Exhaust gas recirculation system for spark ignition engine

A technology of exhaust gas recirculation and spark ignition, which is applied in the direction of exhaust gas recirculation, engine components, combustion engines, etc., can solve the problems of complex system, high cost, complexity, etc., reduce component damage, large manufacturing errors, and ensure reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

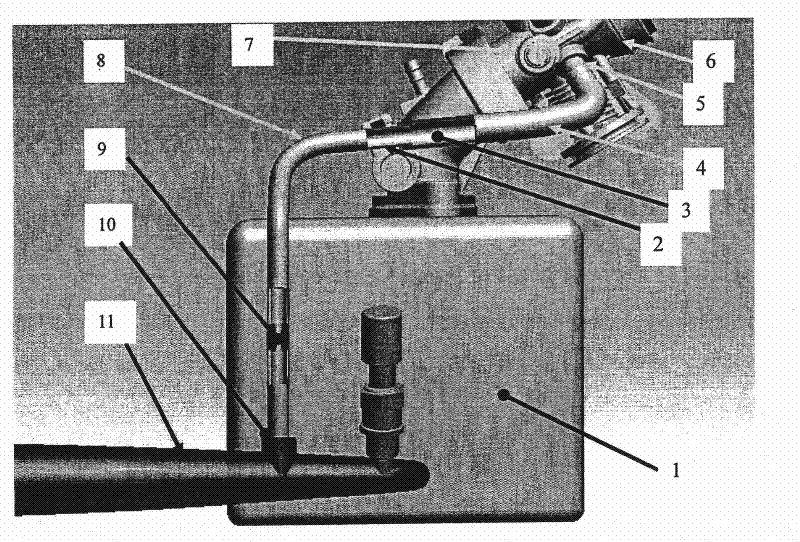

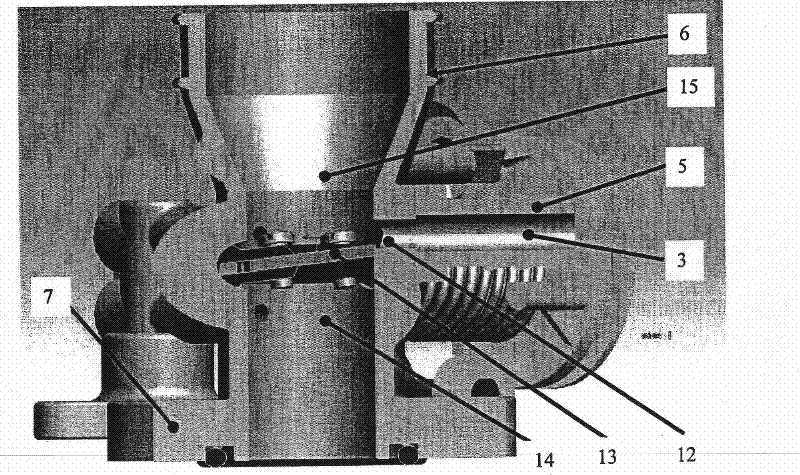

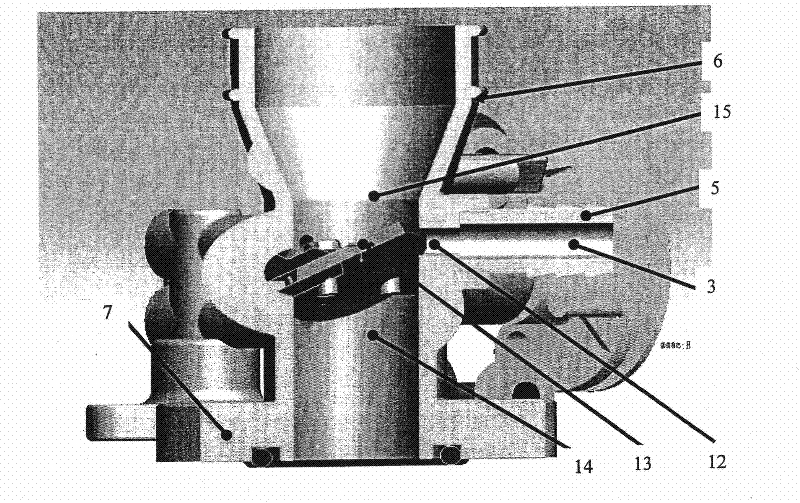

[0027] exist figure 1In the shown first embodiment of the present invention, the engine is a 100-125mL displacement engine used by a bent beam motorcycle, including engine body 1, intake throttle body 7, exhaust pipe 11, EGR The guide pipe (8, 4) is provided with the EGR joint 5 on the throttle body 7, and the EGR joint 10 is provided on the exhaust pipe 11, and the EGR guide pipe 8 is a metal pipe that can withstand the high temperature of the exhaust gas. The EGR guide pipe 4 is a rubber hose, and the two are connected through the pipe joint 2 . At one end of the EGR guide pipe 8 close to the exhaust pipe 11, a throttling hole 9 is provided with a throttling hole diameter of 2.5-3.5 mm. The length from the throttle hole 9 to the part of the EGR guide pipe of the pipe joint 2 is about 90mm, so as to ensure that the temperature of the EGR guide pipe 4 will not be higher than the heat resistance limit of the rubber hose. The flow area of the EGR guide hole 3 formed inside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com