Track plate prefabrication concrete transport and distribution system

A precast concrete and distribution system technology, applied in clay preparation devices, mixing operation control, mixing plants, etc., can solve the problems of difficult control of concrete quality, instability of mixing stations, long transportation distance, etc., to improve labor productivity and convenience. Concrete transportation, the effect of speeding up the production schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

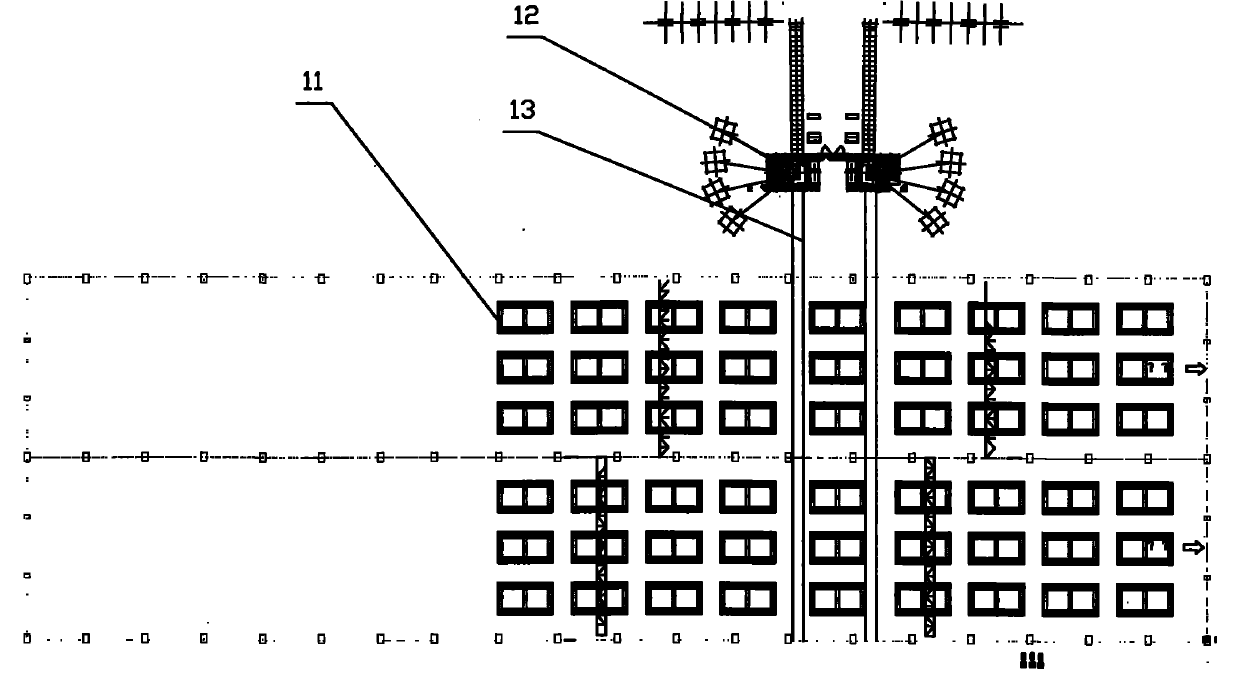

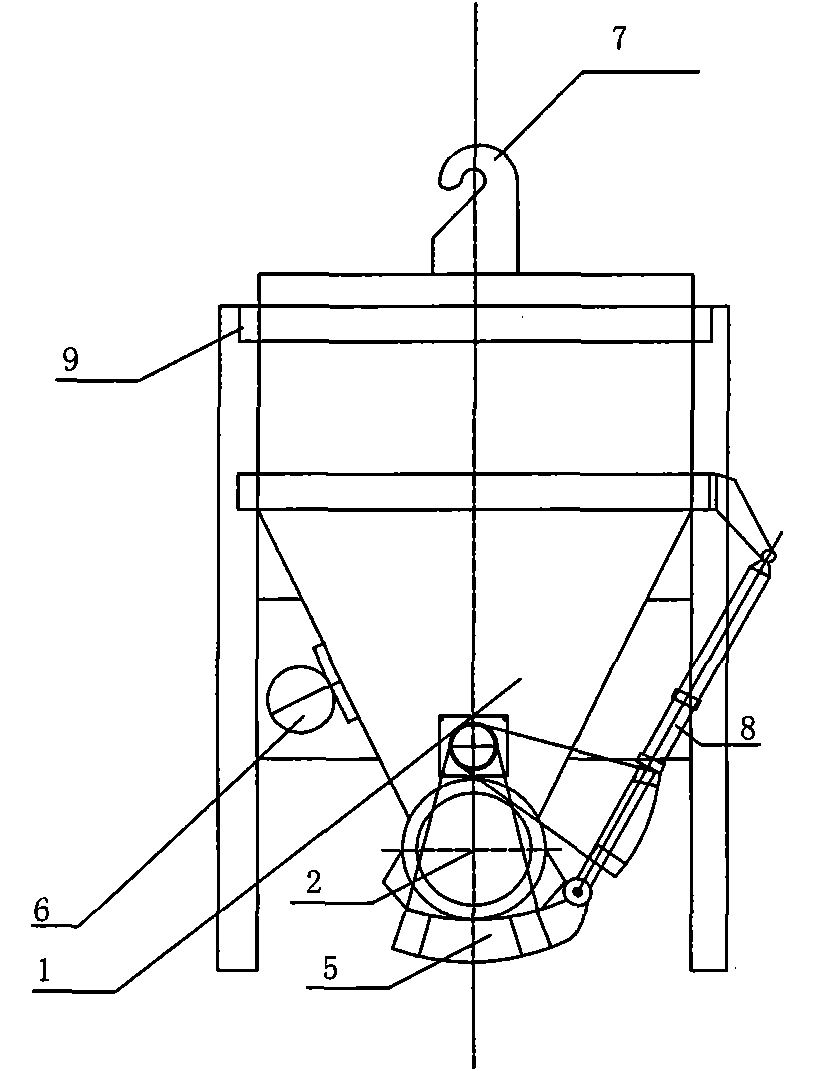

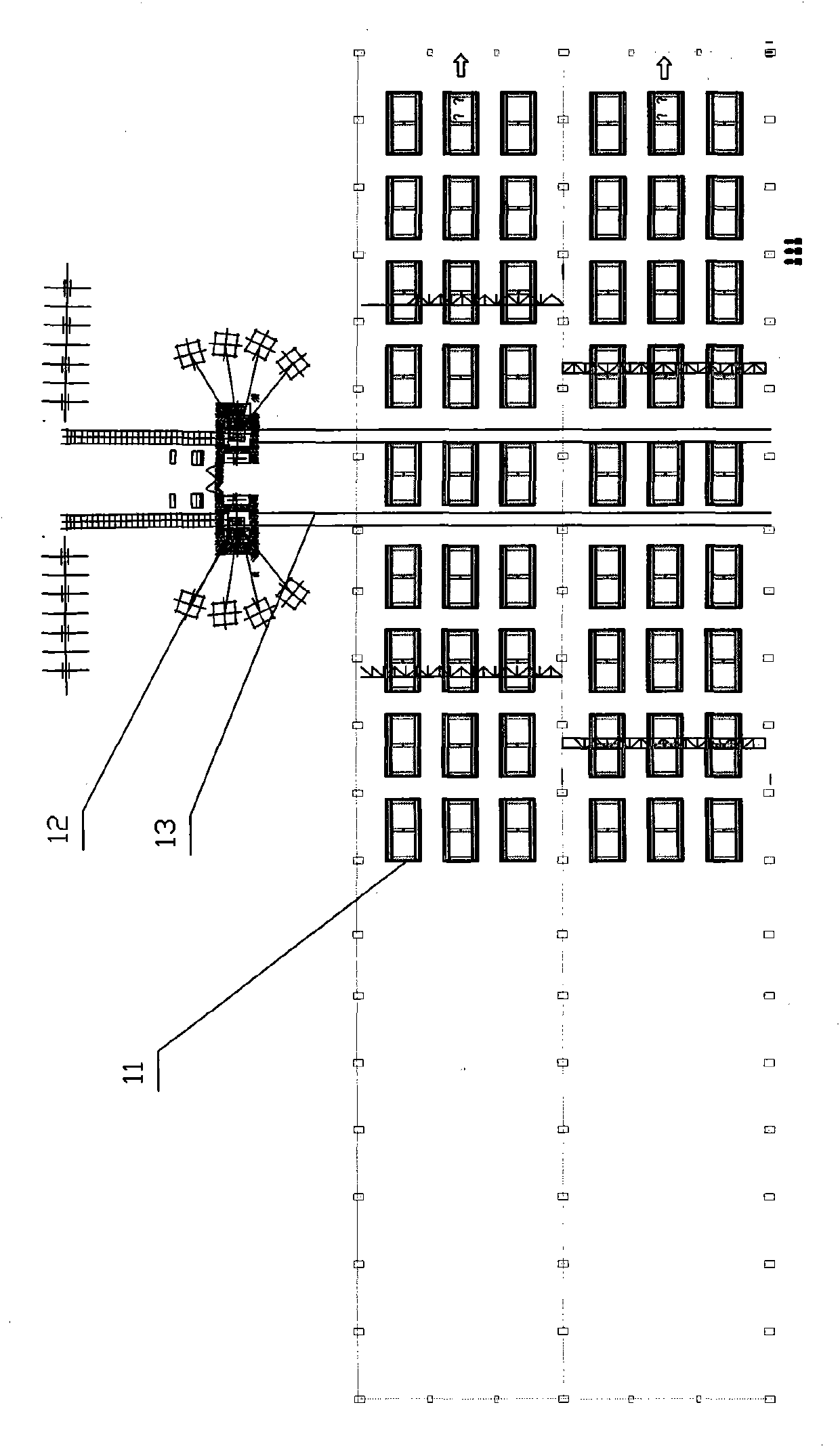

[0016] The first stage: This scheme is more suitable for a new board factory. When designing the factory construction scheme, accurately locate the double-body mixing station and the location of the track slab prefabrication workshop on the planning map. Construction of mixing stations and workshops. At the same time, attention should be paid to the position of the H-shaped steel column in the prefabrication workshop, and the working space of the two tracks should be avoided. When designing the track height, it must be ensured that the height difference between the outlet of the mixing station and the bottom of the distributing machine is less than 2m.

[0017] The second stage: when the track slab is prefabricated, the double mixing station starts at the same time, and two tracks are used to supply any one of the two track slab production lines. The concrete is lowered into the placing machine. After the camera under the mixing station confirms that the material is loaded, p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap