Advanced garbage leachate treatment method

A landfill leachate and advanced treatment technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems that have not yet been reported in research, and achieve good controllability and energy utilization High, the effect of inhibiting the side reaction of oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

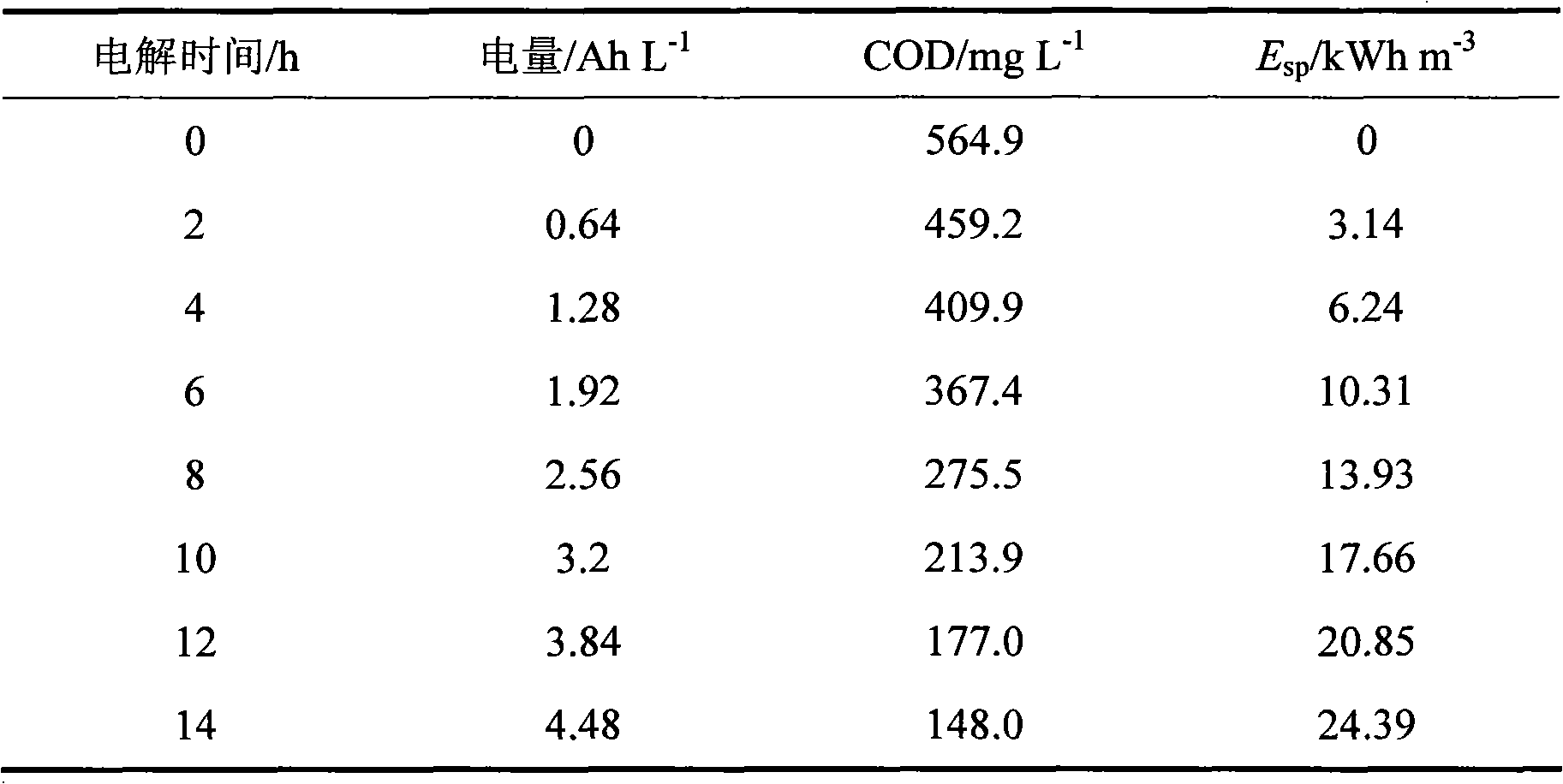

[0024] Using a 20×20mm BDD electrode as the anode, stainless steel of the same size as the cathode, and an electrode spacing of 10mm, electrochemical oxidation advanced treatment of landfill leachate biological water, COD is 564.9mg L -1 around, the current density is 20mAcm -2 . Samples were taken from the reactor every 2 hours to analyze the COD value, and the unit energy consumption was calculated. The experimental results are listed in Table 1. After 8 hours of electrolysis, the passing electricity is 2.56Ah L -1 , the COD of landfill leachate biological effluent was reduced to 275.5mg L -1 , reaching the national secondary emission standard (COD-1 ), the energy consumption is only 13.93kWh m -3 . Table 1 The current density is 20mA cm -2 Biological effluent process of landfill leachate treated by BDD electrode electrochemical oxidation under certain conditions

[0025] Medium COD and E sp changes in

[0026]

Embodiment 2

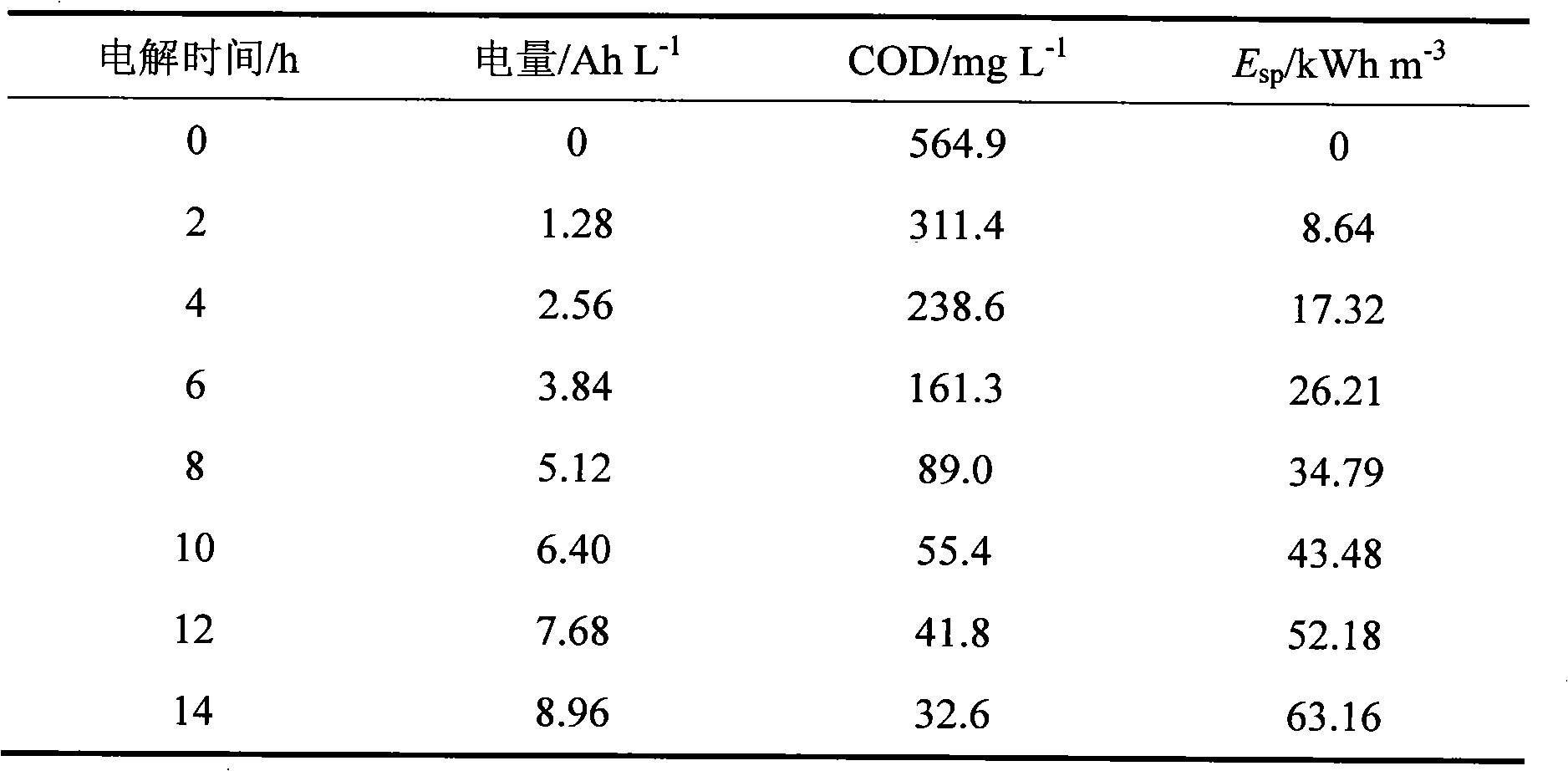

[0028] Using a 20×20mm BDD electrode as the anode, stainless steel of the same size as the cathode, and an electrode spacing of 10mm, electrochemical oxidation advanced treatment of landfill leachate biological water, COD is 564.9mg L -1 around, the current density is 40mAcm -2 . Samples were taken from the reactor every 2 hours to analyze the COD value, and the unit energy consumption was calculated. The experimental results are listed in Table 2. After 8 hours of electrolysis, the passing electricity is 5.12Ah L -1 , the COD of landfill leachate biological effluent was reduced to 89.0mg L -1 , reaching the national first-level emission standard (COD-1 ), while the energy consumption is only 34.79kWh m -3 . Table 2 The current density is 40mA cm -2 Biological effluent process of landfill leachate treated by BDD electrode electrochemical oxidation under certain conditions

[0029] Medium COD and E sp changes in

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com