Lithium battery LiFePO4 anode material with internal three-dimensional conductive structure and preparation method thereof

A lithium iron phosphate, cathode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as poor conductivity, reduce resistivity, increase cycle times and lithium battery life, and increase conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

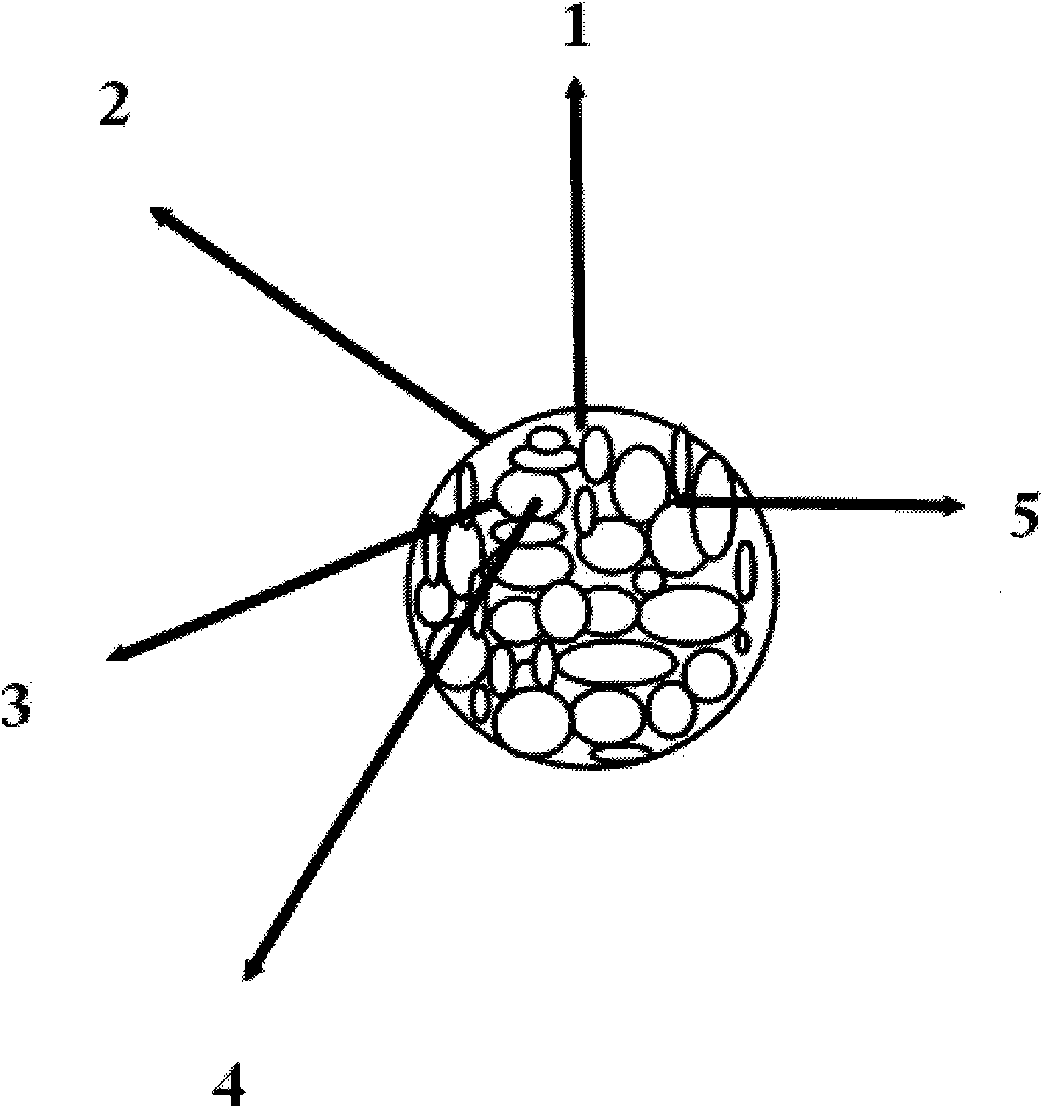

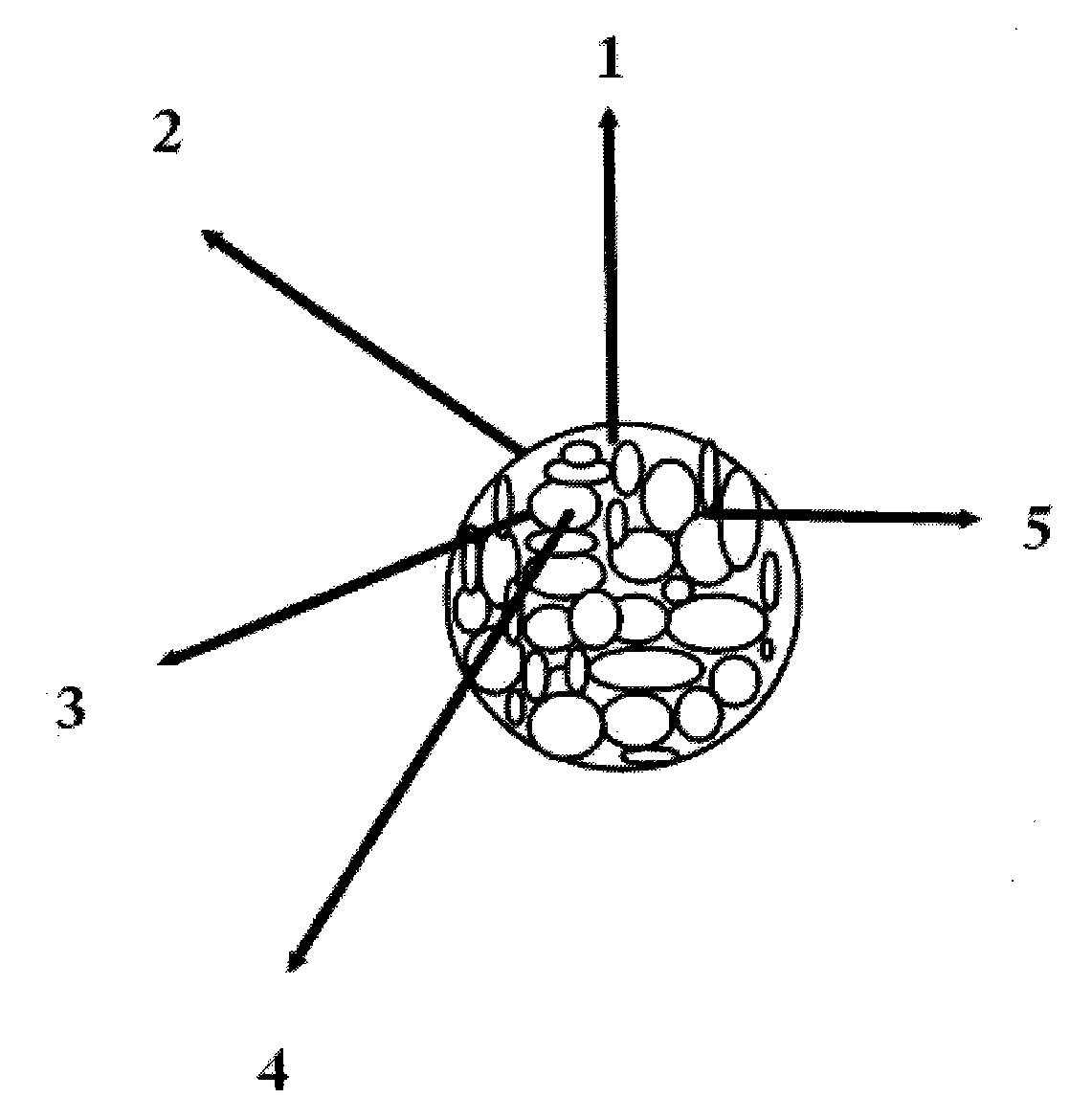

Image

Examples

Embodiment 1

[0018] Put 20 kg of lithium iron phosphate particles and 80 kg of nano-carbon materials into a high-temperature reactor protected by inert gas at the same time. The heating rate of the high-temperature reactor is 150°C per hour, and the temperature rises to 1000°C. The holding time is 2 hours. The stirring speed is 100 rpm; the temperature of the reactor is lowered to 200°C, and the pressure is 10 -5 Pa, reacted for 10 hours, so that the nano-carbon material was coated with lithium iron phosphate particles;

[0019] (2) Coating again: put the cladding in step (1) and nano metal or metal compound according to weight percentage 10%: 90%, put into the high-temperature reactor with inert gas protection at the same time, the heating rate of high-temperature reactor is Raise the temperature by 200°C every 1 hour, the temperature rises to 1000°C, the holding time is 20 hours, and the stirring speed is 300 rpm; the temperature of the reactor drops to 400°C, and the pressure is 10 -5 ...

Embodiment 2

[0022] (1) First coating: Put 60 kg of lithium iron phosphate particles and 40 kg of nano-carbon materials into a high-temperature reactor protected by inert gas at the same time. The heating rate of the high-temperature reactor is 150°C per hour, and the temperature rises to 900°C , the holding time is 10 hours, the stirring speed is 300 rev / min; -5 Pa, reacted for 10 hours, so that the nano-carbon material was coated with lithium iron phosphate particles;

[0023] (2) Coating again: put the cladding in step (1) and the nanometer metal or metal compound according to the weight percentage of 20%: 80%, and put it into a high-temperature reactor with inert gas protection at the same time, and the temperature rise rate of the high-temperature reactor is Raise the temperature by 200°C every 1 hour, the temperature rises to 800°C, the holding time is 10 hours, and the stirring speed is 300 rpm; the temperature of the reactor drops to 800°C, and the pressure is 10 -5 Pa, react for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com