Acrylic resin metallic brilliant baking paint

An acrylic resin, metal flash technology, applied in the direction of coating, can solve the problems of paint film thickness, paint film breakdown, poor spray decoration effect, etc., to achieve excellent paint film performance, high paint rate, uniform appearance of paint film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of acrylic resin metal flash baking varnish of the present invention is as follows:

[0017] 1) Disperse the aluminum-silver paste: weigh the aluminum-silver paste in the dispersion tank, accurately weigh the organic solvent in another bucket, stir well to make a mixed solvent, and add the mixed solvent to the dispersion tank containing the aluminum-silver paste, Use a high-speed disperser to disperse for 20-40 minutes at a speed of 1-8m / s, and set aside;

[0018] 2) Add the metal pigment alignment aid into the organic solvent, stir, dissolve, and set aside;

[0019] 3) Paint preparation: Weigh and put acrylic resin and amino resin in order in the paint mixing tank, turn on the high-speed disperser and adjust the speed to 1-8m / s, and add metal pigment alignment aids, leveling agents, For the remaining materials such as conductive additives, after adding each material, disperse for 20-60 minutes.

[0020] 4) Paint preparation: Add the aluminum-si...

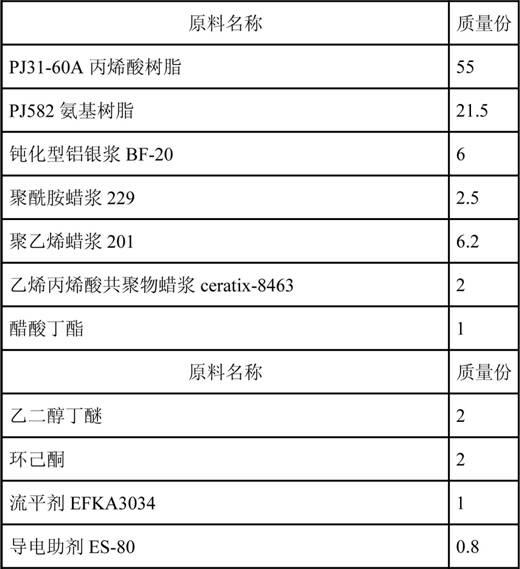

Embodiment 1

[0030] The composition of the acrylic resin metallic glitter baking varnish is as follows:

[0031]

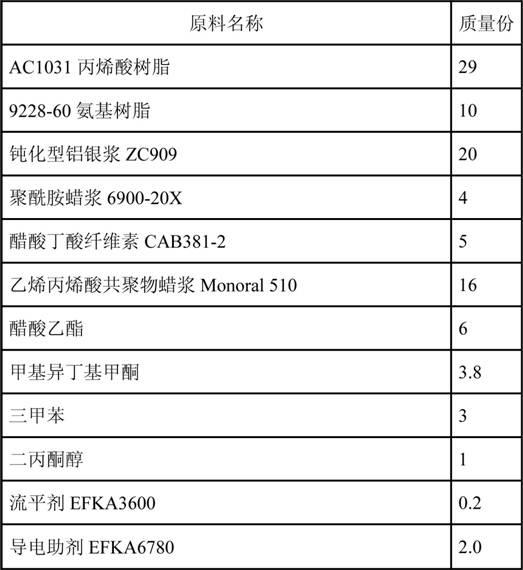

Embodiment 2

[0033] The composition of the acrylic resin metallic glitter baking varnish is as follows:

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com