Permanently leakage-proof roof leakage repairing and greening technology

A leakage repairing and technical technology, which is applied in the direction of roofing, roof covering, soilless cultivation, etc., can solve the problems that roof leakage has not been completely solved, there is no plant protection layer, and leakage at repairing parts, so as to reduce the temperature difference and avoid wind blowing The effects of rain and beautification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

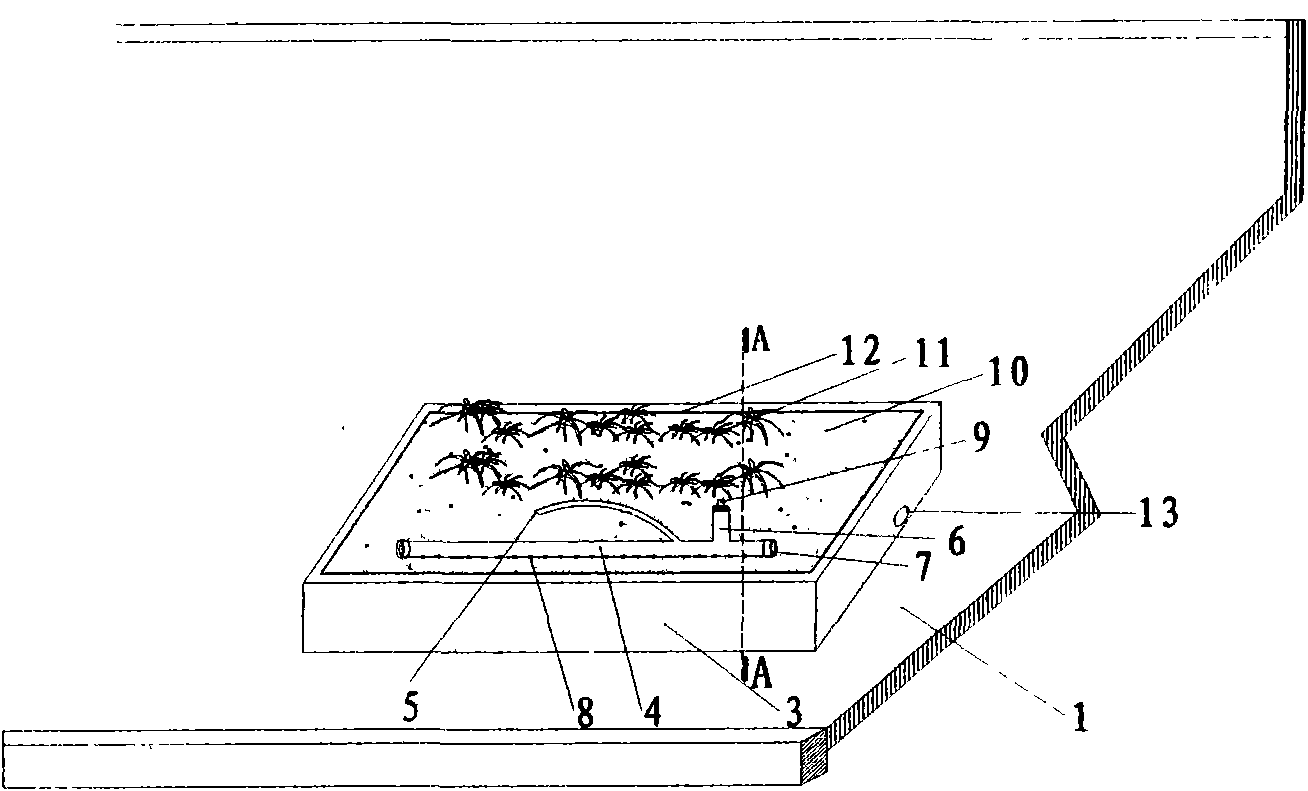

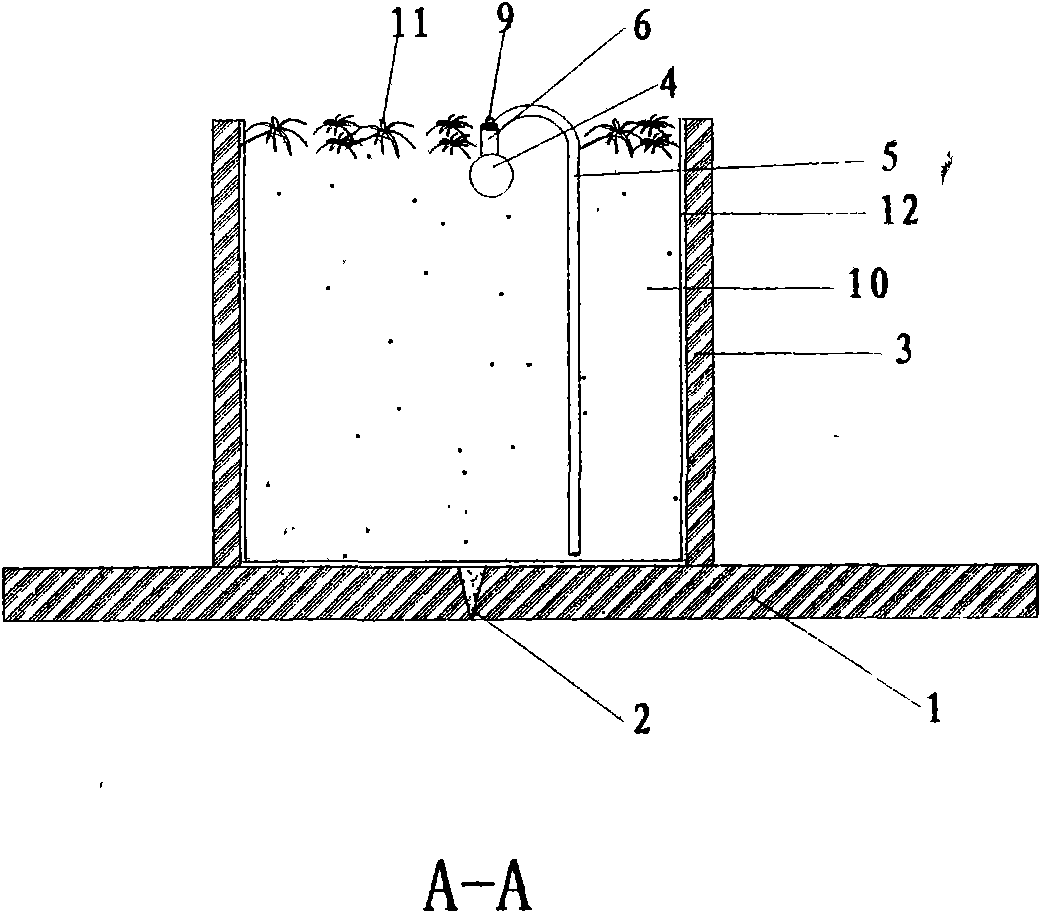

[0011] The present invention comprises a plant cultivation tank (3), which is made of bricks or concrete cast-in-situ or made of plastic boards. The cultivation tank (3) is placed on the roof (1) or the leak-remediation position (2), and the leak-remediation material is of the prior art, preferably adds rubber or novel waterproof adhesive with asphalt. The bottom of the cultivation tank (3) and the inwall have a root layer (12) (also a small amount of nutrient solution storage layer), and the root layer (12) is done with a plastic film. There is a drainage hole (13) on the bottom edge of one side of the cultivation groove (3). Drain holes (13) penetrate the root layer (12). Its position is slightly higher than the cultivation groove (3) bottom. The rainwater falling into the cultivation tank (3) can be discharged without causing a small amount of nutrient solution at the bottom of the cultivation tank (3) to flow away. The cavity of the root-separating layer (12) is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com