Novel manufacturing process of touch screen

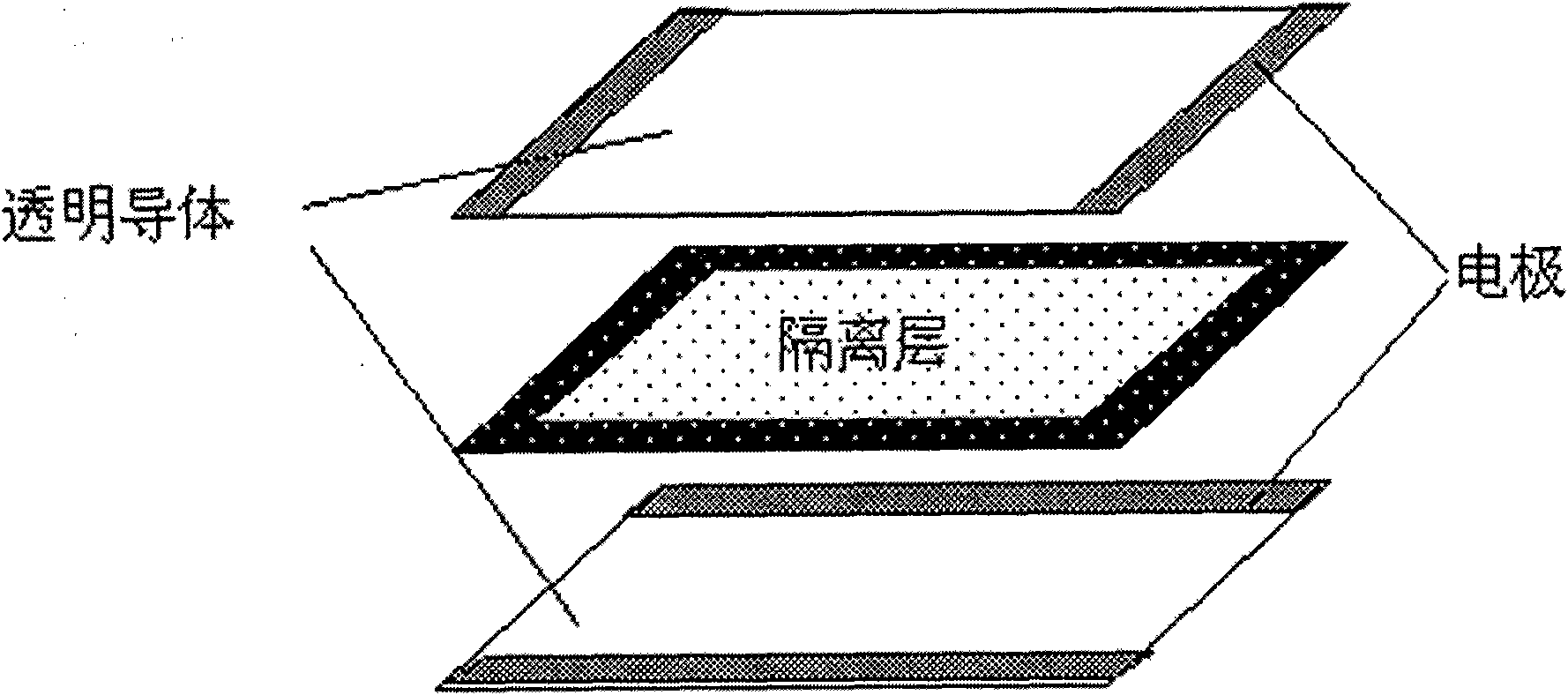

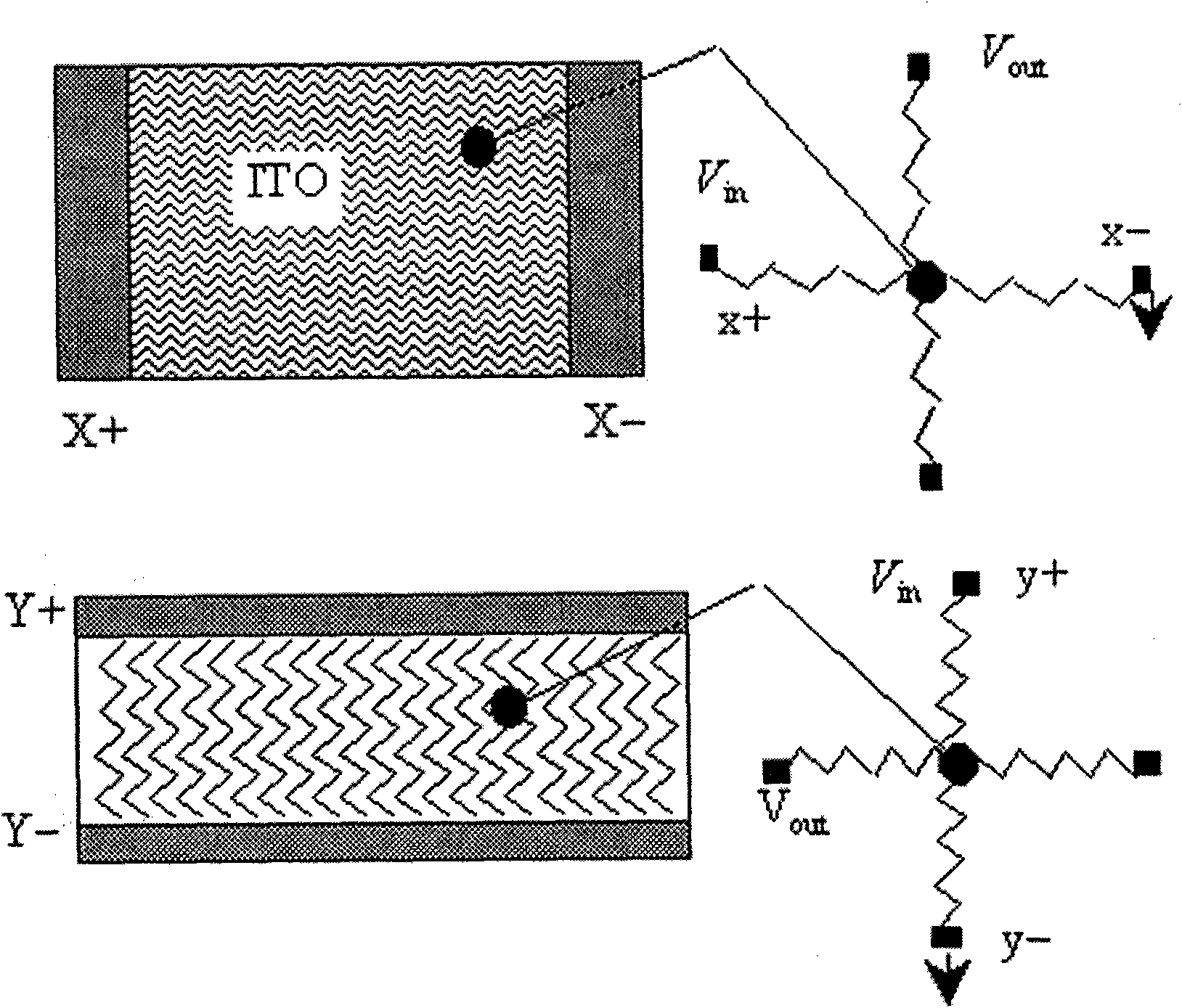

A manufacturing process, touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing and other directions, can solve the problems of many processes, increased cost, ITO layer damage, etc., to achieve simple manufacturing process, time saving, Source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

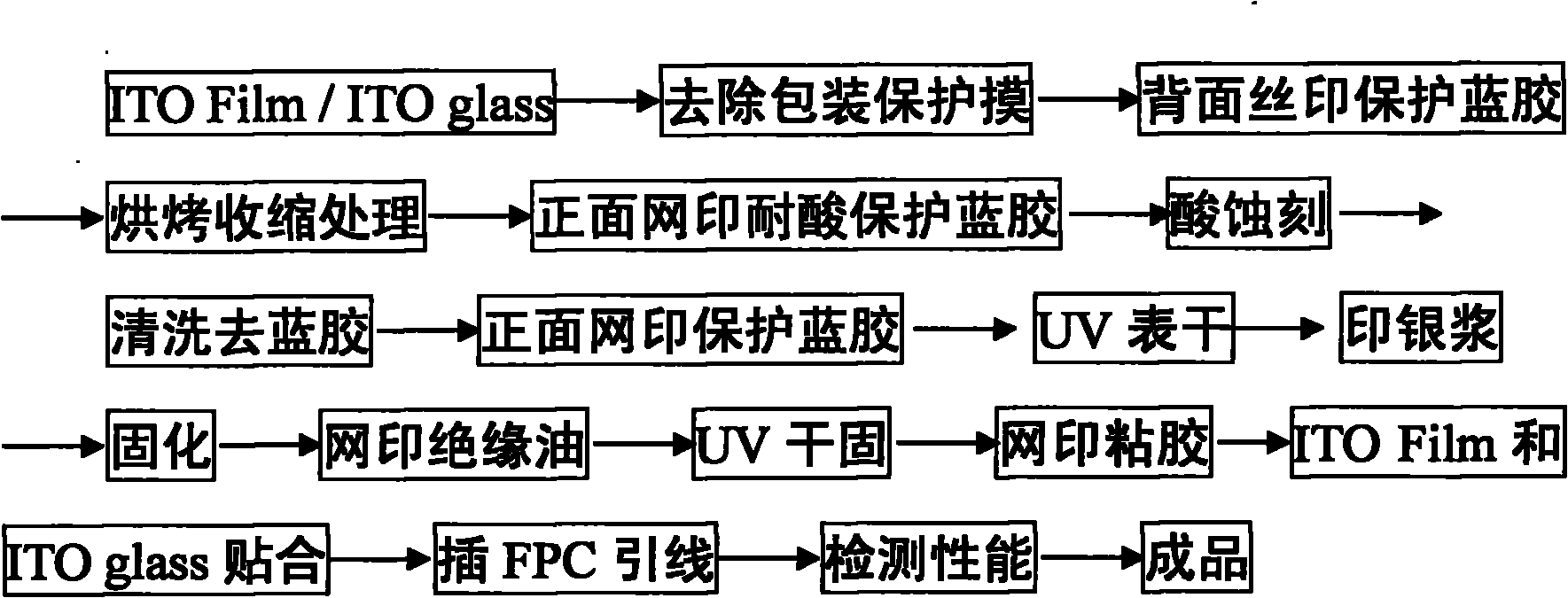

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0043] A new manufacturing process of touch screen, such as Figure 4 ,

[0044] Including the following steps:

[0045] Step 1, choose PET and glass, surface treatment: choose PET polyester sheet and glass substrate; then do hard coating on PET, do silica coating on glass, in order to be suitable for the surface before the transparent conductive layer Prepare;

[0046] Step 2, screen printing transparent conductive ink: then use a fine screen printing machine to print the transparent conductive ink on the above-mentioned PET and glass after surface treatment;

[0047] Step 3, curing: the corresponding PET material is baked at 130 degrees for 40 minutes, and the glass material is baked at 150 degrees for 30 minutes, and the two materials are cured respectively;

[0048] Step 4, screen printing silver paste: then add the cured PET and glass to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com