Method for treatment of turbid circulating water by steelmaking slag

A technology for turbid circulating water and treatment methods, applied in water/sludge/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Problems such as difficulty in layout layout, to achieve the effect of convenient management and operation, ensuring the effect, and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

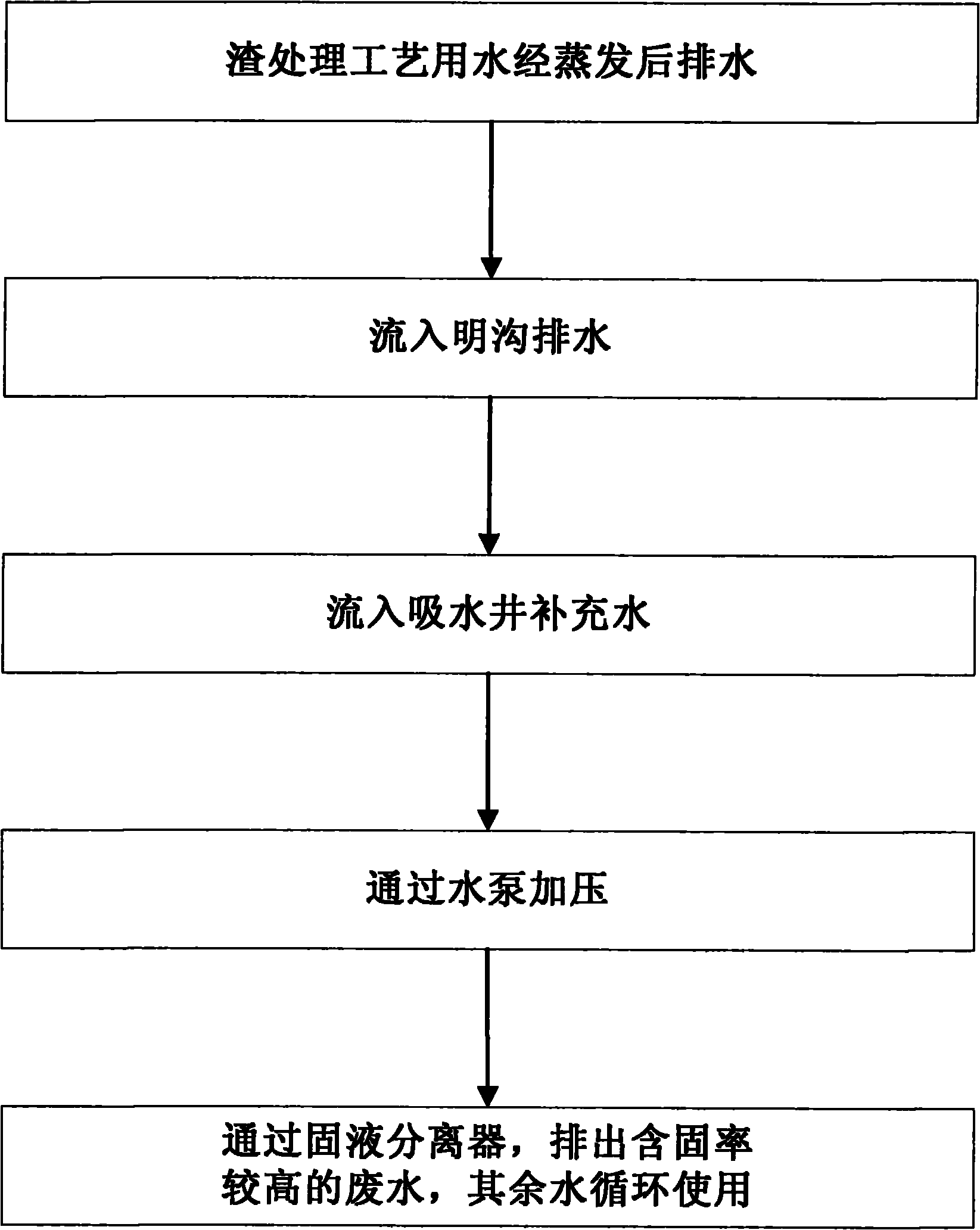

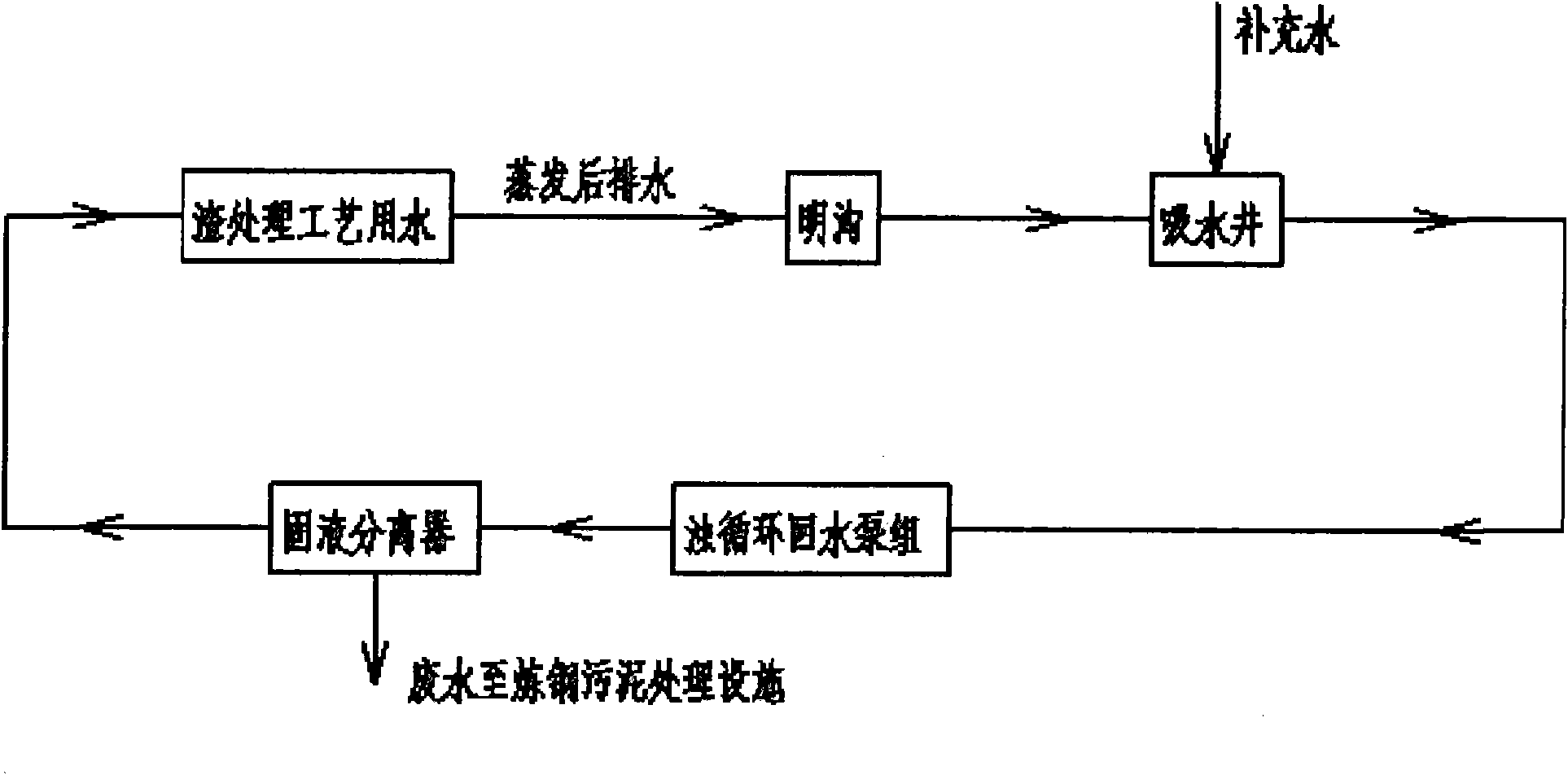

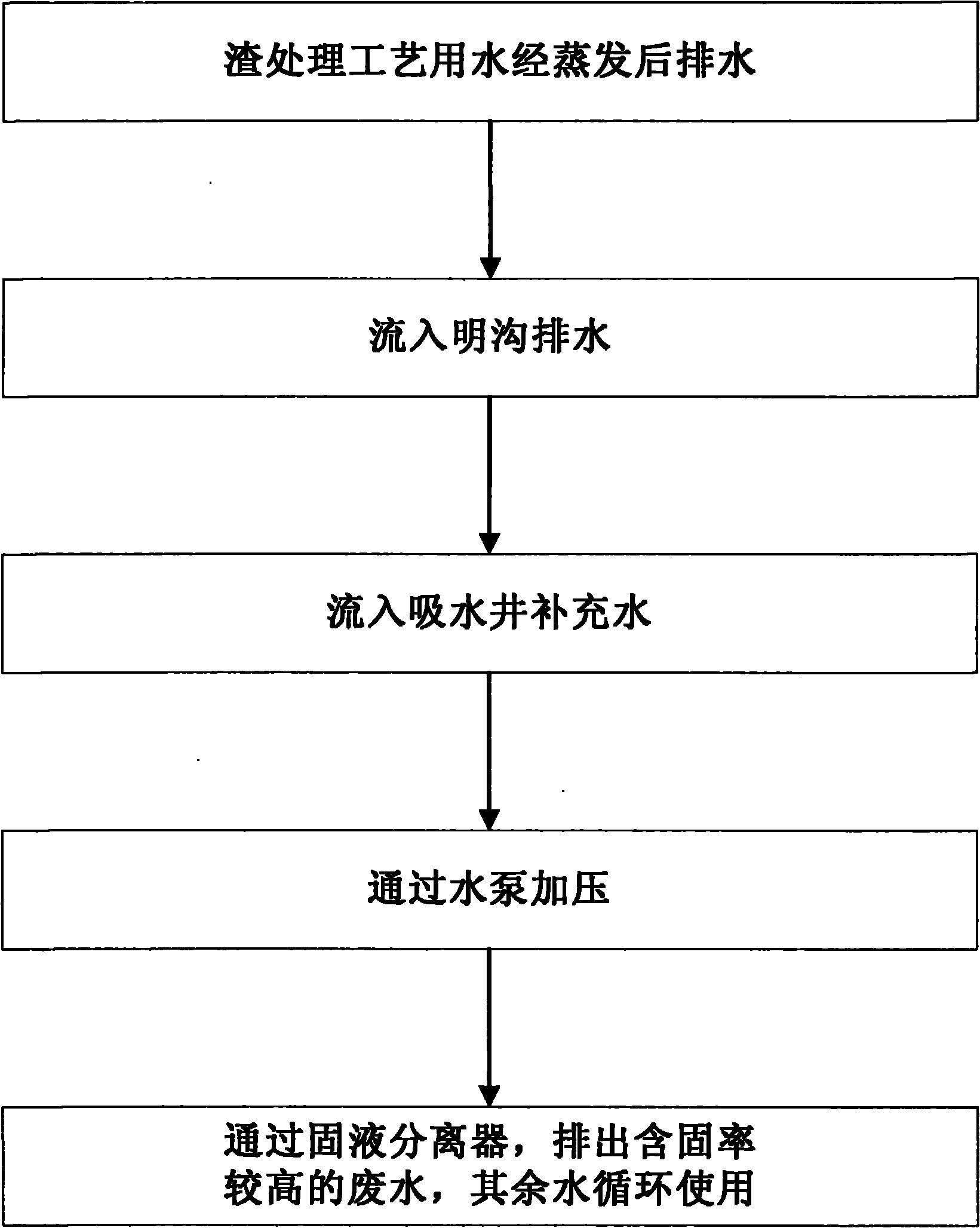

[0031] Such as figure 1 with figure 2 As shown, the slag treatment process water is evaporated and drained, then flows into the open ditch for drainage, flows into the water absorption well to replenish water, then pressurizes through the water pump, and finally passes through the solid-liquid separator to discharge the wastewater with high solid content, and the rest of the water is recycled.

[0032] This process uses a solid-liquid separator to replace the advection sedimentation tank of the traditional process. The solid-liquid separator is based on the principle of centrifugal separation and is used to separate the precipitated solids in the liquid. The accelerated motion inside the solid-liquid separator generates a high-speed rotating vortex, which efficiently separates the solid impurities in the liquid. At present, the new solid-liquid separator can separate solid particles with a specific gravity greater than liquid from 3 μm to 9 mm. The turbid circulating water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com