Manufacturing method of GaN-based LED by annealing to strip and inverse SiC substrate

A manufacturing method and substrate technology, applied in the field of optoelectronics, can solve the problems of less than 50% front light extraction efficiency, inability to adopt flip-chip structure of LED, low power, etc., and achieve the effect of solving low light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

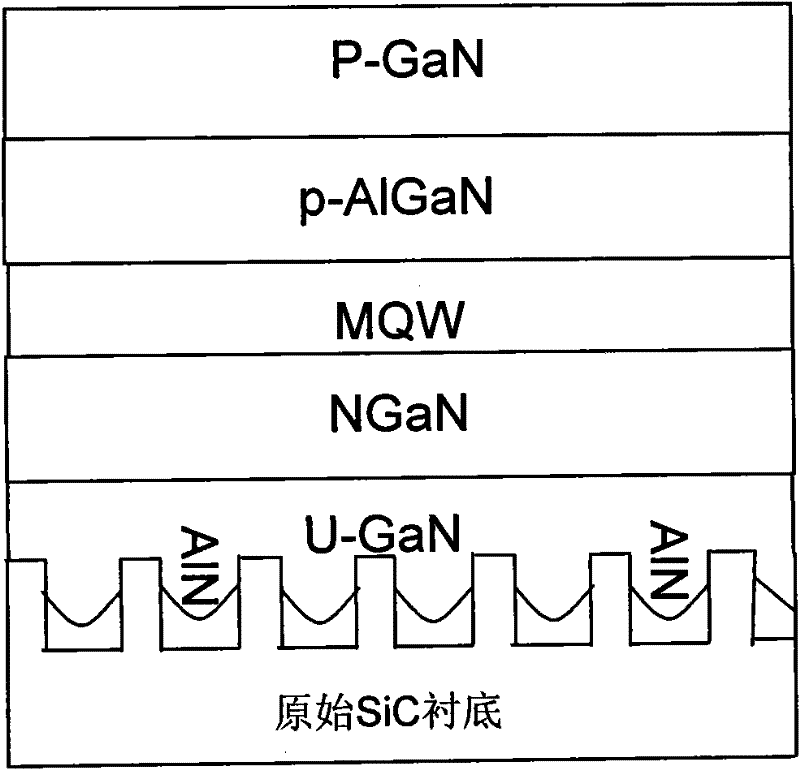

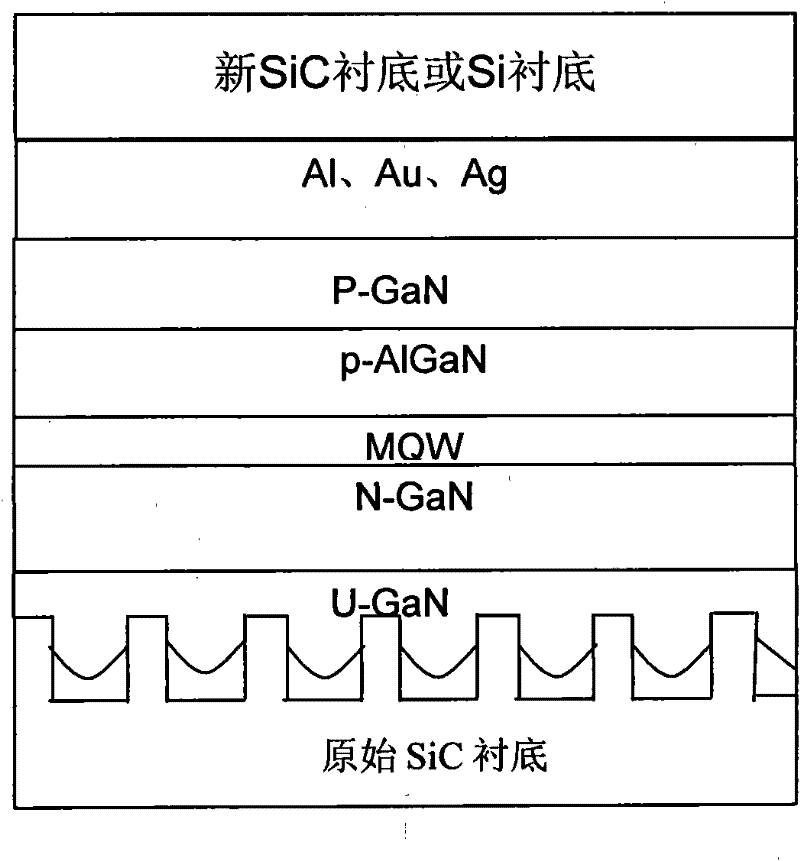

[0028] The manufacturing method of the flip-chip SiC substrate GaN-based LED of the present invention utilizes a graphic substrate and annealing stripping, and the specific manufacturing process is as follows:

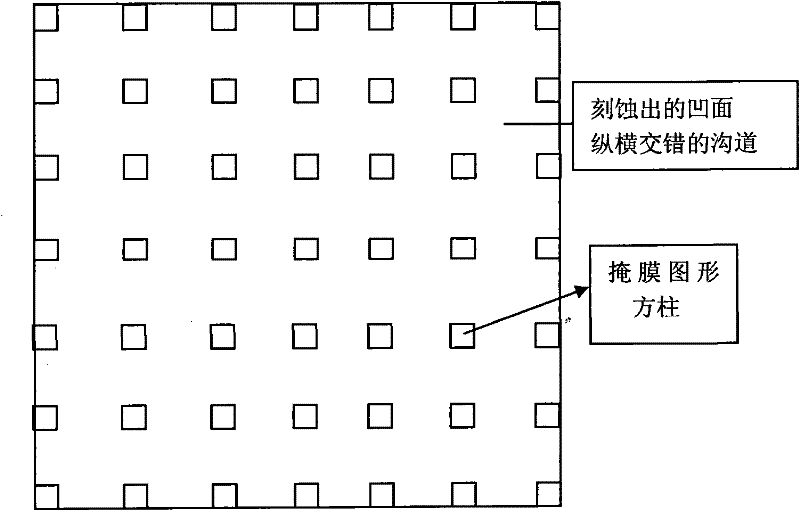

[0029] 1 Fabrication of the original SiC pattern substrate by dry etching

[0030] (1) Evaporate a layer of thickness on the original SiC substrate SiO 2 As a mask, the SiO 2 Coat the photoresist on the mask, pass the pre-engraved pattern mask on the photoresist, and use the photolithography machine to expose and carve the required mask pattern (that is, the place outside the pattern mask protection is exposed).

[0031] (2) Then put it into a 0.5%-5% sodium hydroxide solution for about 10 seconds to 60 seconds to develop, and the photoresist will be removed when developing the place exposed by photolithography, exposing the SiO outside the pattern protection 2 , use HF acid to etch away the SiO exposed on the surface after development 2 , these places expose the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com