Driving device and driving method for synchronous rectifying tube

A synchronous rectifier tube and synchronous rectification technology, which is applied to the output power conversion device, the conversion of AC power input to DC power output, climate sustainability, etc. Signal acquisition difficulties and other problems, to achieve the effect of reducing costs, simple and effective synchronous rectification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

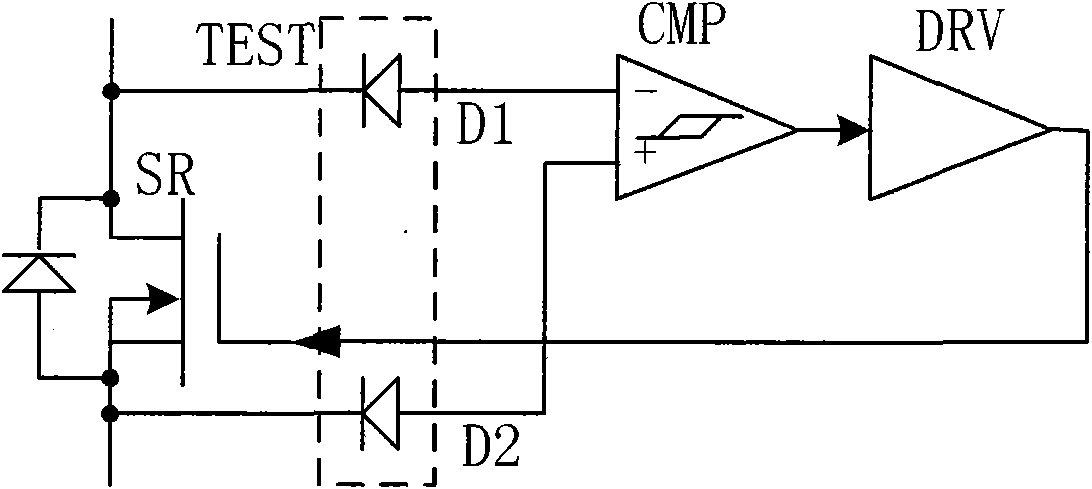

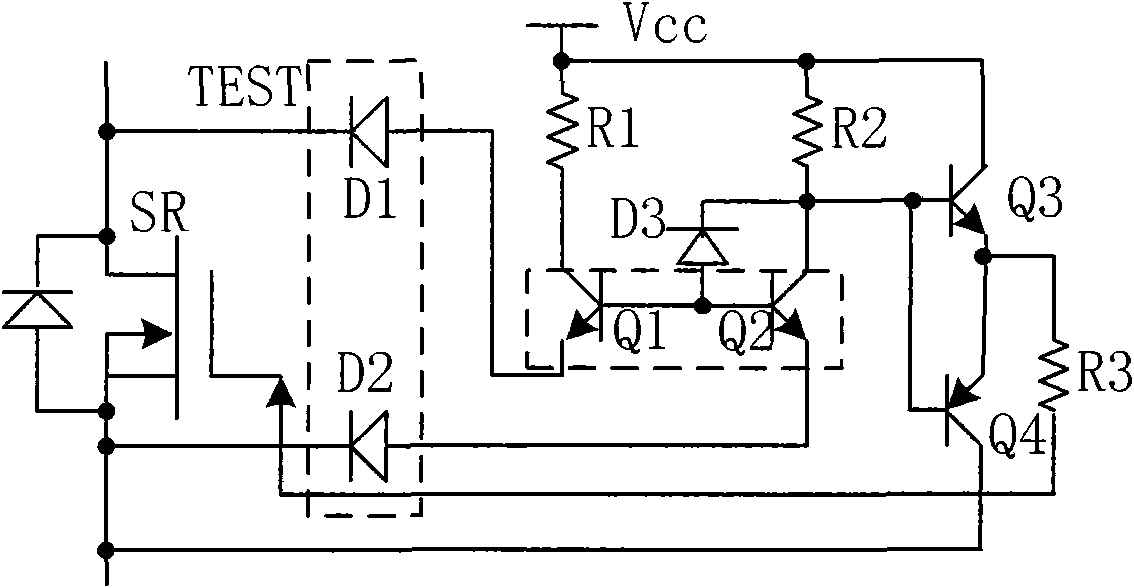

[0033] Such as image 3 As shown, the voltage detection isolation circuit TEST preferably includes a first diode D1 and a second diode D2, the cathode of the first diode D1 is connected to the drain of the synchronous rectification MOSFET SR, and the cathode of the second diode D2 is connected to The source of the synchronous rectification MOSFET SR, the anodes of the first diode D1 and the second diode D2 are respectively connected to the inverting input terminal - and the non-inverting input terminal + of the comparator CMP.

[0034] The comparison circuit CMP preferably includes a third diode D3, a first triode Q1 and a second triode Q2, wherein the emitter of the first triode Q1 is connected to the anode of the first diode D1, and the first triode The collector of the transistor Q1 is connected to the auxiliary power supply Vcc through the first resistor R1, the bases of the first transistor Q1 and the second transistor Q2 are connected to the anode of the third diode D3, ...

Embodiment 2

[0038] Such as Figure 4 As shown, the only difference from the previous embodiment is that the drive circuit uses an integrated drive IC chip instead of image 3 In the push-pull circuit composed of the third and fourth triodes Q3 and Q4. The input terminal of the integrated driver IC is coupled to the output terminal of the comparison circuit CMP, and its output terminal is coupled to the gate of the synchronous rectification MOSFET.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com