Preparation method, product and application of iron-loaded biochar

A biochar, iron-loaded technology, applied in chemical instruments and methods, catalyst activation/preparation, water pollutants, etc., can solve the problems of slow degradation of organic matter, difficult recycling of biochar materials, low degradation rate, etc. The effect of activation, short pyrolysis time, and efficient catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Clean and shred the wheat straw, place it in a blast drying oven, dry it at 105°C for 10 hours, crush it, and pass it through a 100-mesh sieve for later use;

[0036] (2) The biomass obtained by sieving 3g step (1), 5.56g FeSO 4 ·7H 2 O and 3.54g of ascorbic acid were put into a polytetrafluoroethylene-lined bottle of an autoclave, mixed with water, heated at 160°C for 12h, cooled naturally, and vacuum-dried at 80°C for 24h to obtain material A;

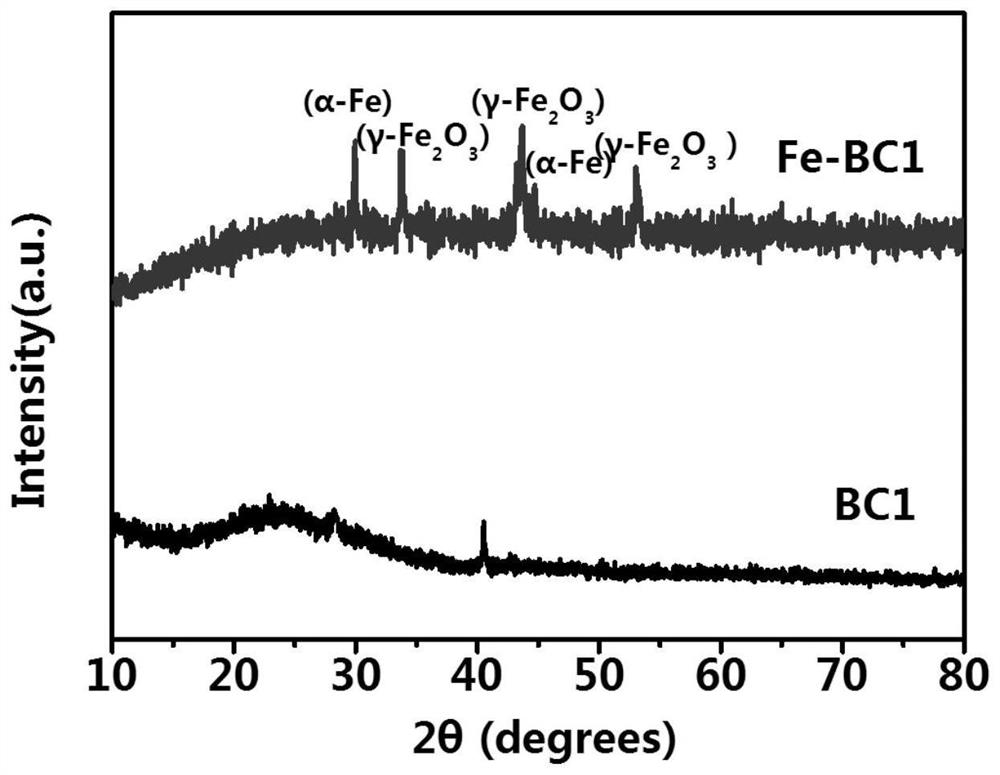

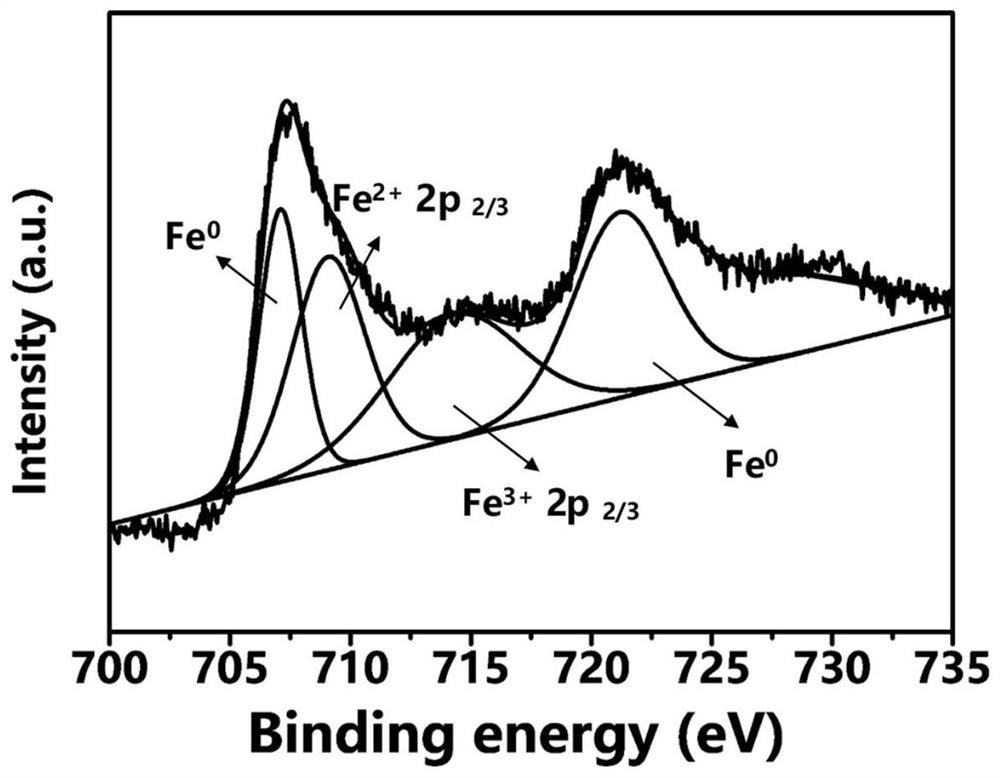

[0037] (3) Material A is placed in a quartz boat, and in N 2 Under the atmosphere, place it in a tube furnace, heat up to 700°C at a rate of 10°C / min for pyrolysis for 120 minutes, and then naturally cool down to room temperature to obtain iron-loaded biochar, which is designated as Fe-BC1.

Embodiment 2

[0039] (1) Wash and shred the rice straw, place it in a blast drying oven, dry it at 100°C for 9 hours, crush it, and pass it through a 200-mesh sieve for later use;

[0040] (2) The biomass obtained by sieving 3g step (1), 2.5g FeSO 4 ·7H 2 O, 2.0g FeCl 3 ·6H 2 0 and 7.1 g of ascorbic acid were put into a polytetrafluoroethylene-lined bottle of an autoclave, mixed with water, heated at 120° C. for 24 hours, cooled naturally, and vacuum-dried at 50° C. for 16 hours to obtain material A;

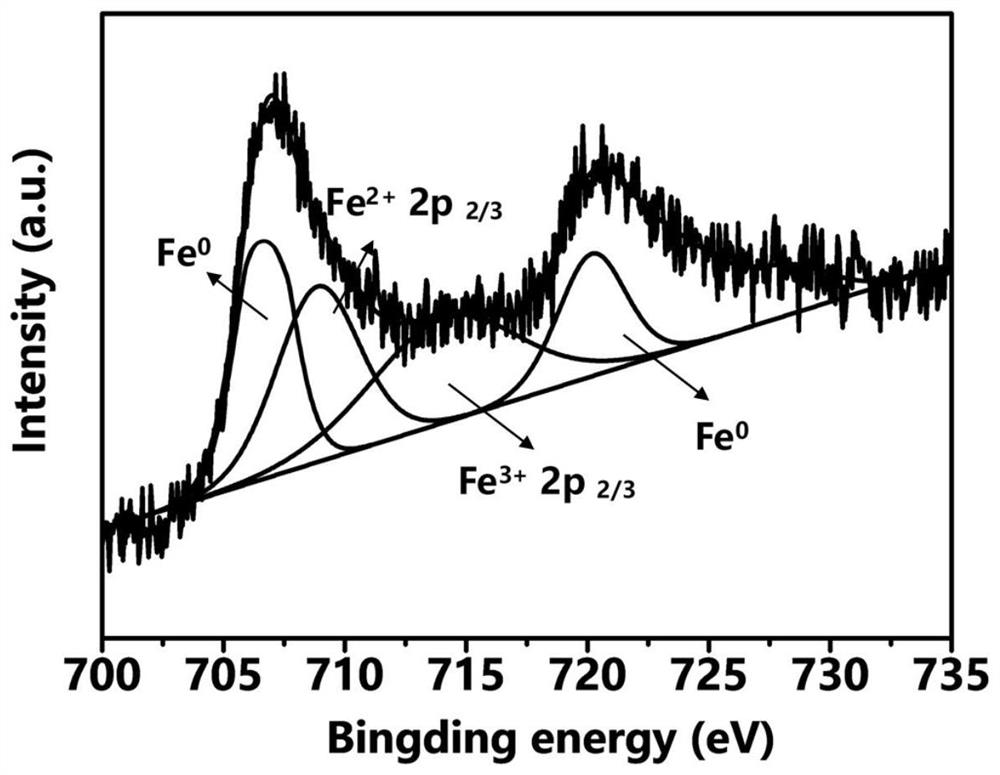

[0041] (3) Material A is placed in a quartz boat, and in N 2 Under the atmosphere, place it in a tube furnace, heat up to 800°C at a rate of 12°C / min for pyrolysis for 150 minutes, and then naturally cool down to room temperature to obtain iron-loaded biochar, which is designated as Fe-BC2.

Embodiment 3

[0043] (1) Clean and shred the corn stalks, place them in a blast drying oven, dry them at 110°C for 12 hours, crush them, and pass them through a 100-mesh sieve for later use;

[0044] (2) The biomass obtained by sieving 3g step (1), 2g FeCl 2 , 2.7g Fe(NO 3 ) 3 Put 4.3g of ascorbic acid into a polytetrafluoroethylene-lined bottle of an autoclave, add water and mix thoroughly, heat at 140°C for 8 hours, cool naturally, and vacuum dry at 100°C for 8 hours to obtain material A;

[0045] (3) Material A is placed in a quartz boat, and in N 2 Under the atmosphere, place it in a tube furnace, heat up to 600°C at a rate of 8°C / min for pyrolysis for 100 minutes, and then naturally cool down to room temperature to obtain iron-loaded biochar, which is designated as Fe-BC3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com