Production technology of silver plate inlaid with gold and combined die for same

A production process, gold and silver technology, applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of weak combination of gold and silver plates, complicated embossing process, low production efficiency, etc., to achieve unique appearance, The effect of short processing cycle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention is described in detail through the examples, but not limited by the examples.

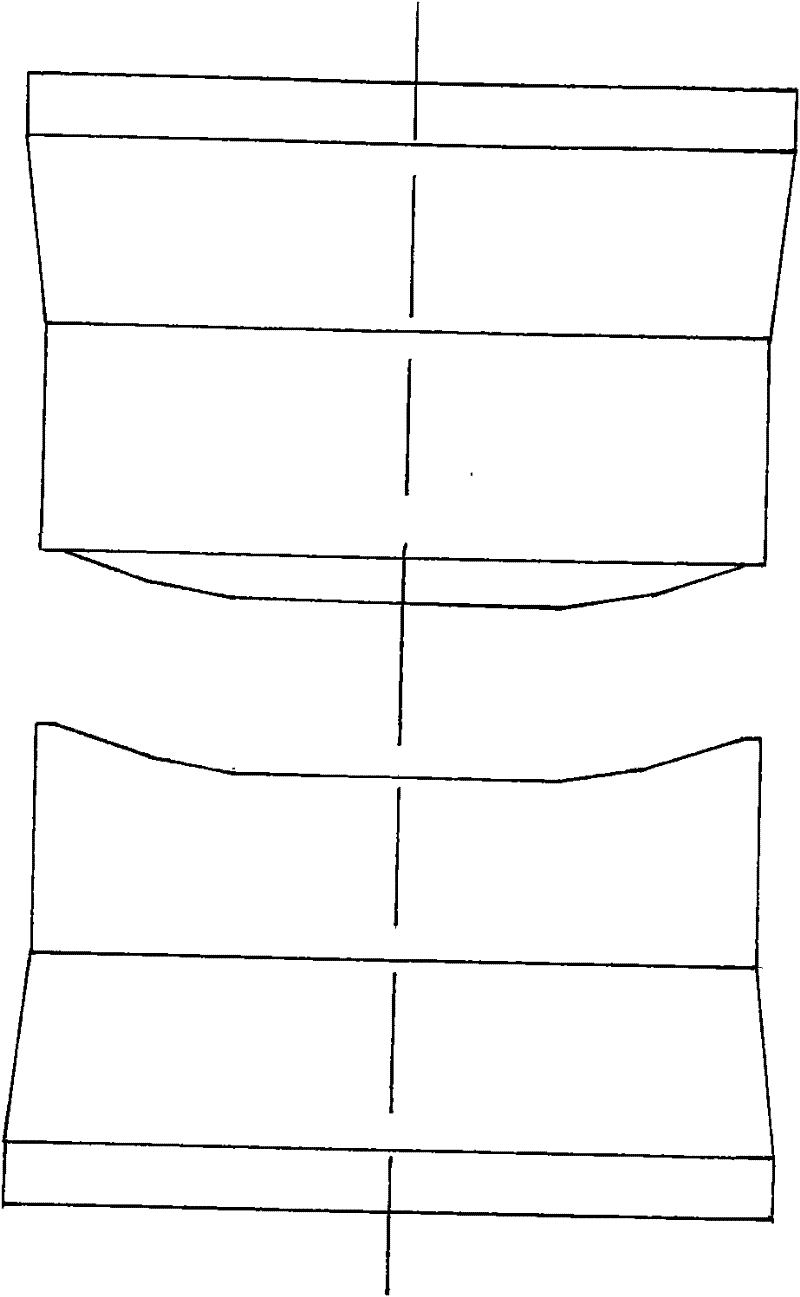

[0027] The present invention takes the preparation of a Φ120 inlaid gold and silver dish as an example, the outer diameter of the gold and silver inlaid dish is 120 mm, and the diameter of the inlaid gold sheet is 37 mm. First, select the parameters of the designed gold and silver plate, and use the three-dimensional relief design software to design and generate the curved surface shape parameters of the convex and concave die sides of the gold and silver plate, such as radius, in order to make the disc mold fit better when imprinting Well, the product pattern is fully pressed, so when designing the radius of the lateral surface of the gold and silver plate, the surface radii of the punch and die are designed to be different values, that is, the radius of the surface of the punch is 97.847mm, and the radius of the surface of the die is 97.847mm. The surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com