Barometric slag-water separation system

A slag-water separation, air pressure technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., to achieve the effect of good effect, low cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

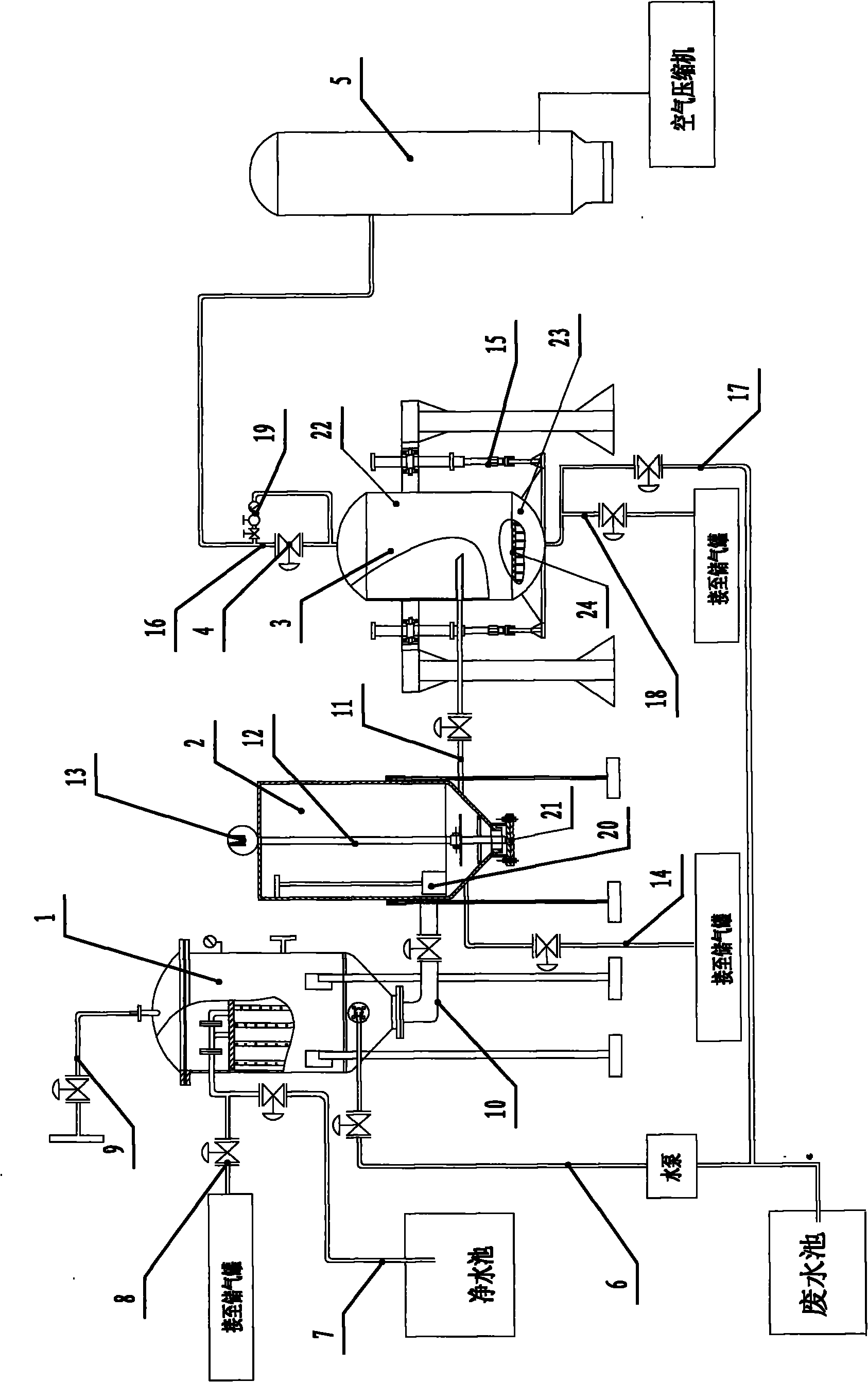

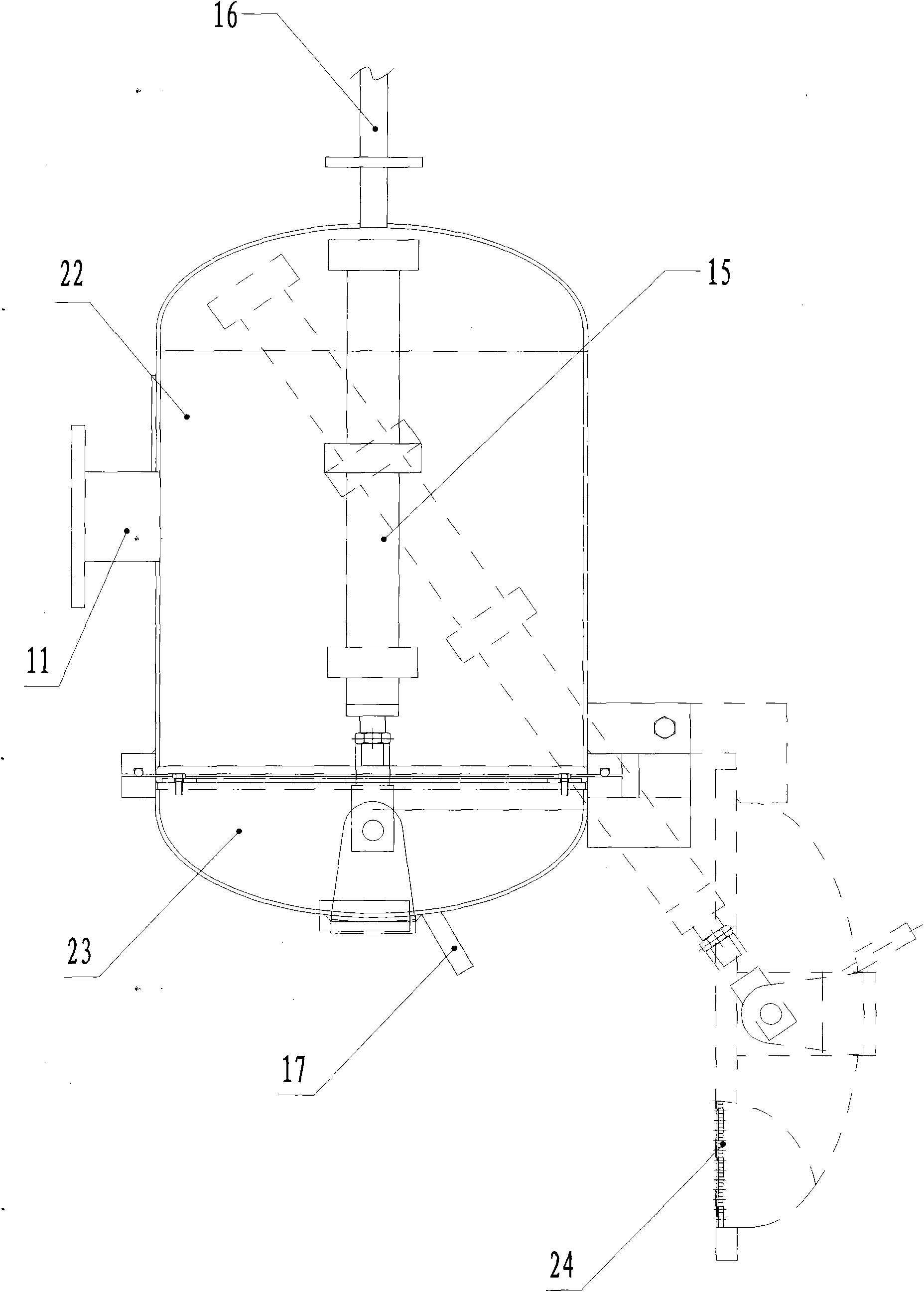

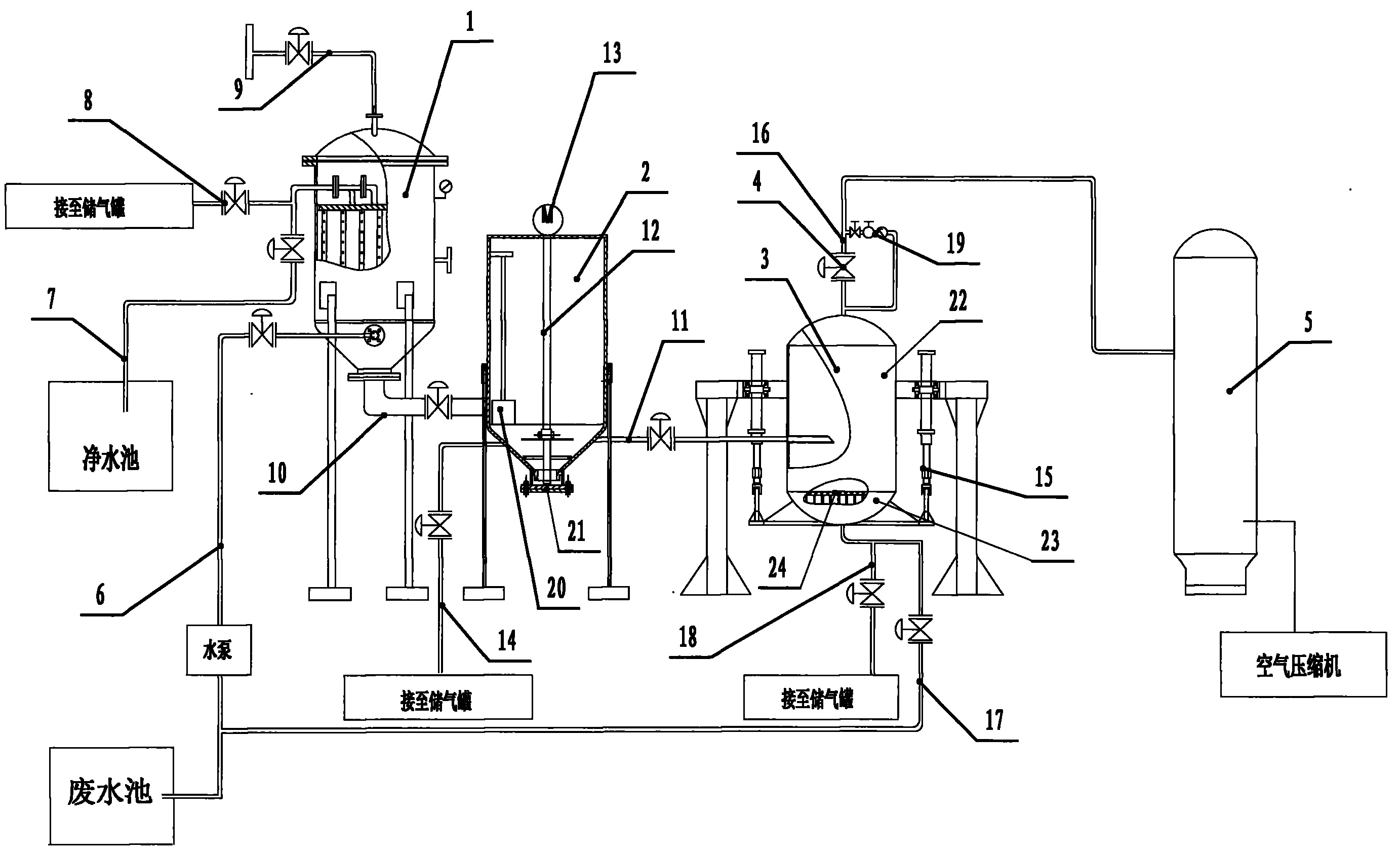

[0018] A pneumatic slag water separation system of the present invention such as figure 1 As shown, it is mainly composed of a filter 1, a buffer tank 2 and a desiccator 3; the filter 1 is in the shape of a sealed and hollow barrel, the top of which is provided with an exhaust pipe 9 communicating with the outside, and the upper part is provided with a discharge clean water The clean water pipe 7, the lower part is provided with a waste water pipe 6 for introducing waste water, and the bottom is provided with a slag discharge pipe 10 connected to the buffer tank 2. The above waste water pipe 6 is connected to the waste water discharge port through a water pump. In the inner cavity of the filter 1 Vertically suspend a plurality of thin tubular filter tubes, the side walls of the filter tubes are provided with a plurality of through holes, the filter tubes are filled with filter bodies, the upper ends of the filter tubes communicate with the water purification pipe 7, and the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com