Method for growing group III nitride nanometer material

A growth method and nanomaterial technology, applied in the field of growth and preparation of III-nitride nano-arrays, can solve problems that are not conducive to large-scale device production, contamination of reaction chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

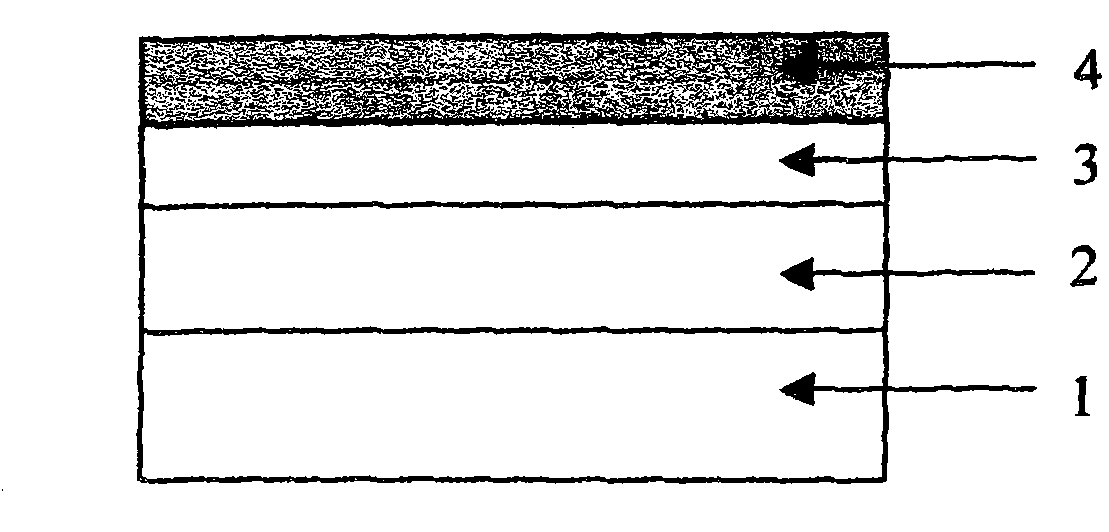

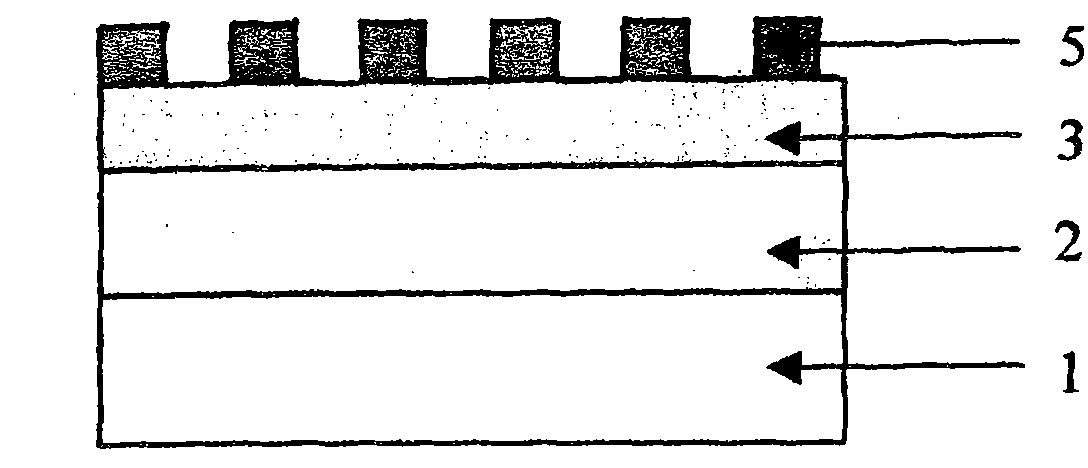

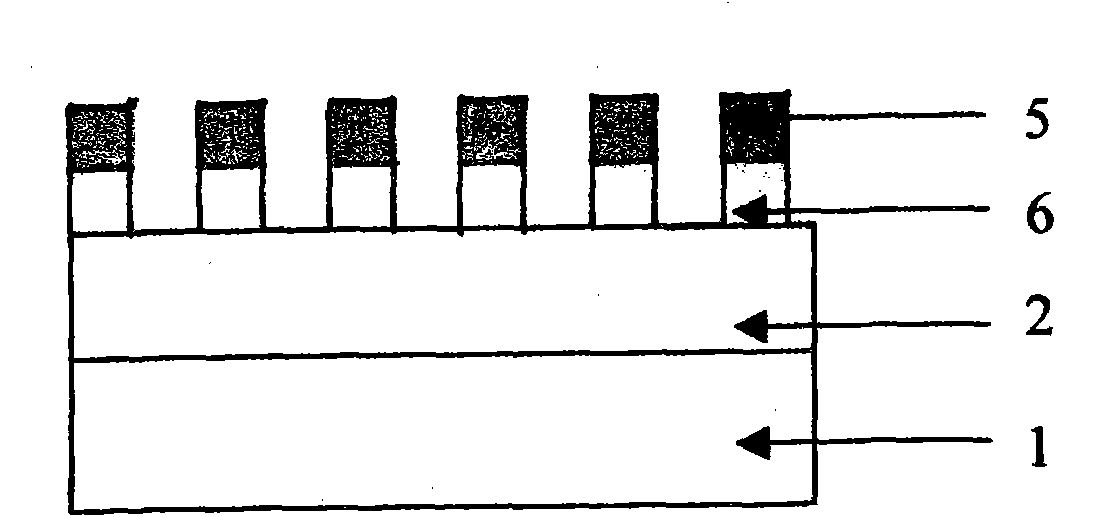

[0029] For the method that usually obtains nanowires or nanopillars, that is, the VLS growth method of metal catalysts, the obtained nanowires or nanopillars are usually randomly distributed on the substrate, and the direction of the nanowires or nanopillars is mostly not vertical. on the substrate. The nanowires need to be peeled off from the substrate to fabricate devices from a single nanocolumn. This is not conducive to mass production of devices. For the MOCVD system, the introduction of other metals outside the reaction system is likely to cause contamination of the reaction chamber. Therefore, a size-controllable and ordered capping layer of (gallium) indium nitride (In(Ga)N) perpendicular to the substrate is grown on GaN nanopillars by MOCVD system to form In(Ga)N / GaN nanopillars. Heterojunction array is a direction worthy of research. The method for growing III-group nitride nanometer materials provided by the invention does not use metal as a catalyst, and for MOC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com