Focusing lens group and laser processing applied optics system

A technology of laser processing and applied optics, applied in optics, optical components, laser welding equipment, etc., can solve problems such as scribing work trouble, chromatic aberration, and inability to monitor in real time, so as to eliminate imaging interference and ensure accuracy and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

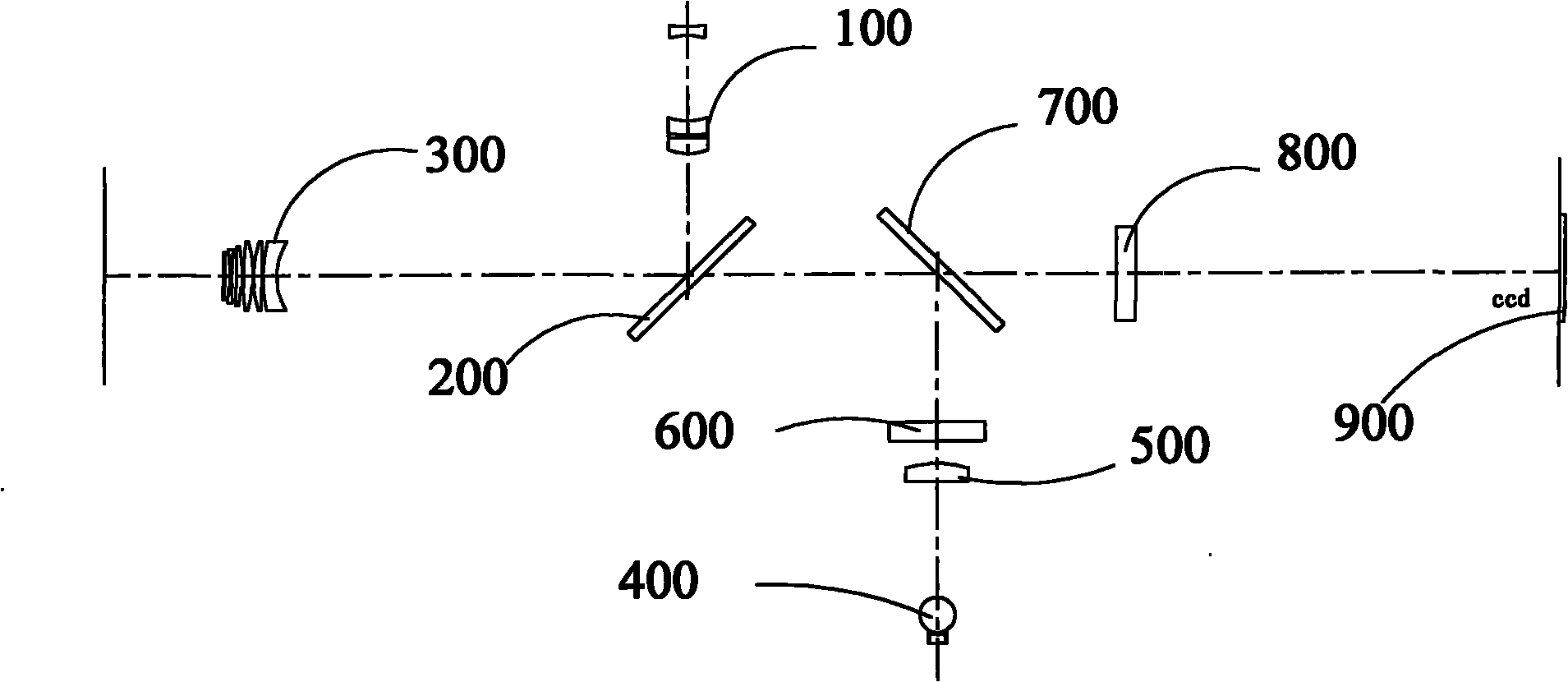

[0039] figure 1 It is a structural schematic diagram of an optical system for laser processing application in an embodiment. In this embodiment, the laser application optical system includes a laser processing system and a laser monitoring system.

[0040]The laser processing system is used to process the workpiece to be processed, and it includes: a beam expander lens group 100 , a first filter mirror 200 and a focusing lens group 300 placed sequentially along the optical axis from the laser exit end.

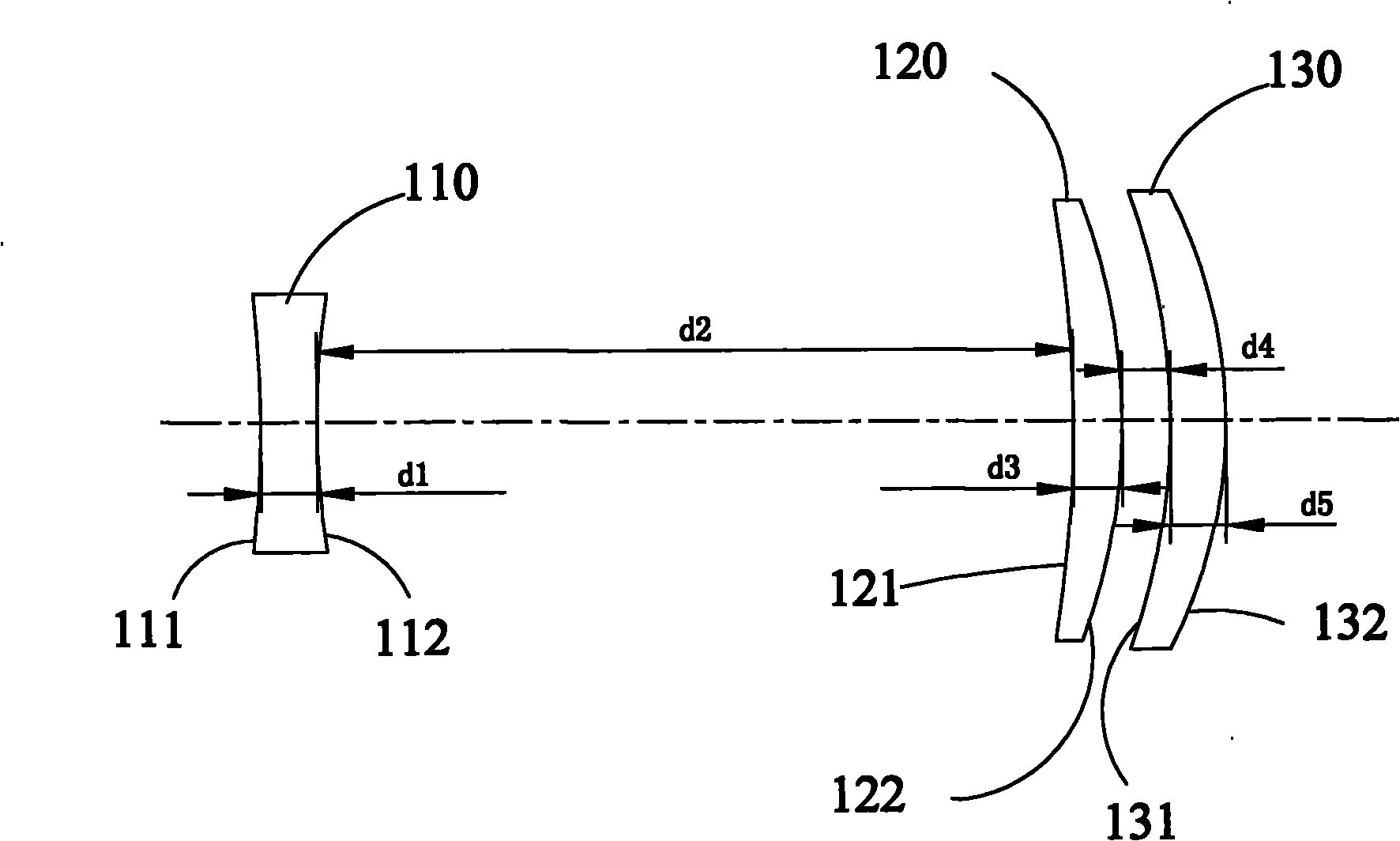

[0041] figure 2 It is a schematic diagram of the structure of the beam expander group in one embodiment. In this embodiment, the beam expander lens group 100 performs beam expansion and shaping on the laser beam, which includes the first lens 110 of the beam expander lens group, the second lens 120 of the beam expander lens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com