Ultrasonic-assisted extraction method for tung oil

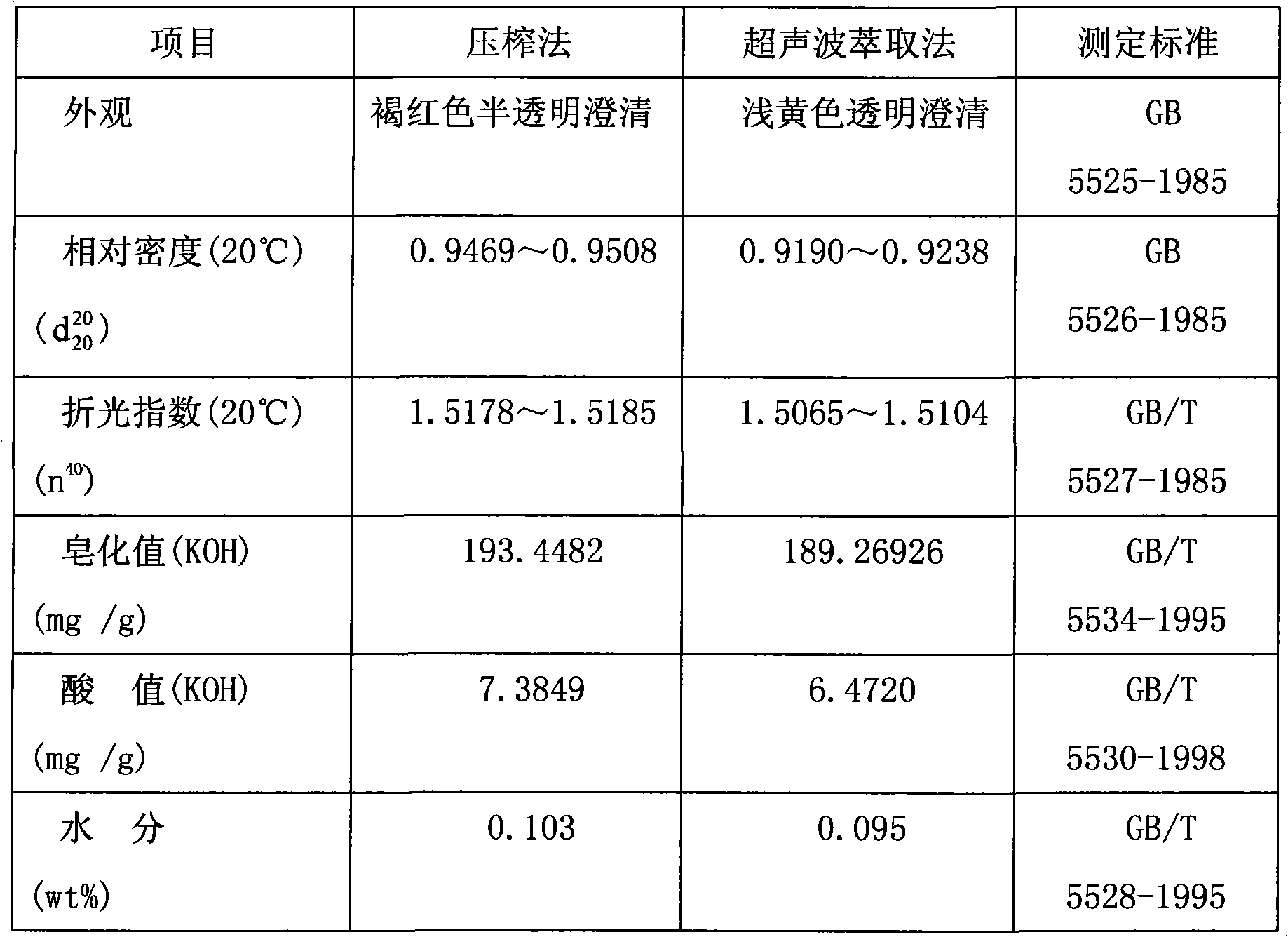

An auxiliary extraction and ultrasonic technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of no application of ultrasonic waves, mature and standardized technology for extracting tung oil, and achieve bright color, less impurities, and low extraction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a detailed description in conjunction with the embodiments:

[0029] 1. Experiment of extracting tung oil

[0030] ①Select mature Tung tree fruits and get 6.04g Tung tree seeds by removing the husk and seed coat;

[0031] ② Dry the Tung tree seeds in a drying box at 120°C for 1.5 to 2 hours. The quality difference before and after drying is ±0.5%. After cooling, crushed to obtain Tung oil seed powder;

[0032] ③Mix the tung oil seed powder and ethyl acetate at a ratio of 1g:10ml and place them in a triangular flask. After sealing, place them at 40°C and continue to act on ultrasonic waves for 1.5 hours; filter the mixture with suction to remove the solid residue oil dregs, and collect the filtrate;

[0033] ④ Carry out the oil meal once according to step ③, and combine the filtrate obtained with step ③;

[0034] ⑤ The filtrate was distilled under reduced pressure through a rotary evaporator at 40° C. and a negative pressure of 0.06-0.08 Mp to obtain 3.92 g of tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com