Filter stick for cigarettes and preparation method thereof

A technology for filter rods and cigarettes, applied to the field of filter rods for cigarettes and their preparation, can solve the problems of reducing the smoking quality of cigarettes, high cost of materials such as precious metals, and achieve the effects of low price, easy acquisition, and increased aroma volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

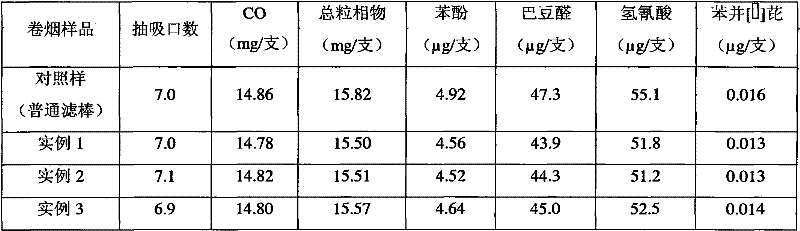

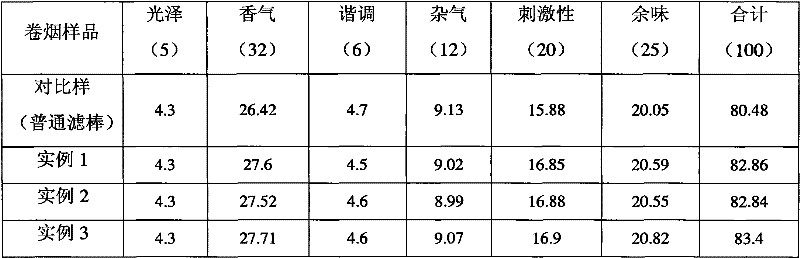

Examples

Embodiment 1

[0027] Get 5 kg of naturally dried Shegan rhizomes and dry them at 60°C until the water content is 10%. Use a pulverizer to pulverize separately, pass through a 60-mesh sieve after pulverization, and obtain dry powder particles. Take Guangdong China Tobacco A brand tobacco shredded tobacco, and dry it at 60°C until the moisture content is 10%. Use a pulverizer to pulverize separately, and pass through a 60-mesh sieve after pulverization to obtain tobacco powder particles. The above two kinds of powder particles were uniformly mixed at a ratio of 4:6, and then subjected to moisture regain treatment to make the water content of the mixture particles 30%, and stored for 12 hours. After regaining moisture, the mixture granules are dehydrated, and dried at low temperature (60° C.) until the water content is 6% to obtain the mixture granules of the composite filter rod for cigarettes.

[0028] The particles of the mixture were evenly added to the diacetate tows, alternating with t...

Embodiment 2

[0033] Get 5 kg of naturally dried Shegan rhizomes and dry them at 60°C until the water content is 10%. Use a pulverizer to pulverize separately, pass through a 60-mesh sieve after pulverization, and obtain dry powder particles. Take Guangdong China Tobacco A brand tobacco shredded tobacco, and dry it at 60°C until the moisture content is 10%. Use a pulverizer to pulverize separately, and pass through a 60-mesh sieve after pulverization to obtain tobacco powder particles. The above two kinds of powder particles were uniformly mixed at a ratio of 3:7, and then subjected to moisture regain treatment to make the water content of the mixture particles 30%, and stored for 12 hours. After regaining moisture, the mixture granules are dehydrated, and dried at low temperature (60° C.) until the water content is 8% to obtain the mixture granules of the composite filter rod for cigarettes.

[0034] The particles of the mixture were evenly added to the diacetate tows, alternating with t...

Embodiment 3

[0039]Get 5 kg of naturally dried Shegan rhizomes and dry them at 60°C until the water content is 10%. Use a pulverizer to pulverize separately, pass through a 60-mesh sieve after pulverization, and obtain dry powder particles. Take Guangdong China Tobacco A brand tobacco shredded tobacco, and dry it at 60°C until the moisture content is 10%. Use a pulverizer to pulverize separately, and pass through a 60-mesh sieve after pulverization to obtain tobacco powder particles. The above two kinds of powder particles were uniformly mixed at a ratio of 3:7, and then subjected to moisture regain treatment to make the water content of the mixture particles 30%, and stored for 12 hours. After regaining moisture, the mixture granules are dehydrated, and dried at low temperature (60° C.) until the water content is 8% to obtain the mixture granules of the composite filter rod for cigarettes.

[0040] The particles of the mixture were evenly added to the diacetate tows, alternating with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com