Automotive energy-saving emission-reducing hydraulic retarder

A hydraulic retarder, energy saving and emission reduction technology, applied in the direction of brakes, vehicle components, control devices, etc., can solve the problems of loss and failure to perfectly replace the hydraulic retarder, and achieve the effect of reducing the kinetic energy of the recovery vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

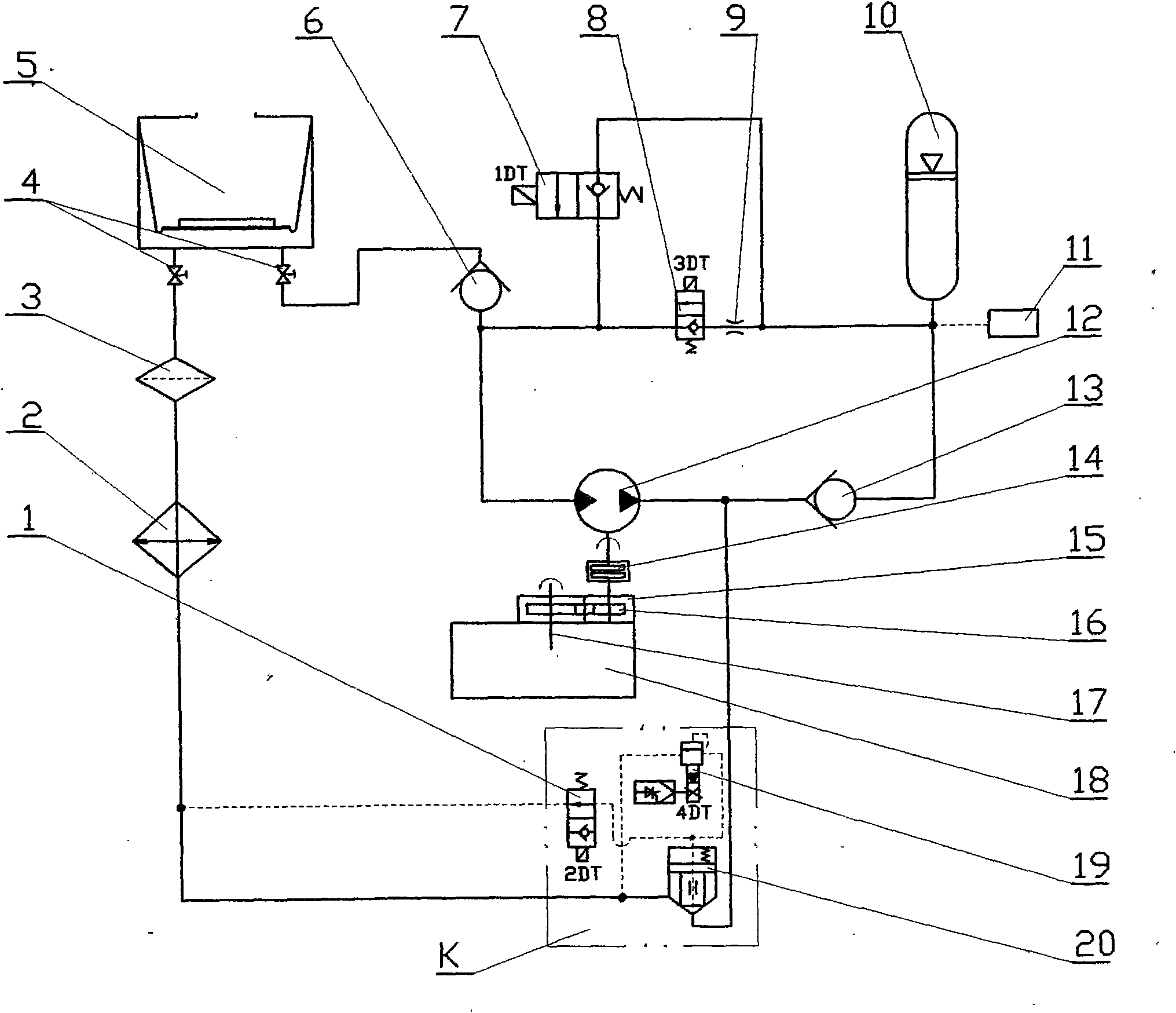

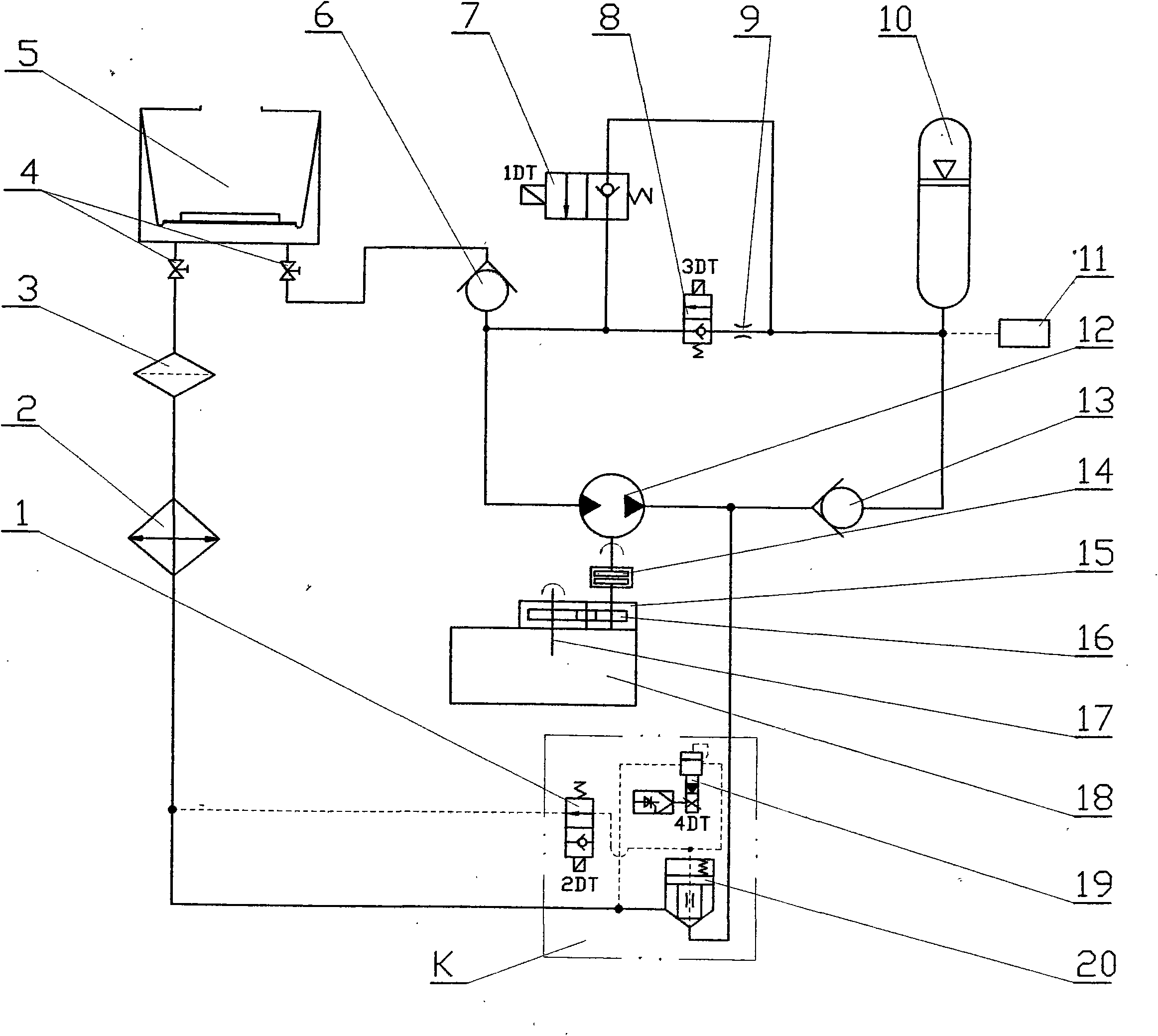

[0018] Now the automobile energy-saving and emission-reducing hydraulic retarder of the present invention will be further described in conjunction with the accompanying drawings.

[0019] See figure 1, the output end of the automobile gearbox 18 is equipped with a sub-box 15 (or a new gearbox that combines them to design one), and the oil pump / oil motor 12 is installed on the sub-box 15 by means of an electromagnetic (or pneumatic, hydraulic) clutch 14 , through a set of gears 16, connected to the output shaft 17 of the automobile gearbox 18, the inlet of the oil pump / oil motor 12 passes through the one-way valve 6 and the stop valve 4 to the diaphragm piston closed oil tank 5; the other way passes through a large two The one-position two-way electromagnetic ball valve 7 is connected to the accumulator 10, which is connected in parallel to the accumulator 10 through a small two-position two-way electromagnetic ball valve 8 and the throttle valve 9; the pressure transmitter 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com