Transparent conducting film and preparation method thereof, solar battery and flat panel display device

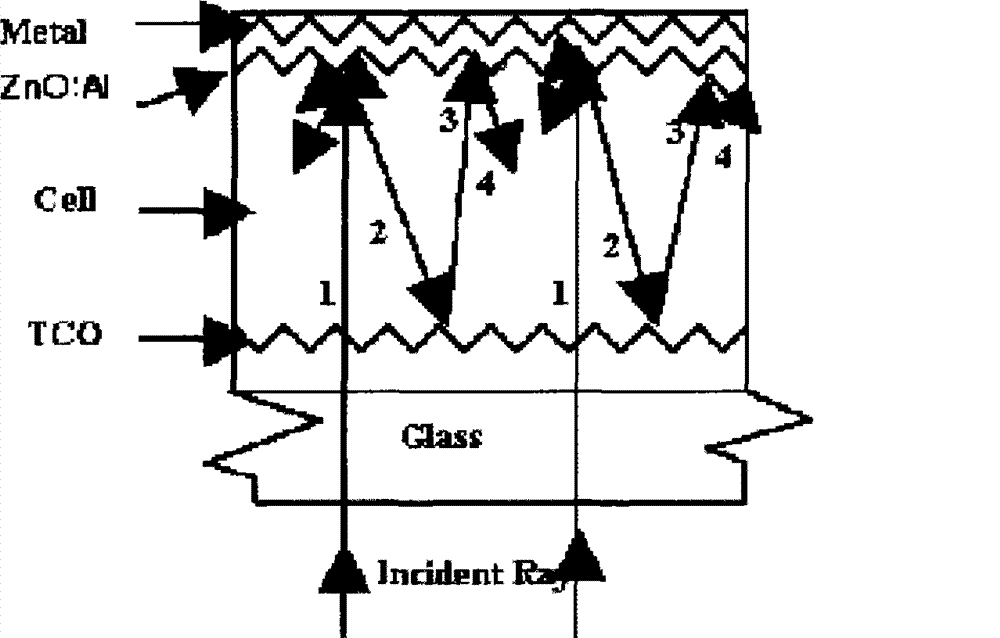

A technology of transparent conductive film and manufacturing method, applied in semiconductor/solid-state device manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of long process time, affecting film performance, and difficulty in maintaining stable grain orientation of zinc oxide film and other problems, to achieve uniform suede structure, improve photoelectric conversion efficiency, and good light absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Please refer to figure 2 , providing a substrate 10, the substrate 10 may be glass, such as common Corning 1737 glass. Of course, the substrate 10 may also be made of other materials, such as other materials applicable to solar cells or flat panel display panels. Here, only the substrate 10 is made of glass as an example for illustration.

[0049] Next, please refer to image 3 , forming a seed layer 12 containing zinc oxide on the substrate 10, wherein the process of forming the seed layer 12 may be magnetron sputtering.

[0050] In the magnetron sputtering method of this embodiment, AZO (aluminum oxide content is 0.2 to 2wt.%) is used as the target material, and the aluminum in AZO is used as the impurity material of the seed layer formed, and the seed layer formed is aluminum-doped Doped zinc oxide, aluminum is used to improve electrical conductivity.

[0051] Wherein, in the process of forming the seed layer by the magnetron sputtering method of the present emb...

Embodiment 2

[0062] In this example, the processes for forming the seed layer containing zinc oxide and the main layer containing zinc oxide are metal-organic chemical vapor deposition methods, and in the deposition process, diethyl zinc (DEZ) is used as the zinc source and water vapor is used as the oxygen source. By controlling the flow rate of diethyl zinc or process temperature, etc., the growth rate and grain size of the formed zinc oxide film can be controlled. In this embodiment, the growth rate and microstructure of the zinc oxide film are adjusted by adjusting the flow rate of diethyl zinc, and the process temperature is controlled at 130°C to 160°C, specifically about 155°C. In the zinc oxide film, the with B 2 h 6 Doping boron impurities as a dopant, B 2 h 6 The doping ratio with DEZ (flux doping ratio) is about 0.6.

[0063] Wherein, in the zinc seed layer deposition process, the flow rate of diethyl zinc is 5 sccm to 10 sccm, the water vapor flow rate is 6 sccm to 13 sccm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com