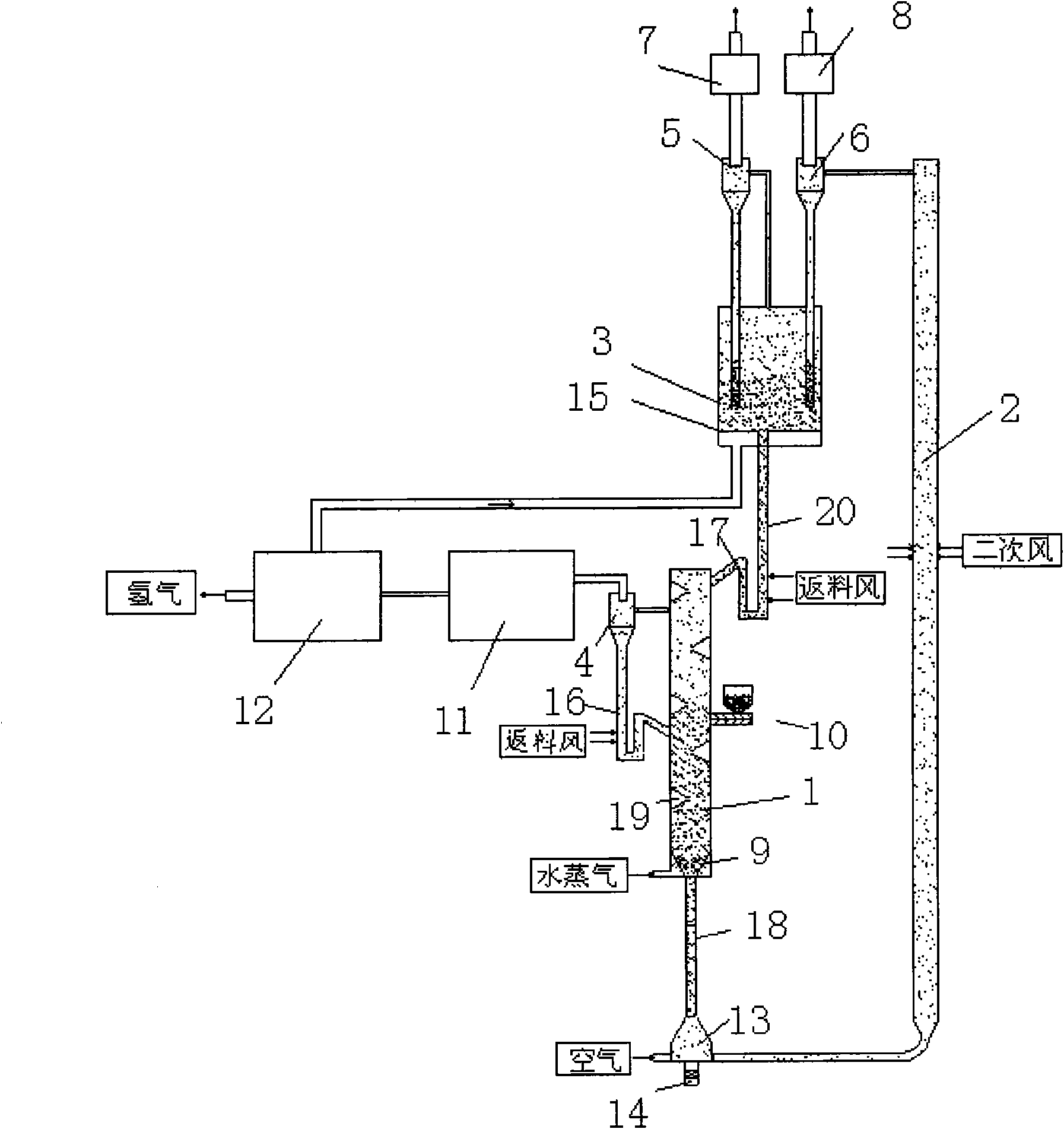

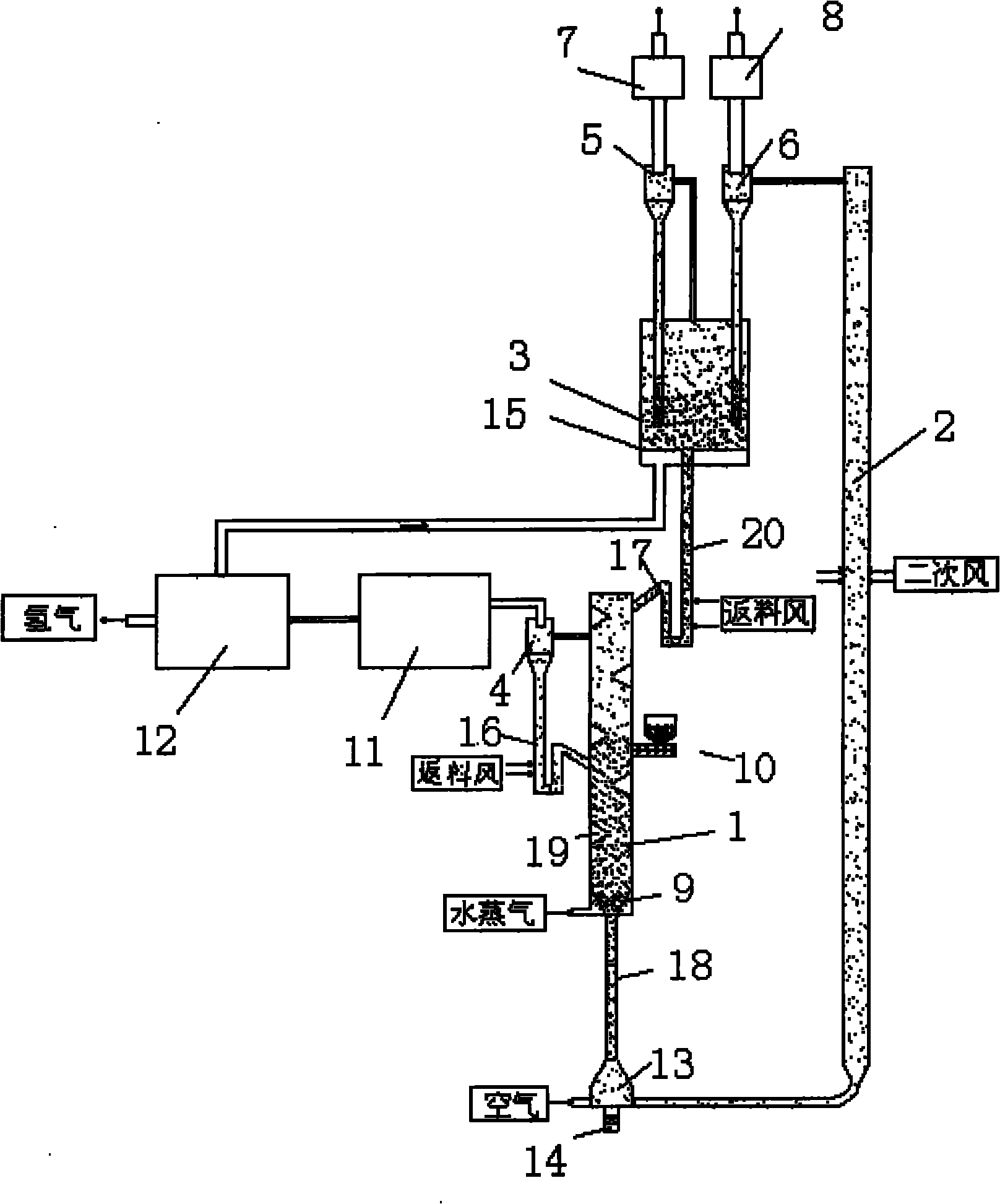

Solid fuel fluidized bed near-zero emission hydrogen generating device

A near-zero emission, solid fuel technology, applied in hydrogen separation, hydrogen production, etc., can solve the problems of complex system control, harsh reactor and reaction conditions, etc., and achieve the effects of energy efficiency, supply, and economical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The broken coal enters the gasification reactor 1 through the feeder 10, and undergoes gasification reaction with the water vapor introduced from the bottom, and the gasification heat is fed from the Fe fuel reactor 2 3 o 4 supply. Fe just entering gasification reactor 1 3 o 4 With a higher temperature, it can also promote the conversion of gasification tar in the upper part. After the gasified gas passes through the first gas-solid separation and transposition 4, it enters the gas purification unit 11 for purification and filtration, and then enters the hydrogen separation unit 12 for separation, so as to produce relatively high-purity hydrogen. And the low-hydrogen combustible gas after separation enters in the fuel reactor 3 and Fe 2 o 3 The reaction produces CO 2 and H 2 O. CO 2 and H 2 The heat carried by O can enter the first waste heat utilization device 7, and then high-purity CO can be obtained after condensation. 2 . And the Fe after the reaction ...

Embodiment 2

[0029] The sawdust enters the gasification reactor 1 through the feeder 10 , and reacts with the water vapor fed from the bottom, and the heat of gasification is provided by the NiO fed into the fuel reactor 2 . The Ni that has just entered the gasification reactor 1 has a relatively high temperature, so it can also promote the conversion of tar in the upper part, and Ni has a certain catalytic effect, which is very beneficial to catalysis. After the gasified gas passes through the first gas-solid separation and transposition 4, it enters the gas purification unit 11 for purification and filtration, and then enters the hydrogen separation unit 12 for separation, so as to produce relatively high-purity hydrogen. The separated low-hydrogen combustible gas enters the fuel reactor 3 through the pipeline to react with NiO to generate CO 2 and H 2 O. CO 2 and H 2 The heat carried by O enters the first waste heat utilization device 7, and then high-purity CO can be obtained after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com