Coal water slurry gasification furnace for gasifying coal water slurry

A technology of coal water slurry and gasifier, which is applied in the field of coal gasification, can solve the problems of shortening the service life of the gasifier, limiting the atomization effect of the Texaco nozzle, increasing the maintenance cost, etc., to prolong the life of the nozzle and The production operation cycle, the reduction of water in the quenching chamber, and the effect of reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Specific embodiments of the present invention are provided below. It should be understood by those skilled in the art that the examples herein are for illustrative purposes only and should not be construed as limiting the scope of the invention defined by the claims in any way.

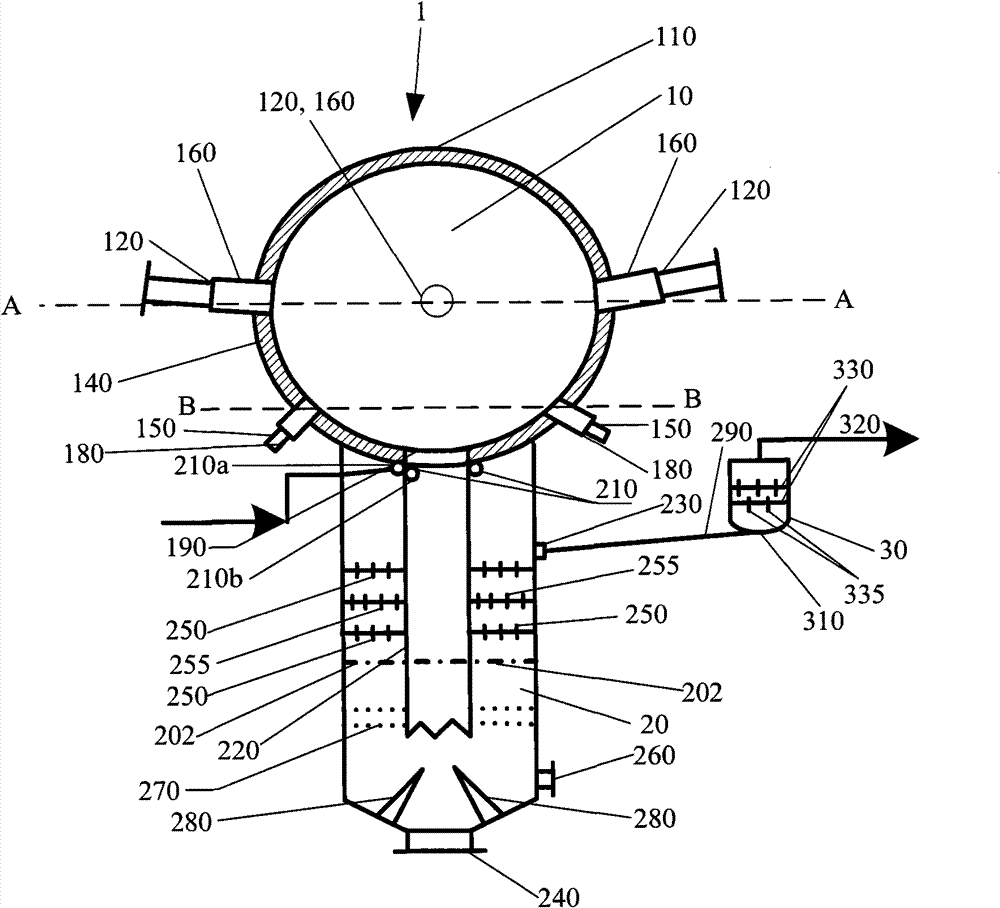

[0063] In a specific embodiment of the present invention, a novel multi-nozzle coal-water slurry gasifier for coal-water slurry is provided, comprising:

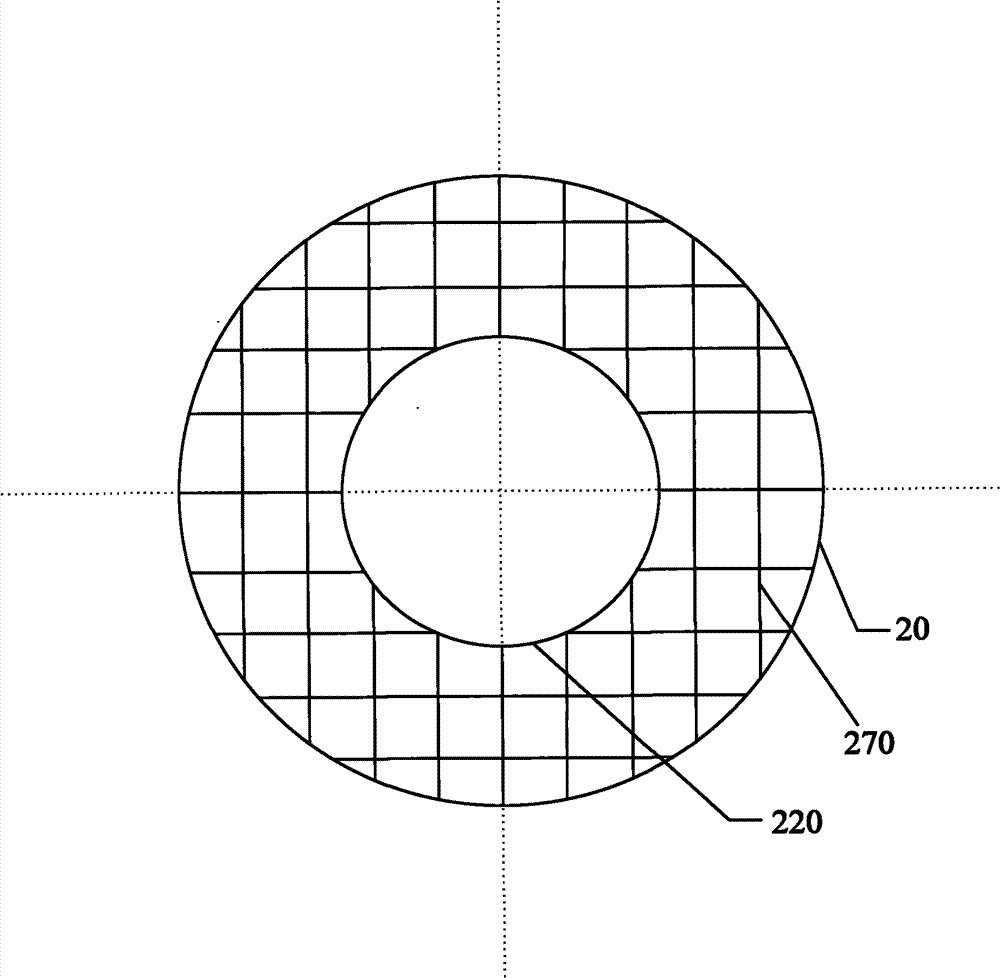

[0064] The combustion chamber 10 and the cooling chamber 20,

[0065] It is characterized in that the combustion chamber 10 further includes:

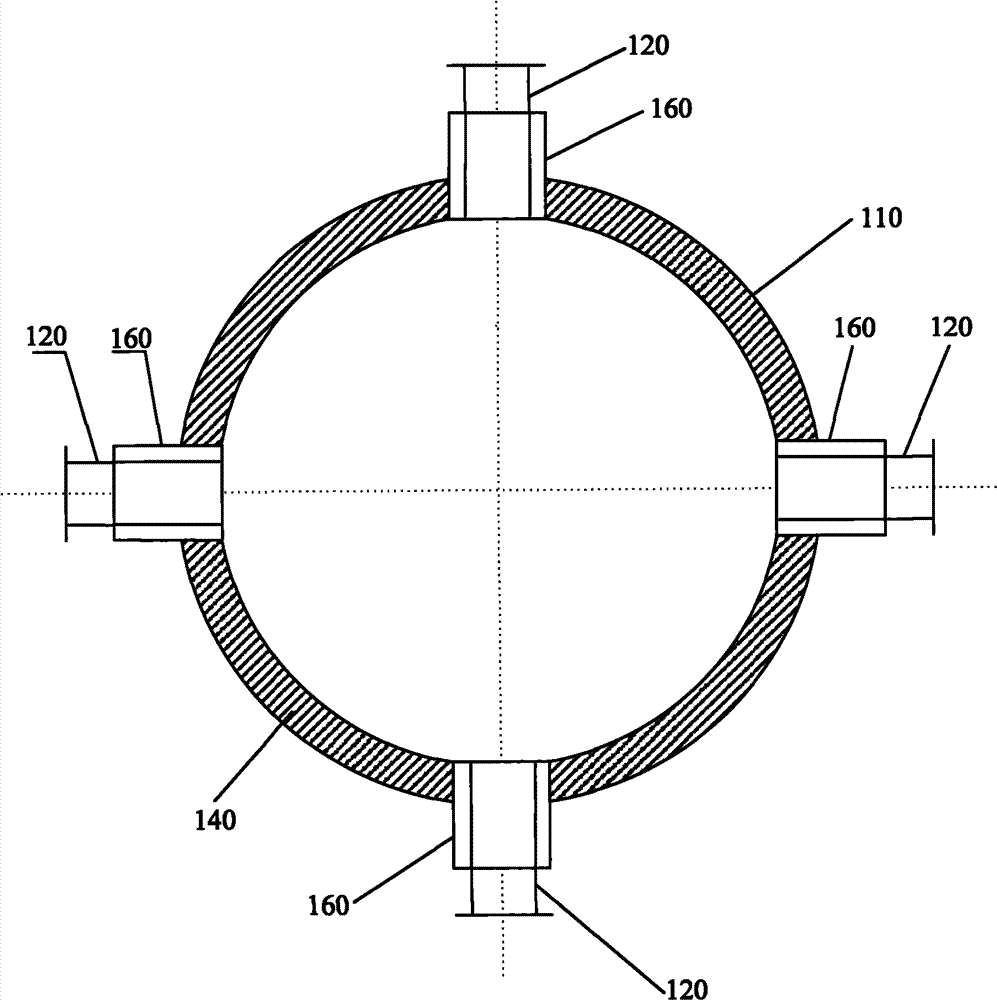

[0066] A quasi-ellipsoidal wide-diameter combustion chamber housing 110,

[0067] At least two coal-water slurry and oxygen three-channel process nozzle chambers 160 are symmetrically arranged at the wide diameter A-A of the combustion chamber housing 110, and are slightly inclined downward.

[0068] At least two coal-water slurry and oxygen three-runner nozzles 120 are detachably installed in each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com