Method for processing refined millet

A processing method and technology of millet, applied in the direction of grain processing, application, grain depodization, etc., can solve the problems of inability to realize the industrial production of refined millet, unable to meet the requirements of millet processing, etc., to fill the gap in technology and market, and prolong the shelf life of freshness. , scientific and reasonable effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

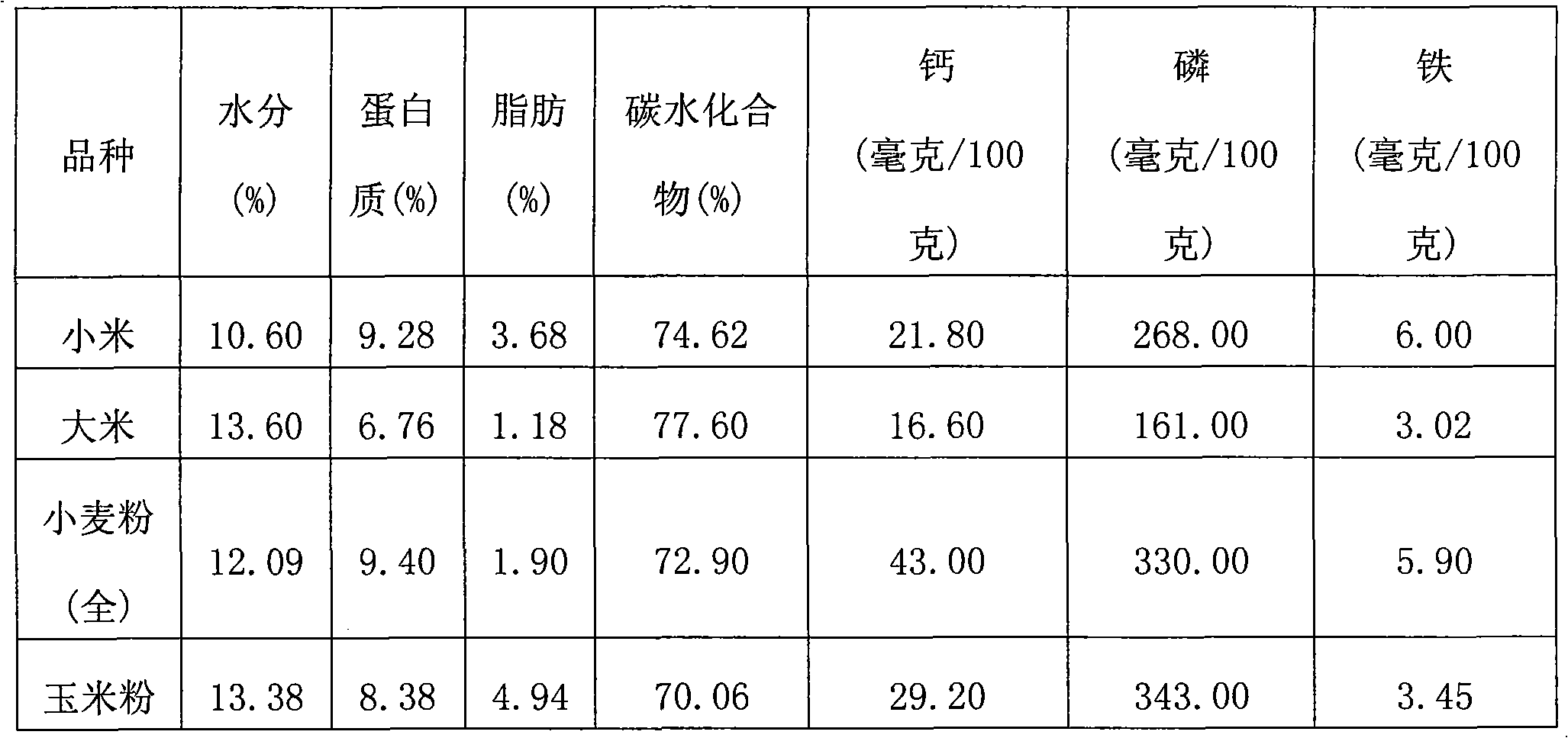

[0017] Raw grain selection: Design and use a 150T millet production line per day, and select high-quality millet that meets the GB8232-1987 standard in Zhuluke Town, Jianping, Liaoning Province, and the first-class standard for large grains, such as Kaoshanhong variety processing 150T.

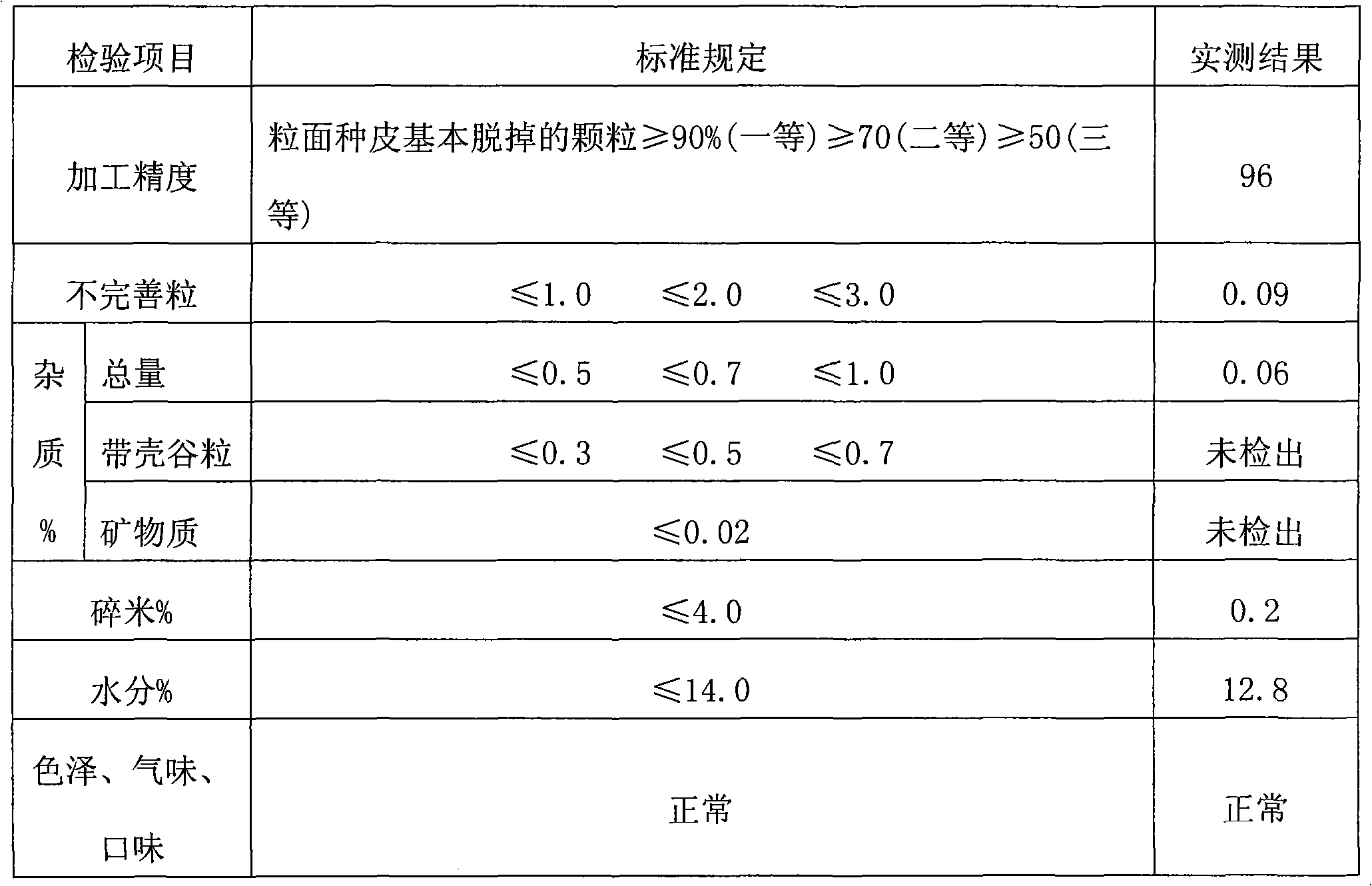

[0018] Inspection standard: GB / T11766-1989, implement GB2715-1981 food hygiene standard, without any additives, and the shelf life is 12 months.

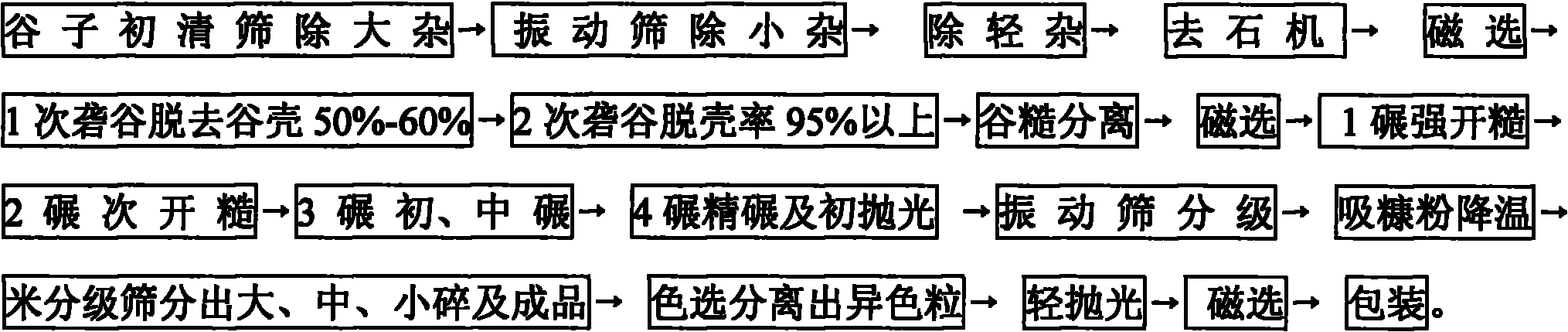

[0019] Processing technology: initial cleaning screen (remove large impurities) → vibrating screen (remove small impurities) → vertical air suction channel (remove light impurities) → stone remover (remove side-by-side stones) → magnetic separation (remove magnetic metal objects) → 1 time of hulling (about 50%-60% of the husk removed) → 2 times of husking (to make the husk rate reach more than 95%) → separation of grain and roughness → magnetic separation (removal of magnetic metal objects) → 1 milling (for Strong roughening, achieve strong rougheni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com