Manufacturing method of pattern ring of segmented mold of radial tyre

A technology of radial tires and active molds, which is applied in the direction of manufacturing tools, milling machine equipment details, metal processing equipment, etc., can solve complex and changeable problems that cannot meet tire specifications and pattern forms, etc., to improve interchangeability and get rid of thermal deformation Problem, effect of relative position relationship guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

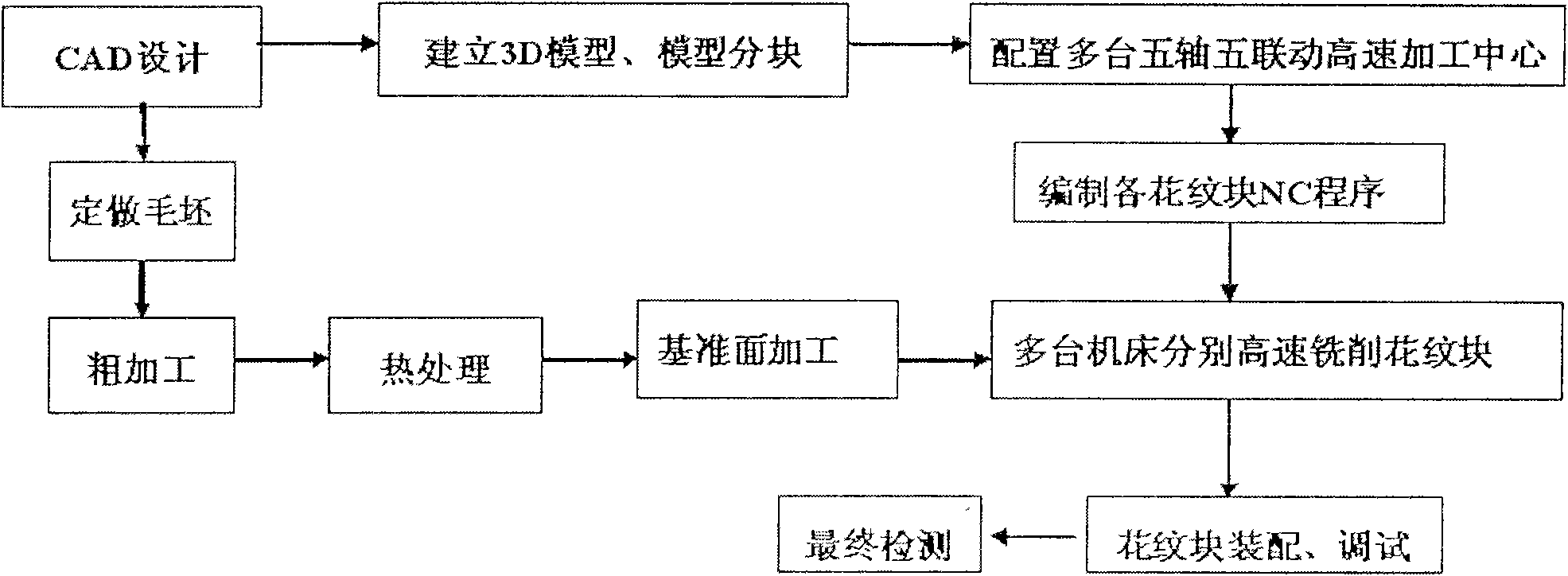

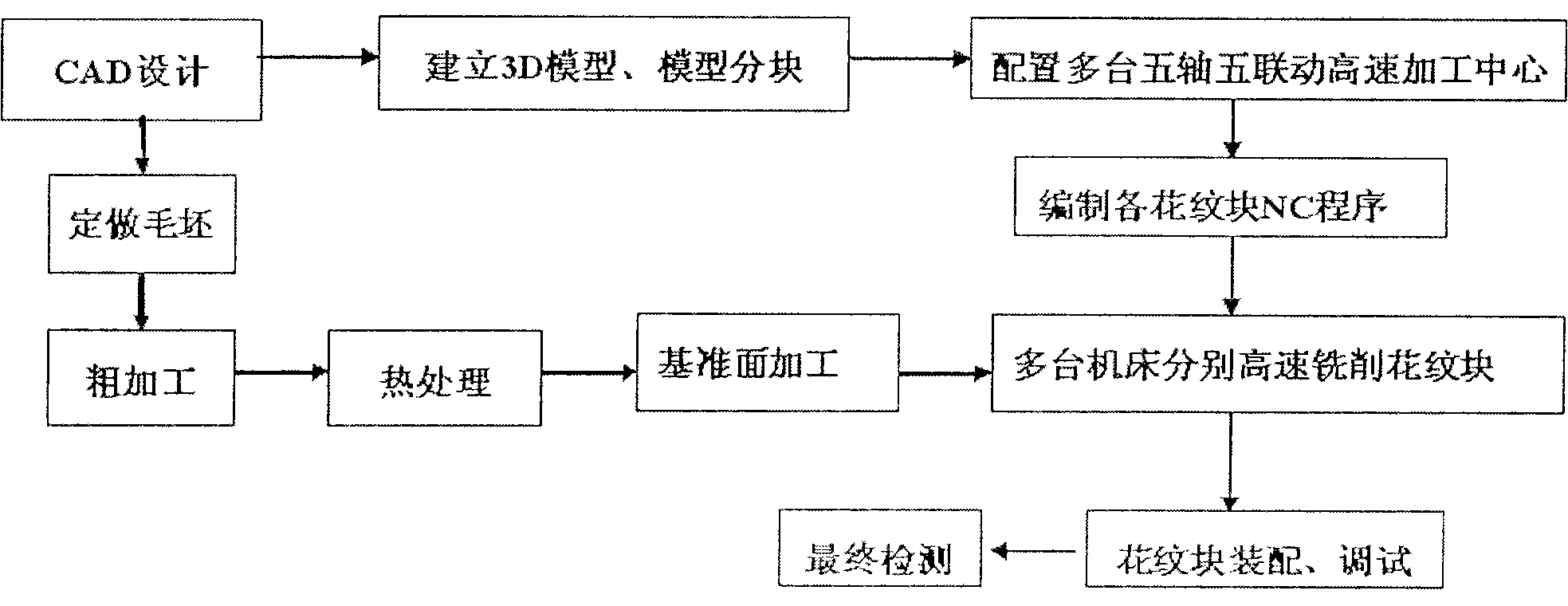

[0020] As shown in accompanying drawing, a kind of manufacture method of radial tire active mold pattern circle, it comprises the following steps:

[0021] (1) Carry out CAD design to the pattern circle, and establish the 3D model of the pattern circle. Divide the 3D model into corresponding single pattern blocks as required, which can be set to 10 pattern blocks. At the same time, the blank of the pattern circle is customized, and the preparatory work such as rough machining, heat treatment, and datum surface processing of the pattern circle is completed.

[0022] (2) Configure 10 sets of five-axis linkage high-speed machining centers to prepare for production: adjust the ambient temperature and humidity of the machine tool and the cooling water temperature and air pressure required by the equipment; All the tools are preset correctly; the workpiece is clamped to the correct position, and the clamping is firm. In this way, the workpiece can be clamped and processed in place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com