprises the following major steps:

[0039] (1) Pretreatment: Select about 1 kg of fresh Sichuan purple sweet potatoes without rot, scars, and mildew spots, and wash them with clean water to remove impurities such as silt on the surface;

[0040] (2) Beating: Slice the pretreated purple sweet potato, control the thickness of 3mm, add water 3 times the weight of sweet potato, and beat it with a beater to make mud. );

[0041] (3) Prepare wall material solution: While beating, prepare a mixed solution containing ascorbic acid and maltodextrin (DE value 20) (as a wall material), in which the concentration of L-ascorbic acid is 0.8% (referring to the mixed solution The percentage by weight, the same below), the concentration of maltodextrin is 5%;

[0042] (4) Mixing and homogenization: Mix the purple sweet potato puree obtained in step (2) and the mixed solution prepared in...

Embodiment 3

[0048] The preparation method of the present embodiment instant purple sweet potato microcapsule powder comprises the following major steps:

[0049] (1) Pretreatment: Select about 1 kg of fresh Sichuan purple sweet potatoes without rot, scars, and mildew spots, and wash them with clean water to remove impurities such as silt on the surface;

[0050] (2) Beating: Slice the pretreated purple sweet potato, control the thickness of 4mm, add water 4 times the weight of sweet potato, and beat it with a beater to make mud. );

[0051] (3) Prepare wall material solution: While beating, prepare a mixed solution containing ascorbic acid and maltodextrin (DE value 20) (as a wall material), in which the concentration of L-ascorbic acid is 0.6% (referring to the mixed solution The percentage by weight, the same below), the concentration of maltodextrin is 7%;

[0052] (4) Mixing and homogenization: Mix the purple sweet potato mash obtained in step (2) and the mixed solution prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com