Wall plastering and building solidifying material

A technology for walls and raw materials, applied in the field of building materials, can solve the problems of shrinkage cracking, pulverization, low strength, etc., and achieve the effects of low shrinkage rate, reduction of plastic shrinkage, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

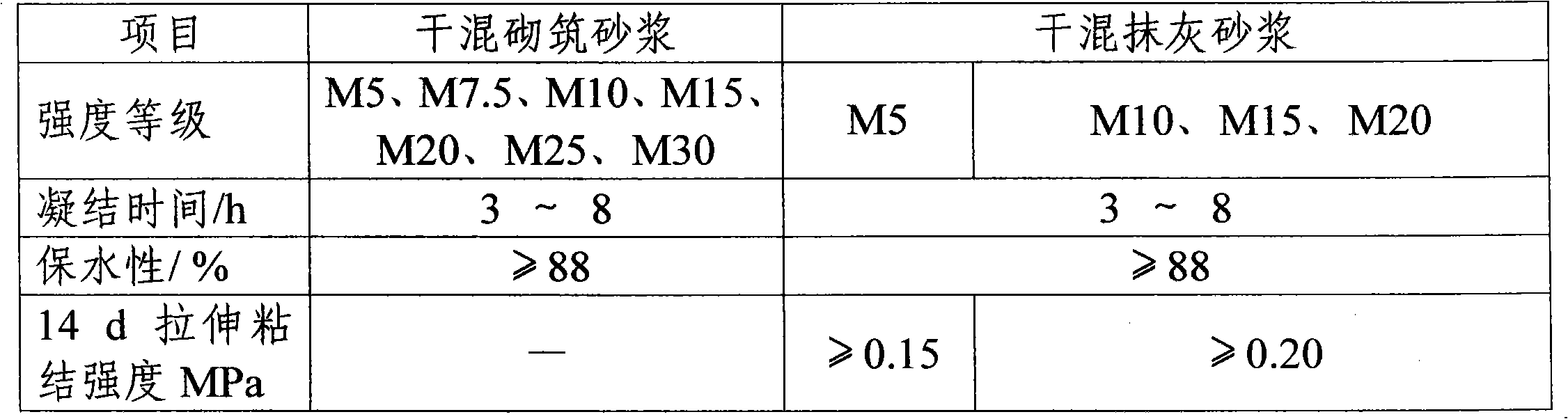

[0027] Wall plastering and masonry coagulation, its composition mass percentage ratio:

[0028] Cement 28%

[0029] Fly Ash 60%

[0031] Sodium dodecylbenzenesulfonate 0.15%

[0032] Methylcellulose 0.85%

[0033] Vinyl acetate-ethylene homopolymer 1%.

[0034] Mix the above materials evenly to obtain coagulated material, mix with sand and water according to the ratio of coagulated material: sand: water = 1: 3.0: 0.22, and stir in a mixer for 3 to 5 minutes to obtain M5 masonry mortar. Its performance is as follows:

[0035] Strength 6.8MPa

[0036] Setting time 6.2h

[0037] Water retention 92%.

Embodiment 2

[0039] Wall plastering and masonry coagulation, its composition and mass ratio:

[0040] Cement 25%

[0041] Fly Ash 43%

[0042] Mineral powder (S95) 20%

[0043] lime powder 10%

[0044] Sodium Lauryl Sulfate 0.10%

[0045] Carboxymethylcellulose 1%

[0046] Vinyl acetate homopolymer 0.9%.

[0047] Mix the above materials evenly to obtain coagulated material, mix with sand and water according to the ratio of coagulated material: sand: water = 1: 2.5: 0.23, and stir in a mixer for 3 to 5 minutes to obtain M5 plastering mortar. Its performance is as follows:

[0048] Strength 7.6MPa

[0049] Setting time 6.7h

[0050] Water retention 96%

[0051] 14d tensile bond strength 0.8MPa.

Embodiment 3

[0053] Wall plastering and masonry coagulation, its composition and mass ratio:

[0054] Cement 45%

[0055] Fly Ash 25%

[0056] Mineral powder (S95) 25%

[0057] Lime powder 2.7%

[0058] Sodium lauryl sulfate 0.06%

[0059] Hydroxypropyl Methyl Cellulose 1.2%

[0060] Vinyl acetate-ethylene homopolymer 1.04%.

[0061] Mix the above materials evenly to obtain coagulated material, mix with sand and water according to the ratio of coagulated material: sand: water = 1: 2.5: 0.25, and stir in a mixer for 3 to 5 minutes to obtain M20 plastering mortar. Its performance is as follows:

[0062] Strength 16.6MPa

[0063] Setting time 7.3h

[0064] Water retention 98%

[0065] 14d tensile bond strength 1.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com