Variable-frequency and variable-speed motor

A variable speed motor and frequency converter technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of human health hazards, interference with the communication environment, equipment malfunctions, etc., to reduce human health hazards, reduce pollution, reduce Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

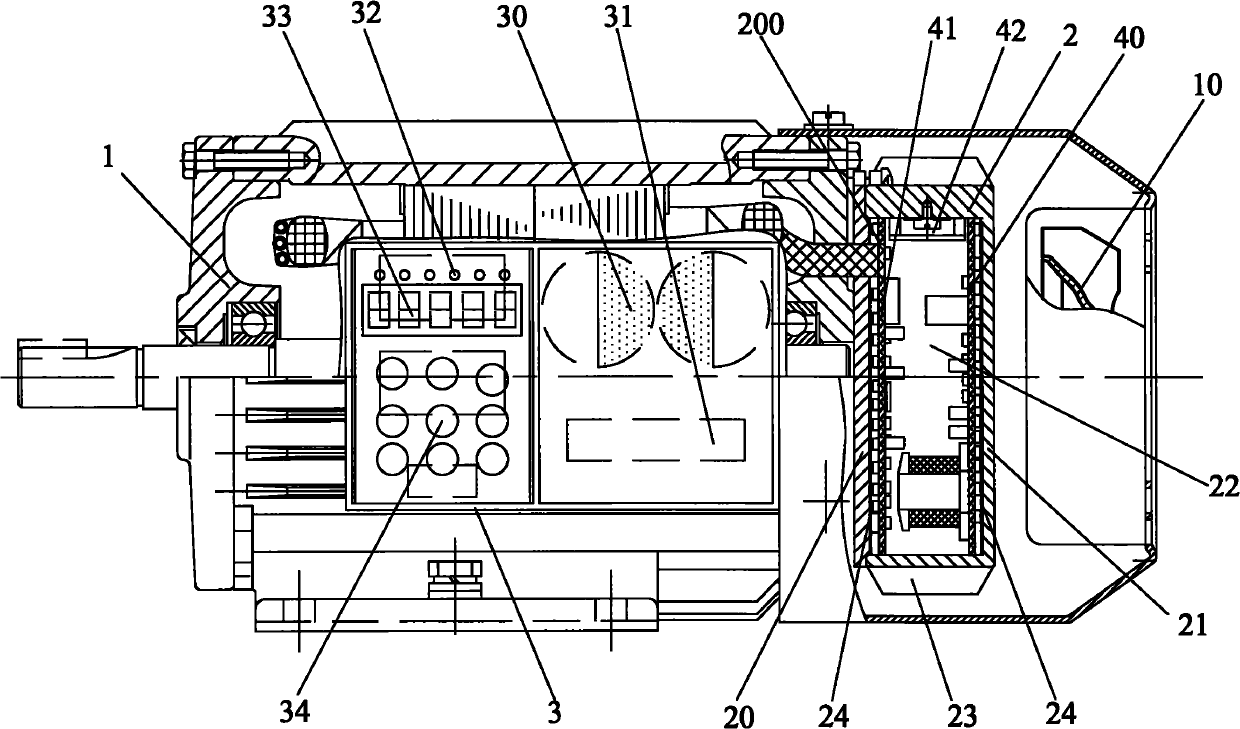

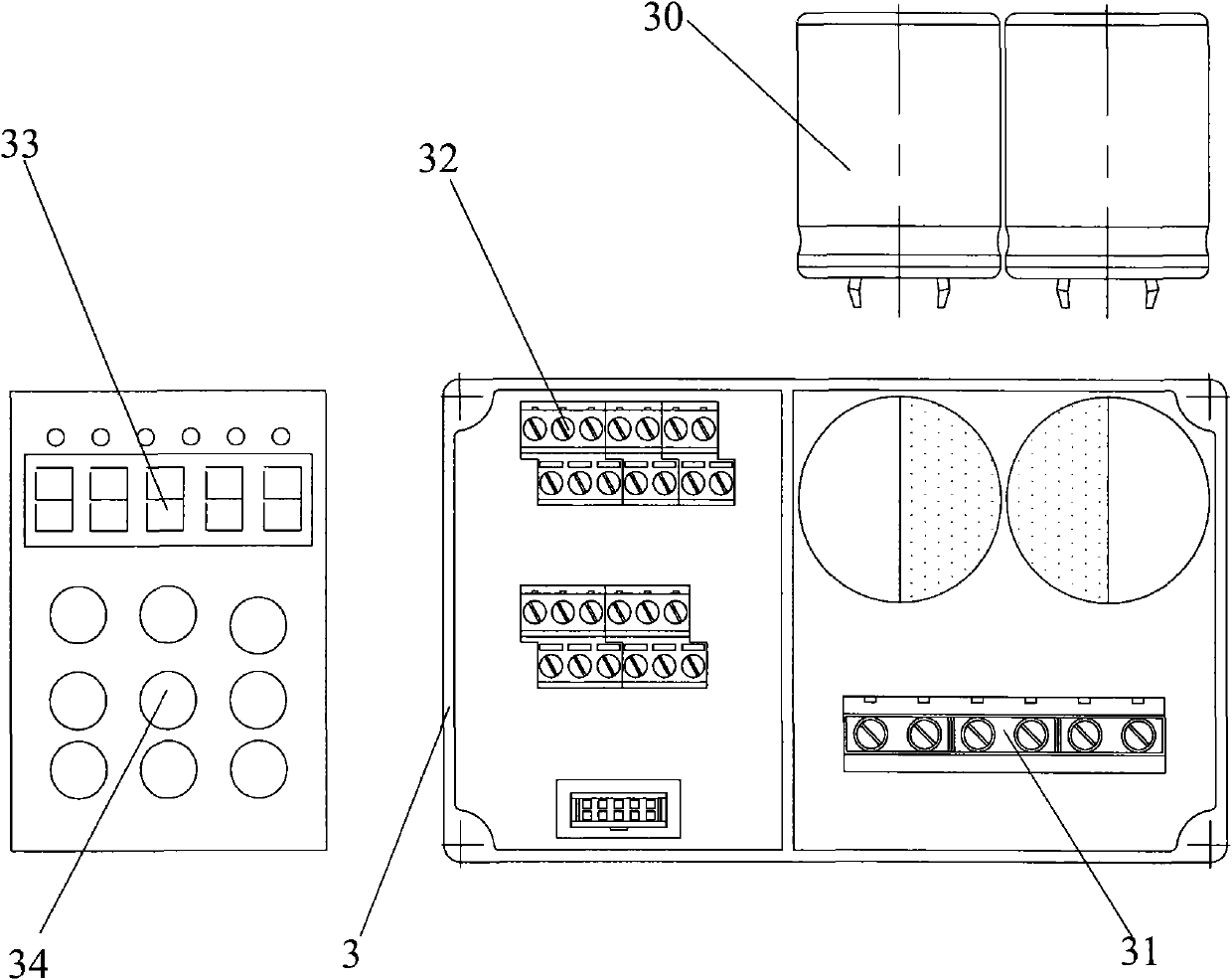

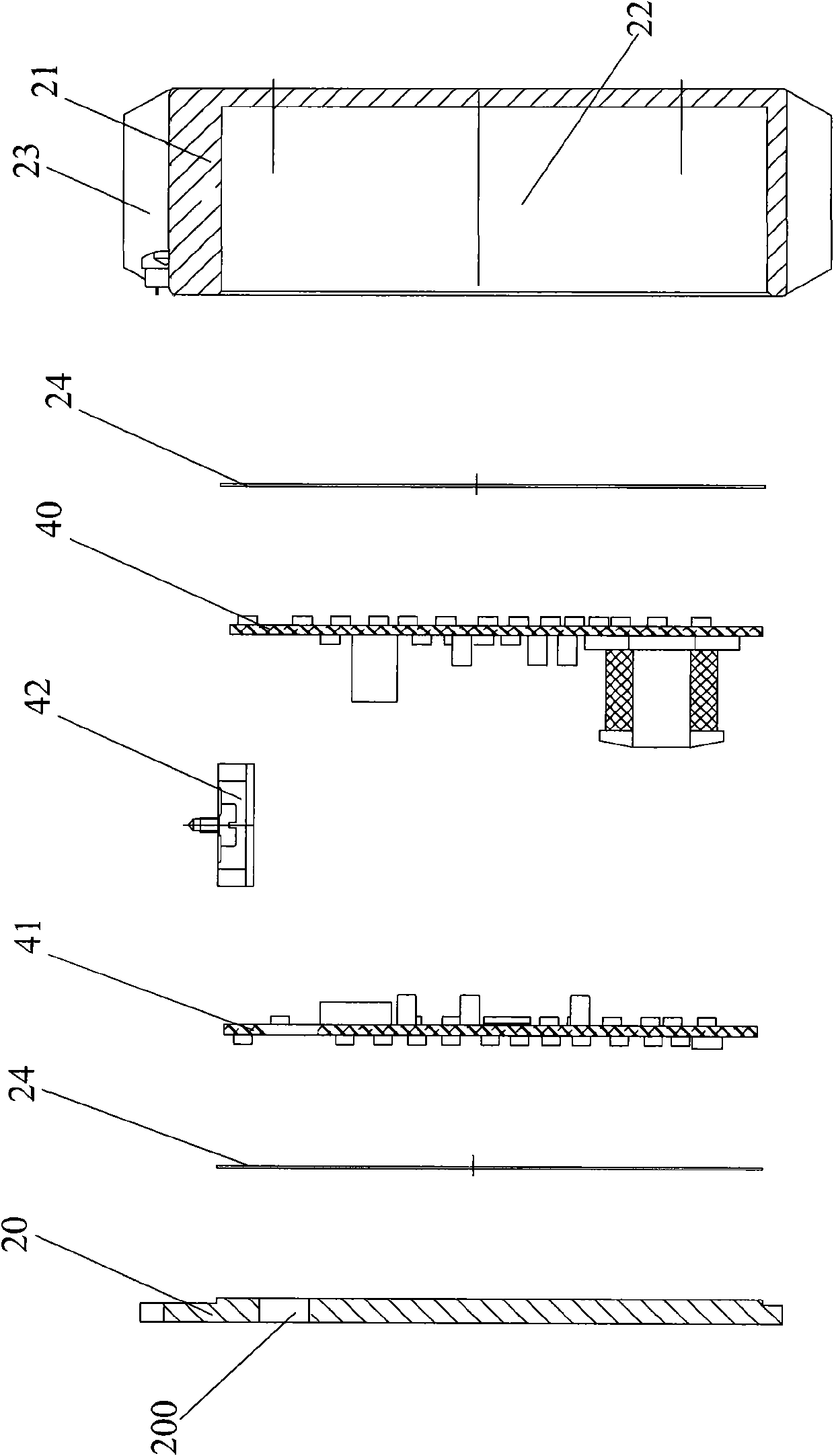

[0017] Such as figure 1 and figure 2 As shown, the variable frequency and variable speed motor of the present invention includes a motor body 1, a radiator 2, a junction box 3 and a frequency converter electrically connected to the motor body, the variable frequency variable speed motor is a combination of the frequency converter and the motor body 1, and the radiator 2 is set At the tail end cover of the motor body 1 , the junction box 3 is disposed on the motor body 1 , and the frequency converter includes a drive board 40 , a main control board 41 and a power element 42 electrically connected. The radiator 2 in the present invention includes a cover body 20 and an accommodating portion 21 with an open end, the cover body 20 is arranged at the opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com