Multilayered body for medical containers and medical container

A medical container and multi-layer technology, which is applied in the direction of medical containers, medical packaging, household containers, etc., can solve the problem of reducing the concentration of medicines, and achieve the effects of good adhesion resistance, good bonding, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

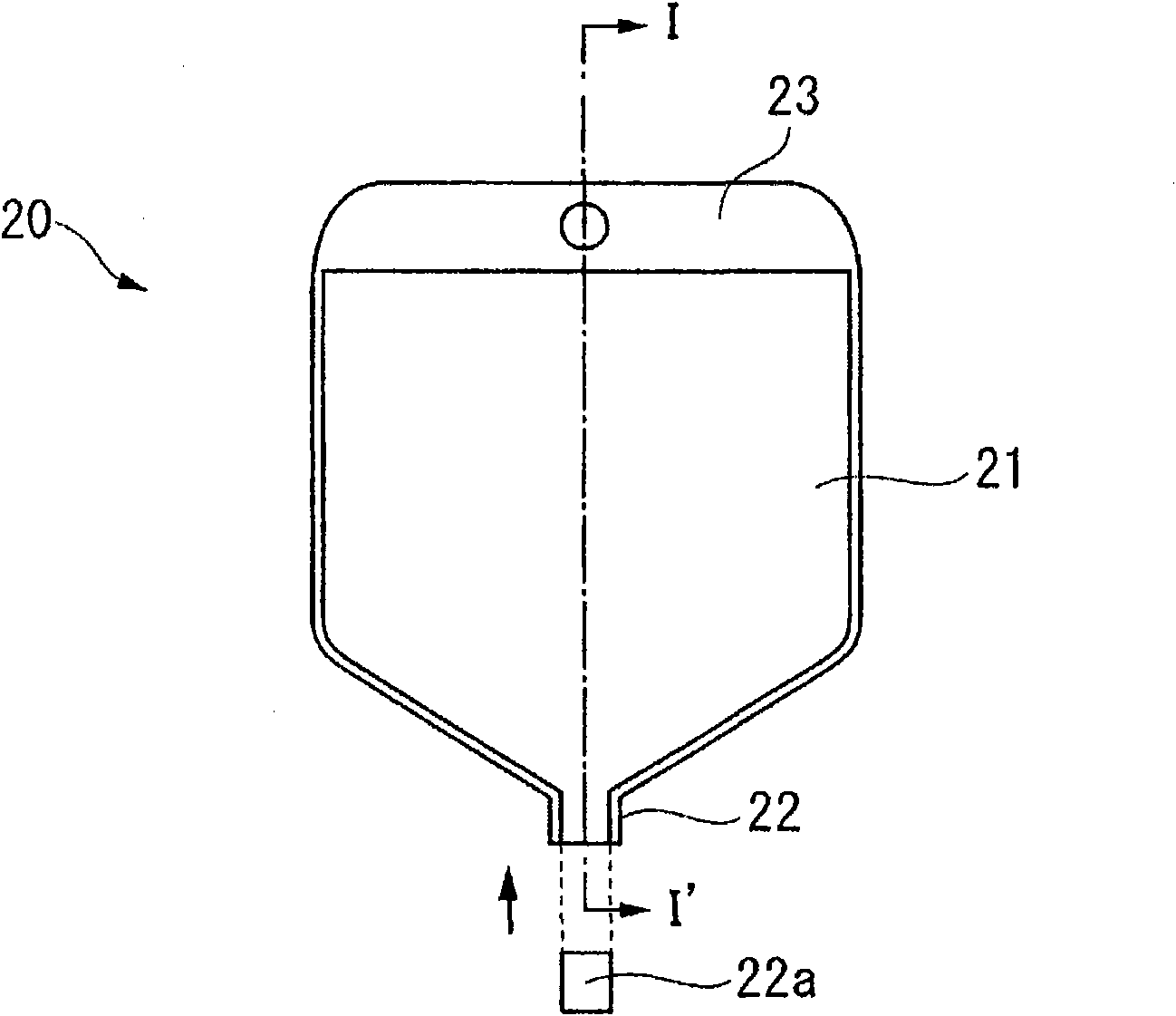

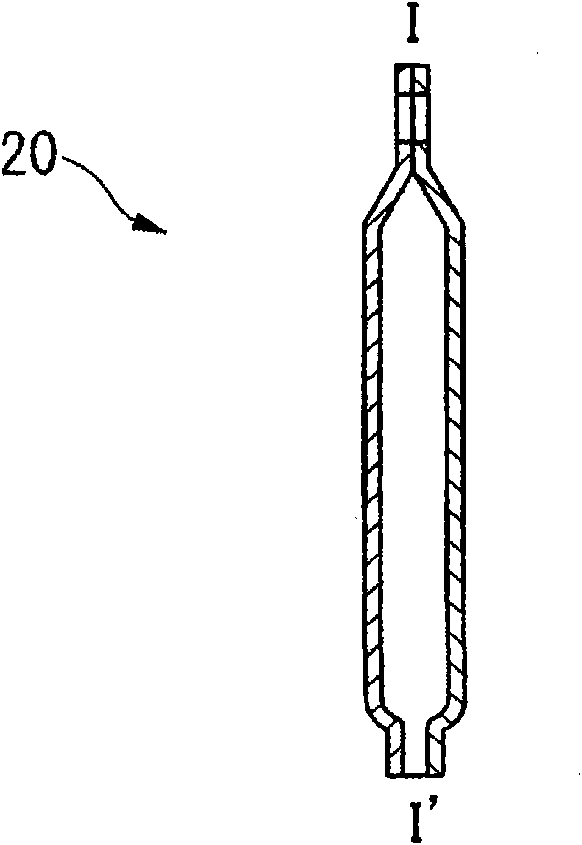

[0094] The medical container 20 of Fig. 2 filled with 100 ml of water was manufactured in the following manner.

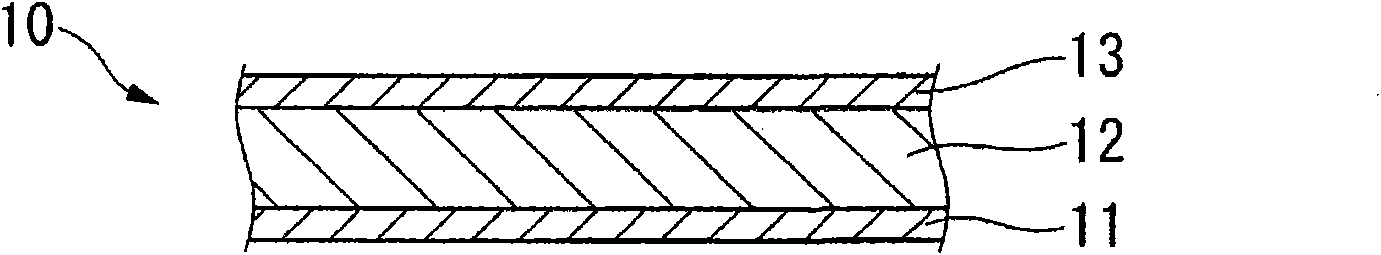

[0095] First, the housing part 21 and the mouth part 22 are integrally molded by the multi-layer blow molding method using a multi-layer blow molding machine. , and a blow molded body with a three-layer structure of the outermost layer with a thickness of 20 μm is formed. Next, 100 ml of water is filled into the accommodating portion 21 from the mouth portion 22 , and then the rubber stopper body 22 a and the mouth portion 22 are heat-sealed to seal the medical container 20 . As the rubber plug body 22a, the melt flow rate (hereinafter referred to as "MFR" at 280° C. based on ISO 1133, which is set by injection molding on the outer peripheral part. In addition, in Examples and Comparative Examples, when MFR is measured, All of the loads are 21.18N.) The rubber of the layer formed by the cyclic polyolefin "Zonex (manufactured by Nippon Zenon Co., Ltd.)" (hereinafte...

Embodiment 2

[0121] Except for changing the composition of the outermost layer and the composition of the mouth portion 22 in Example 1, the medical container 20 was obtained in the same manner.

[0122] The MFR at 190°C for the outermost layer is 1.1g / 10 minutes, and the density is 0.927g / cm 3 High-pressure low-density polyethylene "Novatec (manufactured by Japan Polyechlen Co., Ltd.)" has an MFR of 3.5 g / 10 minutes at 190°C and a density of 0.956 g / cm 3 High-density polyethylene "Novatec (manufactured by Nippon Polyechelen Co., Ltd.)" was mixed at a mass ratio of 7:3.

[0123] The mouth 22 is constructed by heating a cylindrical member made of cyclic polyolefin manufactured by injection molding in a preheated mold set at 250° C. The inner 22 side of the mouth of the housing part 21 formed by the body, and heat-sealed installation at 220 ° C. In addition, after filling 100 mL of water, a rubber stopper was filled in the cylinder member, and an annular cover member was further arranged s...

Embodiment 3

[0125] A medical container 20 was obtained in the same manner as in Example 1 except that only COP2 was used for forming the innermost layer, and the same evaluation was performed. The results are shown in the table.

[0126] In addition, in this embodiment, as the rubber plug body 22a, a layer formed of LLDPE used as an intermediate layer is provided on the outer peripheral portion of the rubber plug by injection molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com