Method for preparing potassium-sodium niobate textured ceramic and potassium-sodium niobate single crystal

A technology of potassium sodium niobate and ceramics, which is applied in the field of preparation of potassium sodium niobate textured ceramics and potassium sodium niobate single crystal, which can solve problems such as difficulties, precise control, and piezoelectric performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , Li 2 CO 3 and Bi 2 o 3 As a raw material, according to the chemical formula:

[0019] 0.996 (K 0.5 Na 0.5 )NbO 3 -0.004LiBiO 3

[0020] Carry out batching, wet mill with absolute ethanol as the medium for 12 hours, dry and keep warm at 880°C for 6 hours to pre-synthesize porcelain material; Compressed under pressure to φ18×2mm 2 Biscuit sample.

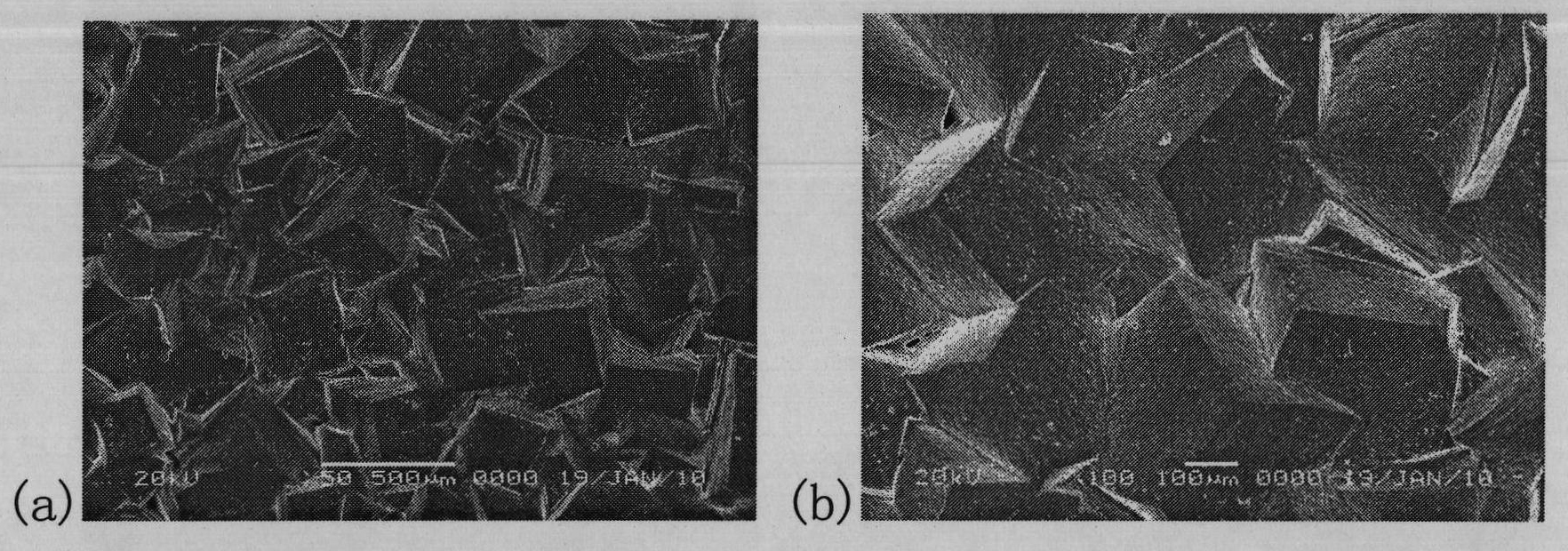

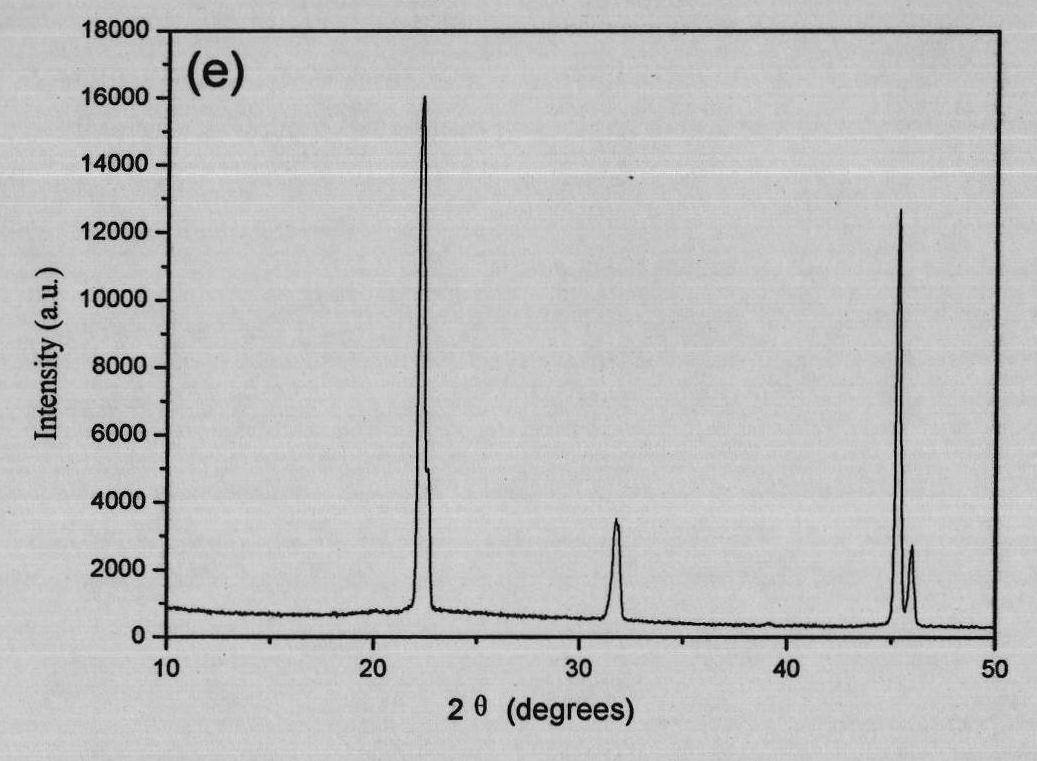

[0021] The green sample was placed horizontally in a high-temperature electric furnace, held at 500°C for 2 hours to debinding, and finally sintered at 1125°C for 3 hours to obtain sintered ceramics. Microstructural analysis shows that the ceramics have obvious directional growth characteristics, complete crystal form and clear texture. figure 1 and figure 2 Shown are the natural surface SEM photographs and cross-sectional XRD patterns of the samples prepared in Example 1, respectively.

Embodiment 2

[0023] Take Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , Li 2 CO 3 and Bi 2 o 3 As a raw material, according to the chemical formula:

[0024] 0.996 (K 0.5 Na 0.5 )NbO 3 -0.005LiBiO 3

[0025]Carry out batching, wet mill with absolute ethanol as the medium for 12 hours, dry and keep warm at 880°C for 6 hours to pre-synthesize porcelain material; Compressed under pressure to φ18×2mm 2 Biscuit sample.

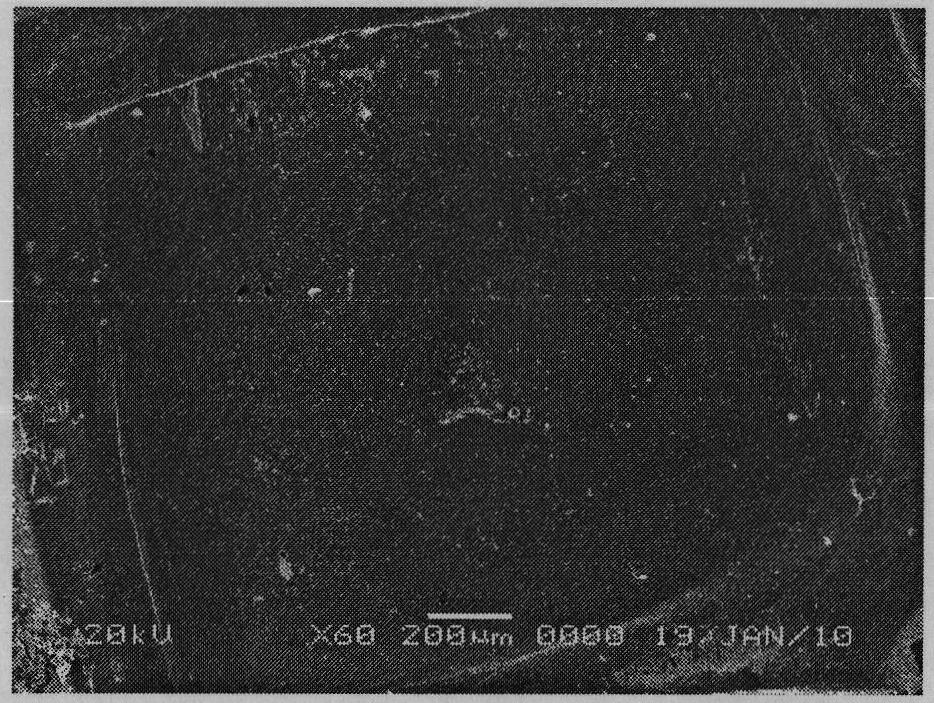

[0026] The green body sample was placed horizontally in a high-temperature electric furnace, held at 500°C for 2 hours to debinding, and finally sintered at 1125°C for 12 hours to obtain sintered ceramics. Microstructural analysis showed that larger single-crystal grains with a size of about 2 mm grew out of the ceramic. image 3 Shown is the SEM photo of the single crystal prepared in Example 2.

Embodiment 3

[0028] Take Na 2 CO 3 、K 2 CO 3 , Nb 2 o 5 , Li 2 CO 3 and Bi 2 o 3 As a raw material, according to the chemical formula:

[0029] 0.996 (K 0.5 Na 0.5 )NbO 3 -0.005LiBiO 3

[0030] Carry out batching, wet mill with absolute ethanol as the medium for 12 hours, dry and keep warm at 880°C for 6 hours to pre-synthesize porcelain material; Compressed under pressure to φ18×2mm 2 Biscuit sample.

[0031] The biscuit sample was placed horizontally in a high-temperature electric furnace, held at 500°C for 2 hours to remove the glue, and finally sintered at 1115°C for 10 hours to obtain a sintered ceramic. Microstructural analysis shows that the ceramics have significant directional growth characteristics, and the ceramics are dense and the single crystal particle size is about 1-2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com