Lithium ion secondary battery and cathode material prepared by same

A technology for secondary batteries and positive electrode materials, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as high-temperature gas production, and achieve high energy density, good high-temperature storage performance, and large-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

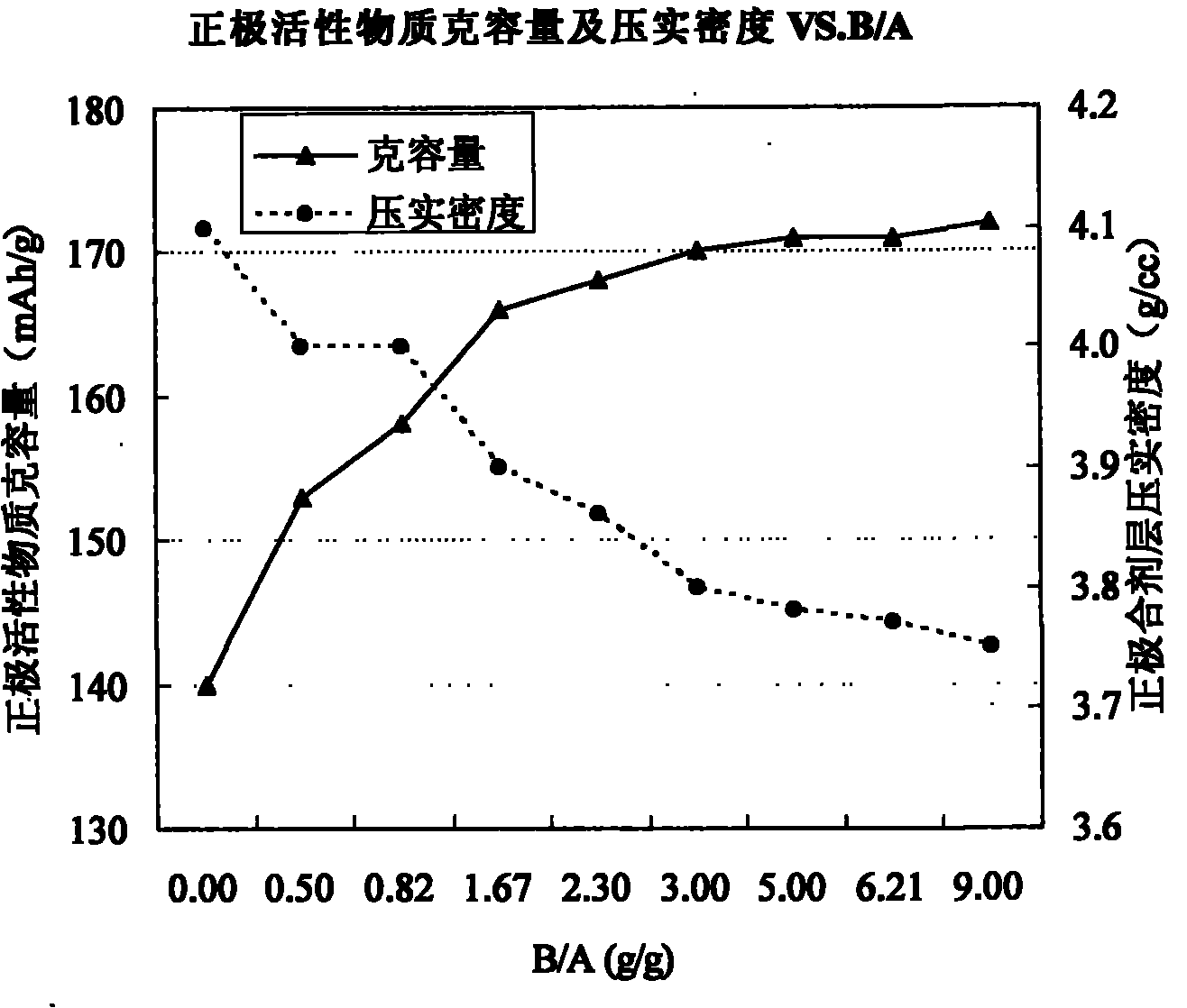

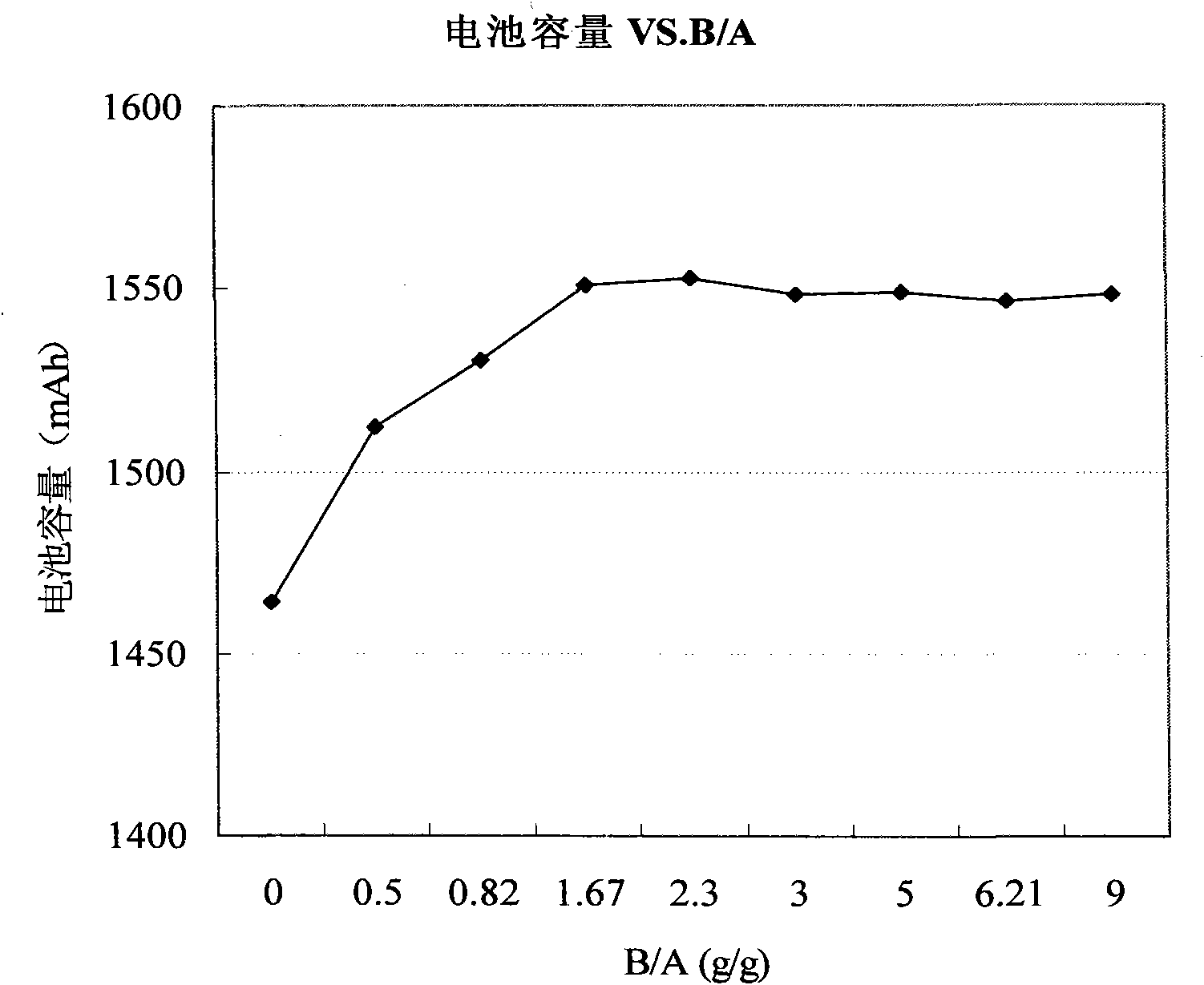

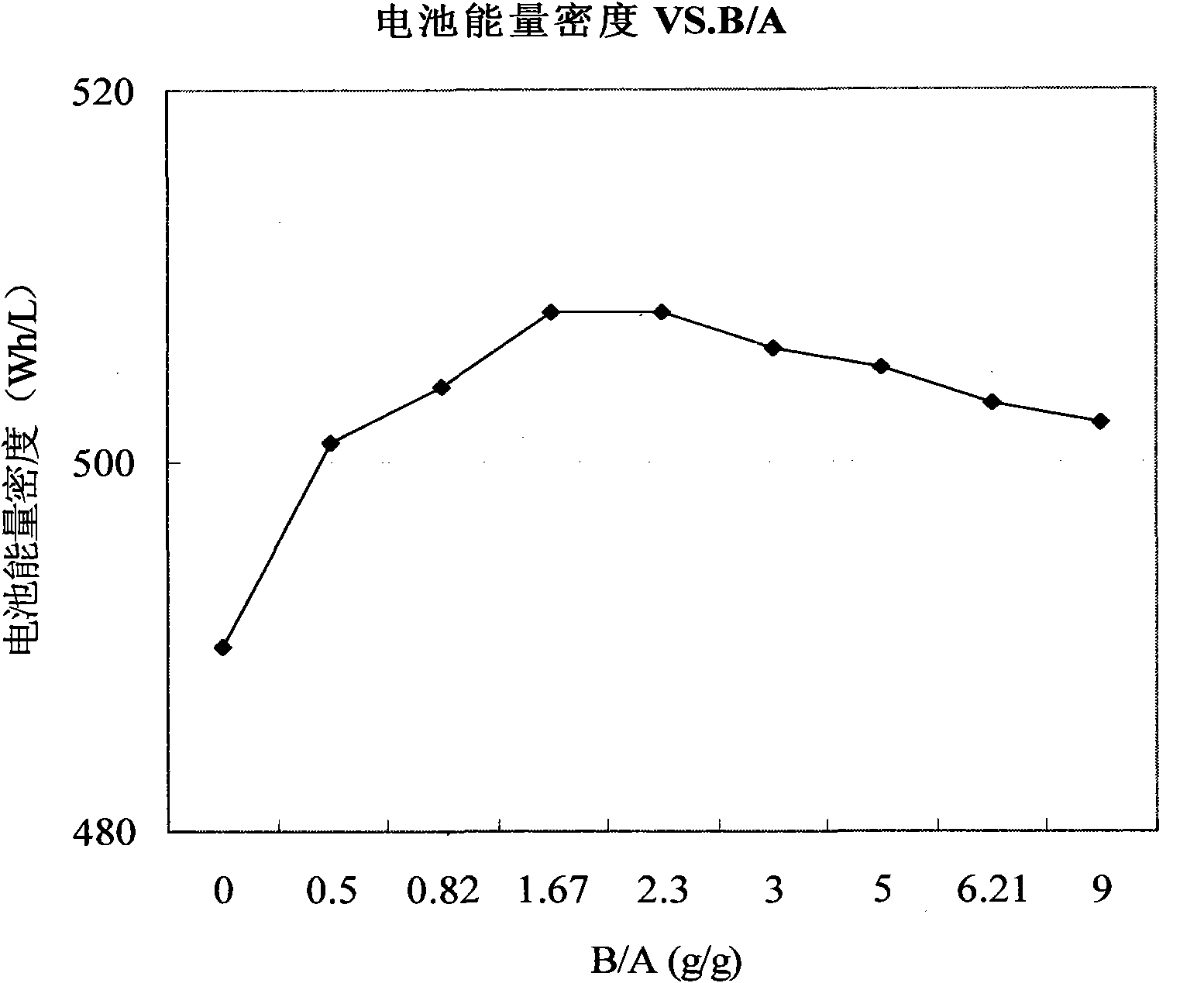

Embodiment 1

[0041] Positive electrode production

[0042] Use LiCoO with an average particle diameter D50 of 18 μm 2 As the lithium cobaltate-based active material A, that is, LiCoO with a particle size of less than 18 μm 2 The particle volume accounts for 50% of the total particle volume; use Li with an average particle size D50 of 12 μm 1.02 Ni 0.78 co 0.20 al 0.02 o 2 As high-nickel active material B, that is, Li with a particle size of less than 12 μm 1.02 Ni 0.78 co 0.2 0Al 0.02 o 2 The particle volume accounts for 50% of the total particle volume. The high-nickel active material B is washed with deionized water for 15 minutes before mixing to achieve the purpose of removing lithium-containing impurities (such as lithium carbonate, lithium hydroxide, etc.), and dried in a vacuum at 100°C and a vacuum pressure of less than 100Pa after centrifugation 20 hours to remove moisture. Adjust the weight ratio B / A of the high-nickel active material B to the lithium cobaltate-based ...

Embodiment 2

[0048] Use LiCoO with an average particle diameter D50 of 18 μm 2 As the lithium cobaltate-based active material A, Li with an average particle diameter D50 of 12 μm was used. 1.02 Ni 0.78 co 0.20 al 0.02 o 2 As the high-nickel active material B, the high-nickel active material B was subjected to the same pretreatment method as in Example 1, but after centrifugation, it was dried in vacuum at a vacuum pressure of less than 100 Pa for 15 hours at 80° C. to remove moisture. Adjust the weight ratio B / A of the high-nickel active material B to the lithium cobaltate-based active material A to be 1.67. And change the compacted density of the positive electrode membrane to 3.9g / cc. Except for this, a lithium ion secondary battery was fabricated in the same manner as in Example 1.

Embodiment 3

[0050] Use LiCoO with an average particle diameter D50 of 18 μm 2 As the lithium cobaltate-based active material A, Li with an average particle diameter D50 of 12 μm was used. 1.02 Ni 0.78 co 0.20 al 0.02 o 2 As the high-nickel active material B, the high-nickel active material B was subjected to the same pretreatment as in Example 1, and the weight ratio B / A of the high-nickel active material B to the lithium cobaltate-based active material A was adjusted to 3. And change the compacted density of the positive electrode membrane to 3.8g / cc. Except for this, a lithium ion secondary battery was fabricated in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com