Elevating mechanism for cutting machine head of five-axis steel tube intersecting line

A lifting mechanism, intersecting line technology, applied in the field of five-axis steel pipe intersecting line cutting machine, can solve the problems of difficult to cut complex steel pipe intersecting lines, unable to cut grooves, etc., to achieve stable and reliable mechanical action, high cutting efficiency, The effect of expanding the stroke range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

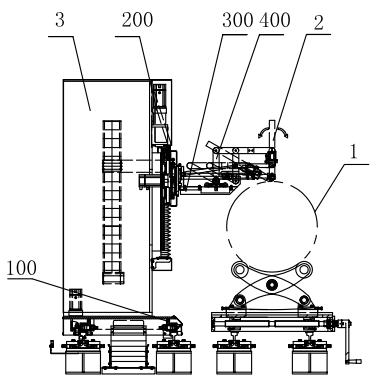

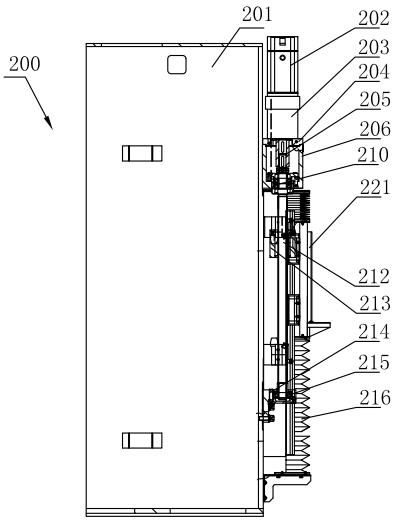

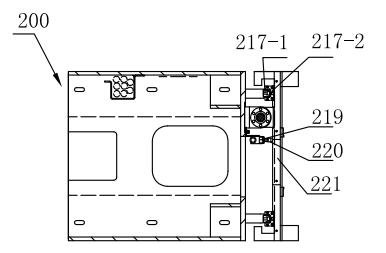

[0014] Such as figure 1 As shown, the five-axis steel pipe intersecting wire cutting machine of the present invention includes a spindle box located at one end of the cutting machine, the output end of the spindle box is connected to a rotary chuck, which clamps the end of the steel pipe 1 and provides the driving force for rotation; the base of the cutting machine There are two parallel tracks on the top, one track is located at the lower part of the pipe material to be processed, and several steel pipe support frames are set on this track for supporting the steel pipe 1; the cutting head moving assembly 3 is movably set on the other track On the top, it is connected with the power part and control part of the cutting machine through pipelines. The cutting head movement assembly 3 includes a cutting head longitudinal moving part 100, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com