Swing type hydraulic proportioning and servo valve

A swing type, servo valve technology, applied in the field of hydraulic components, can solve the problems of large minimum unit value of feedback angle, low control accuracy, reduced control accuracy, etc., to achieve accurate output flow and pressure, convenient and flexible operation, and control. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

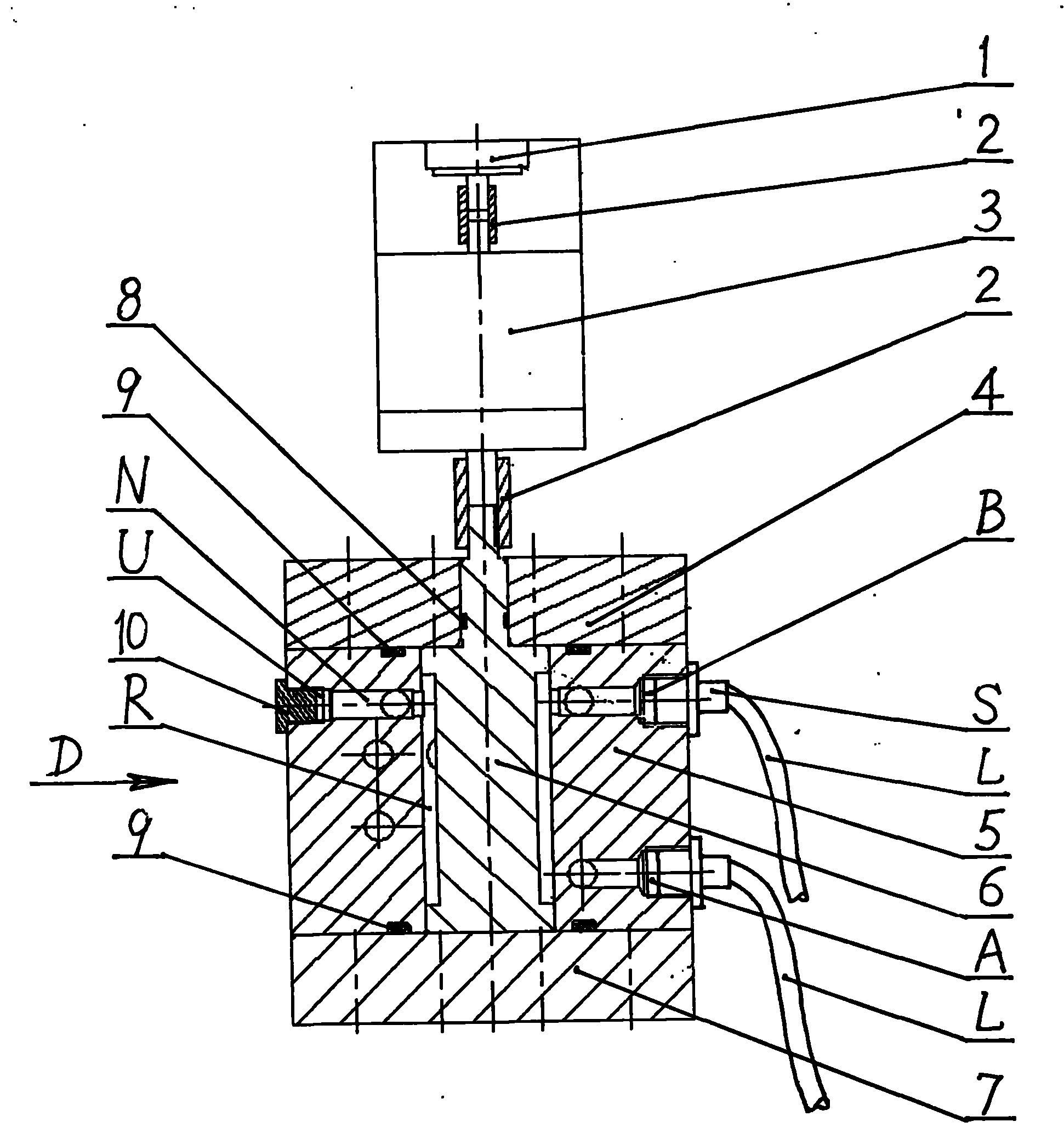

[0034] refer to figure 1 The output shaft at the outer end of the swing motor 3 is connected to the central axis of the angular displacement sensor 1 through the coupling 2, the output shaft at the inner end is connected to the connecting shaft of the spool 6 through the coupling 2, and the spool 6 is installed at the center of the valve body 5 In the valve hole R, the top valve cover 4 and the bottom valve seat 7 close the valve hole R. The back of the valve seat 7 has an ascending oil hole A and a descending oil hole B, which are connected to the oil delivery pipe L through a pipe joint S, and the process hole U opened on the vertical surface of the valve seat 7 is blocked by a screw plug 10 to prevent oil leakage. Valve cover 4 and valve seat 7 are connected and fixed with valve body 5 by bolts.

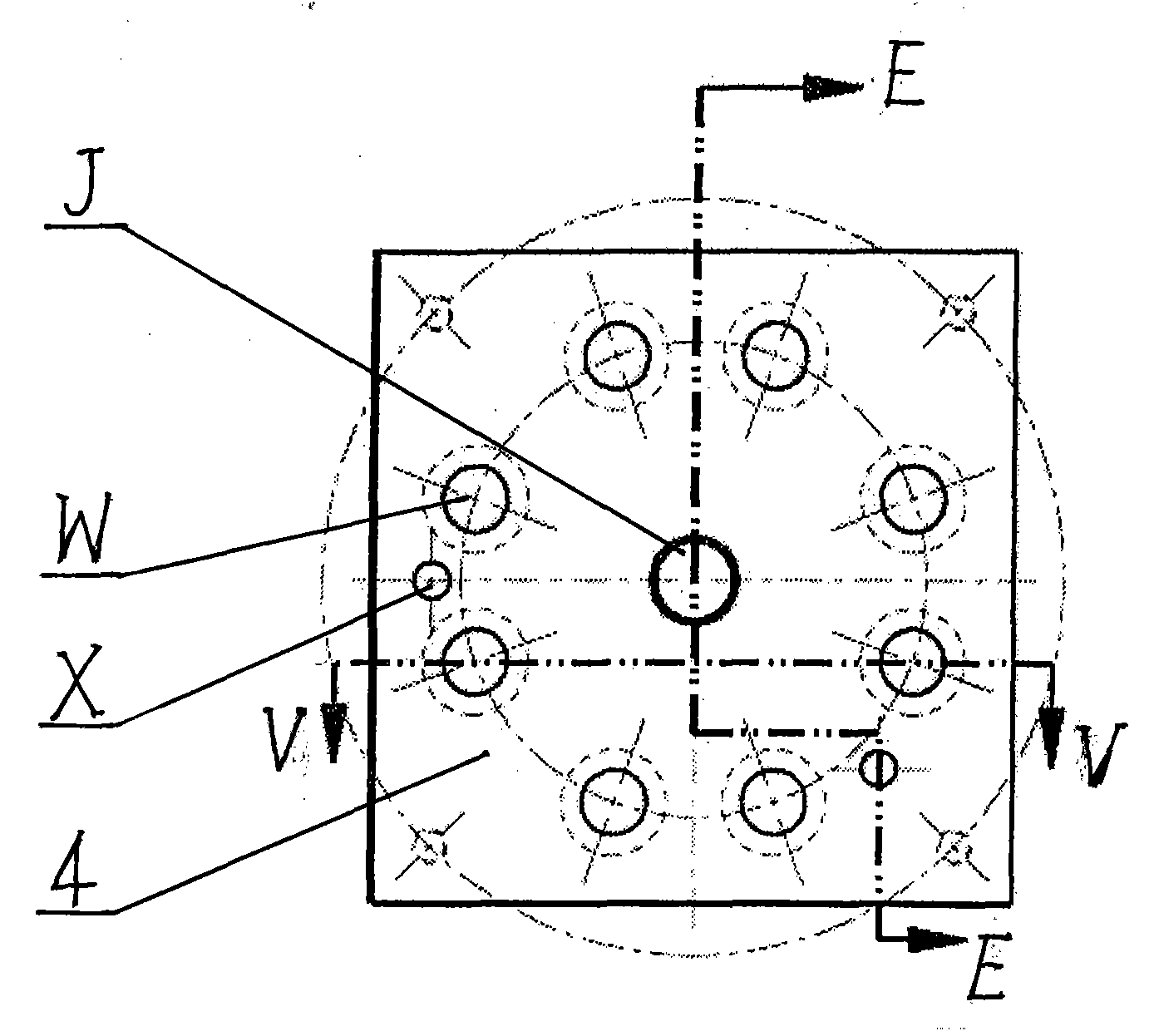

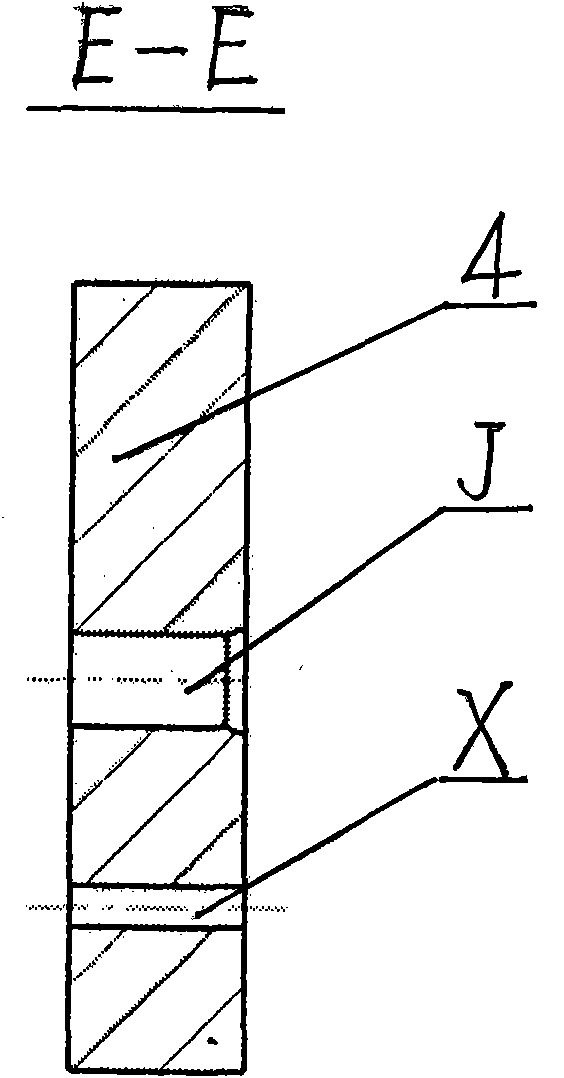

[0035] refer to figure 2 , image 3 , Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com