Double-hearth high temperature smelting furnace

A high-temperature melting, dual-furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of furnace damage, sharp drop in crucible temperature, long transfer process time, etc. The effect of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

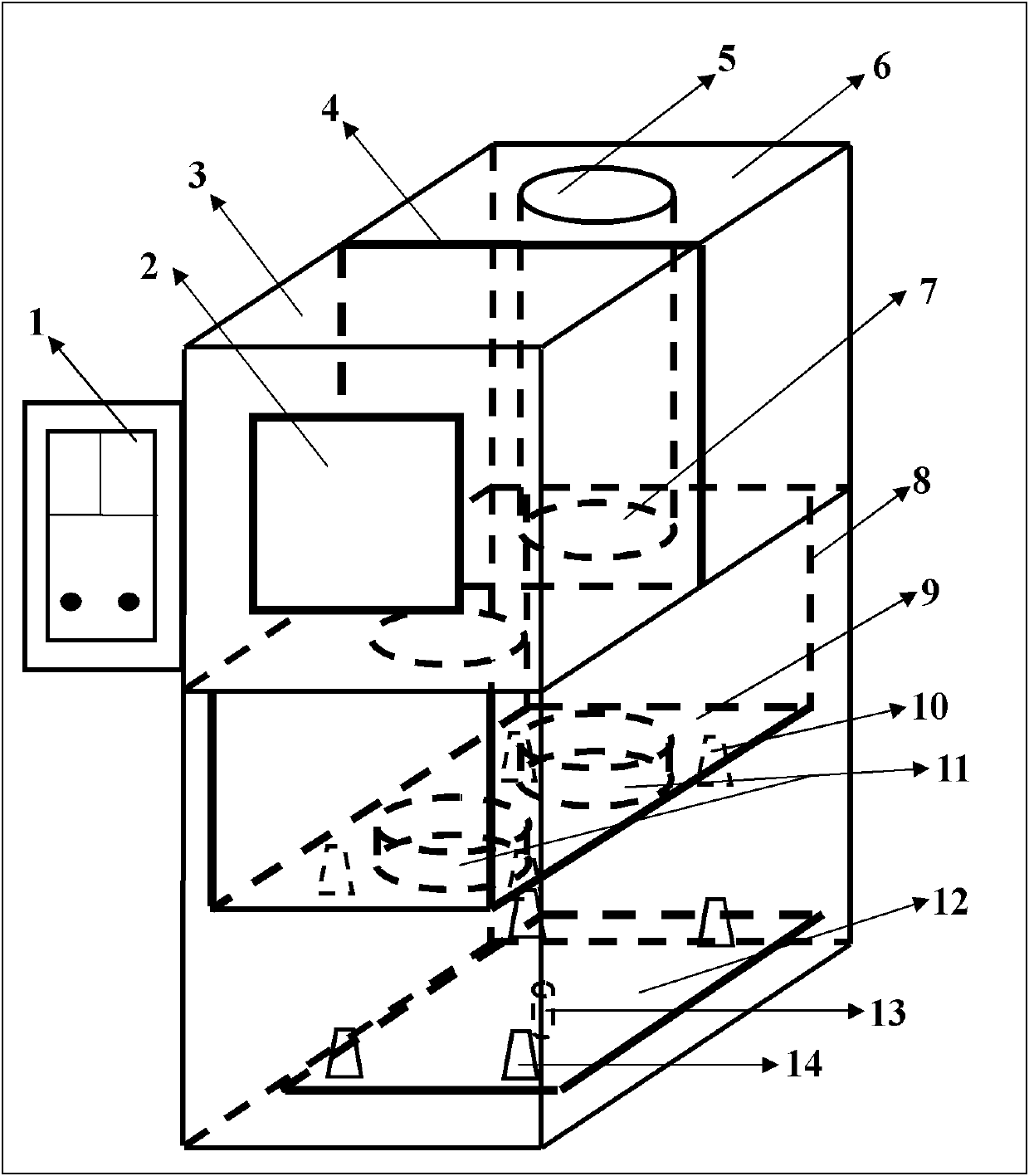

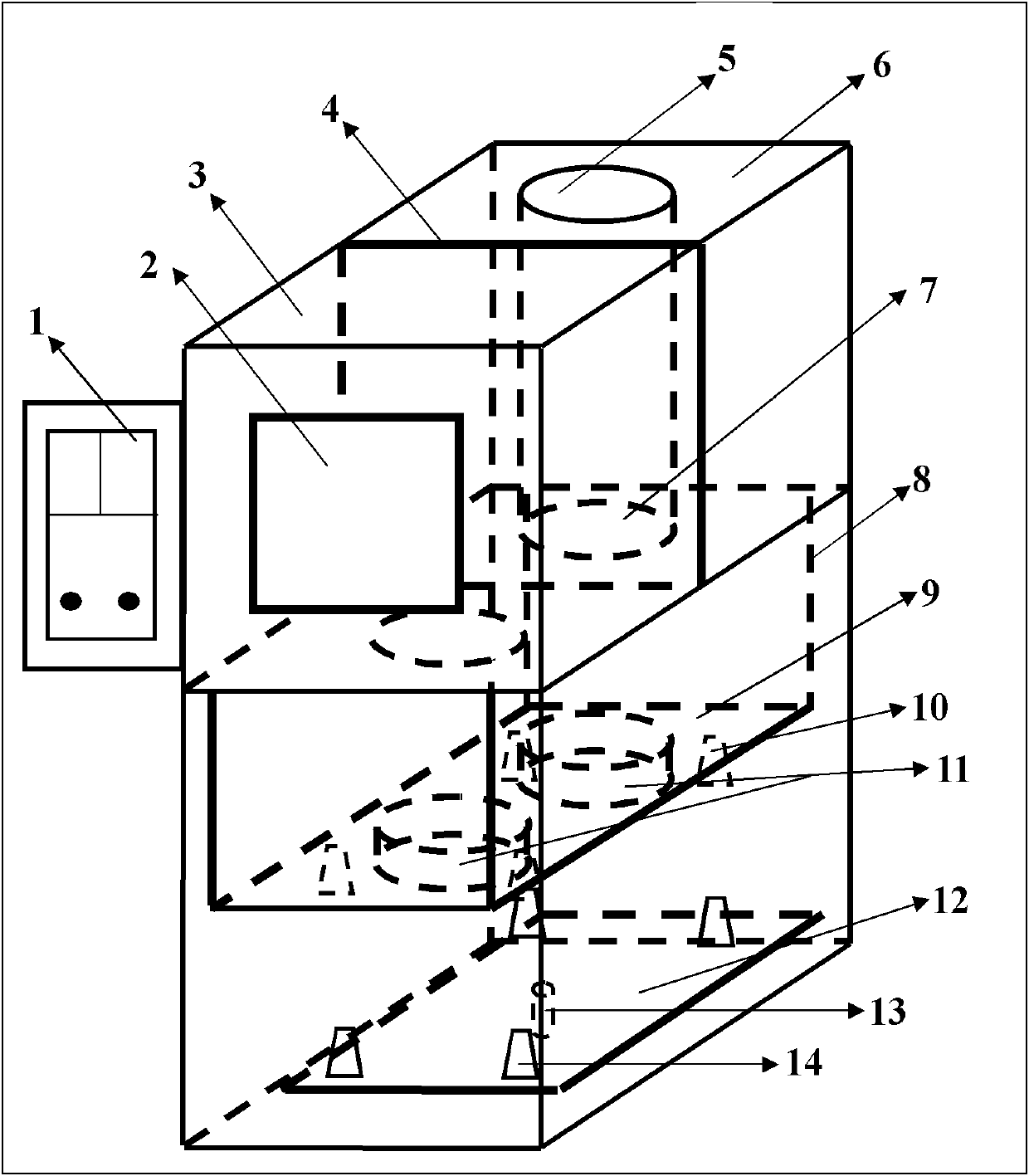

[0017] according to figure 1 And take melting converter slag as an example to further describe the embodiment of the present invention:

[0018] The main component of converter steel slag is SiO 2 , CaO , Al 2 o 3 , MgO, FeO, Fe 2 o 3 And elemental Fe, whose melting point is about 1600°C, was melted in a magnesia crucible for experiments.

[0019] First, put the weighed converter steel slag into the crucible, lower the furnace chassis 9, because it is the first time to heat up, the hollow ball refractory brick 11 and the furnace are at room temperature, so the crucible can be directly placed under the box furnace 3 Hollow ball refractory brick 11 at the front end of the control box 1, and then press the turn button on the control box 1 to drive the furnace bottom plate 9 to rotate backwards, so that the crucible is turned to the bottom of the pit furnace 6 at the rear end, so that the crucible can be avoided. Put it on the hollow spherical refractory brick below the rear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com