A kind of composite carbon counter electrode material and its preparation method and application

A technology of electrode material and composite carbon, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the photovoltaic performance is difficult to continue to improve, and the interface contact performance between carbon and perovskite deteriorates, so as to achieve improved photovoltaic performance and repeatable High performance and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of composite carbon counter electrode material of the present invention comprises the following steps:

[0030] A. Weigh each raw material according to the formula ratio, and obtain material a after mixing evenly for subsequent use;

[0031] B. Add a solvent that is 2 to 3.5 times the volume of material a to material a, grind at room temperature for 6 to 24 hours to obtain material b;

[0032] C. Evaporate the material b to remove the solvent to obtain the target compound carbon counter electrode material.

[0033] Described solvent is terpineol and / or dehydrated alcohol.

[0034] The evaporation described in step C is at a temperature of 40-70° C. through rotary evaporation or heating and stirring evaporation.

[0035] The application of the composite carbon counter electrode material in the present invention is the application of the composite carbon counter electrode material in preparing a composite carbon counter electrode film.

[0036] T...

Embodiment 1

[0039] A. Weigh graphite powder 4g and carbon black 1g and mix in the ball mill jar;

[0040] B. Add 12.5ml of terpineol and 20ml of absolute ethanol, grind it in a planetary ball mill for 24 hours and take it out;

[0041] C. After the grinding is completed, heat and stir at 40°C to evaporate and remove excess ethanol to obtain a carbon slurry without liquid metal addition;

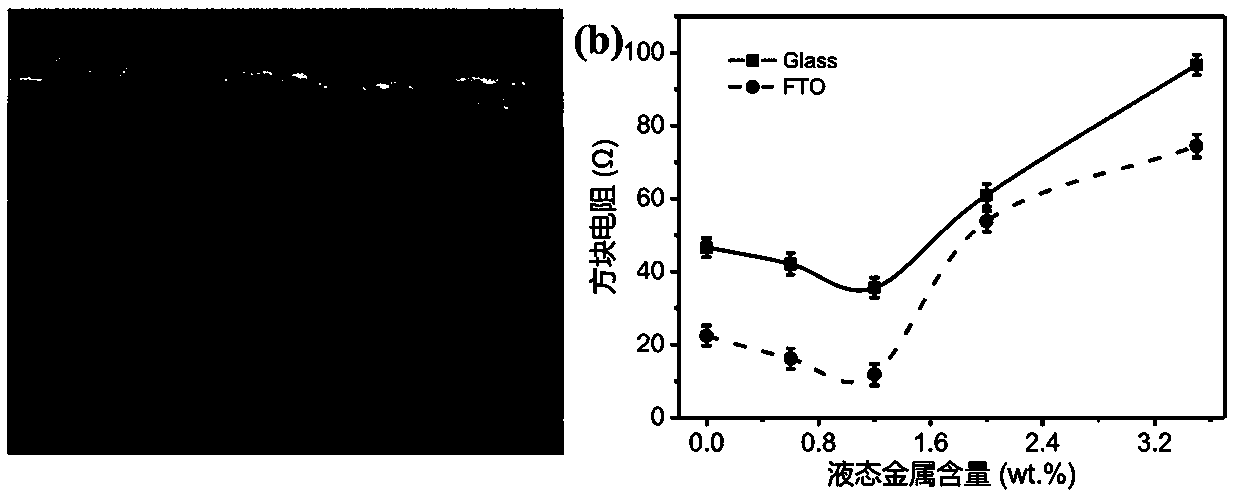

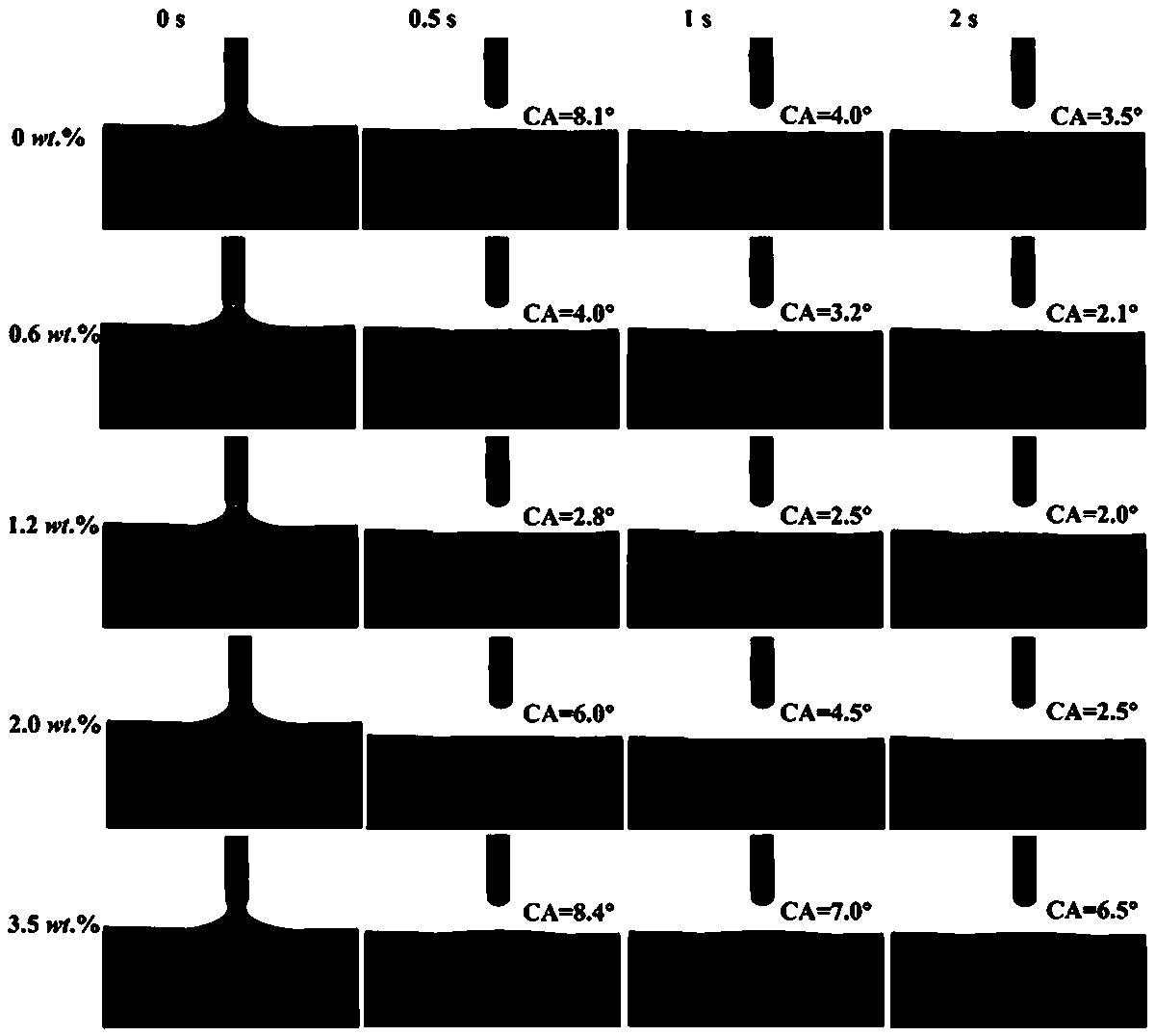

[0042] D. The prepared carbon paste was printed on the glass and the conductive glass substrate covered with FTO by screen printing technology, and then dried on a hot plate at 70°C, and then annealed at 400°C 40min.

Embodiment 2

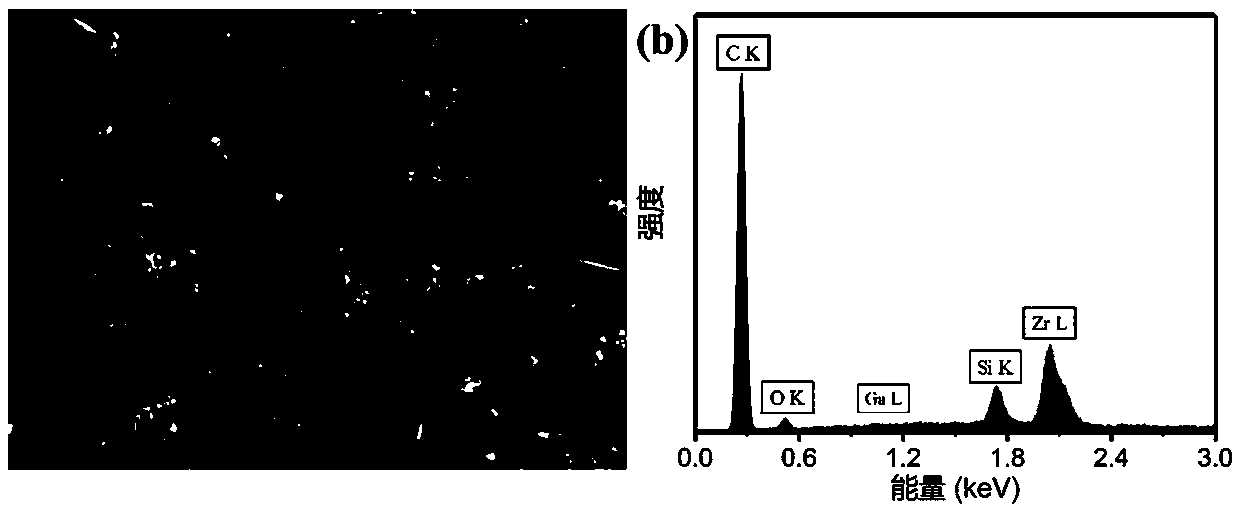

[0044] A. Weigh 4g of graphite powder and 1g of carbon black, then weigh 35mg of gallium-based liquid metal, and mix them together in a ball mill jar;

[0045] B. Add 12.5ml of terpineol and 20ml of absolute ethanol, grind it in a planetary ball mill for 24 hours and take it out;

[0046] C. After grinding, remove excess ethanol by rotary evaporation at 40°C to obtain a composite carbon slurry containing 0.6% liquid metal mass fraction;

[0047] D. The prepared carbon paste was printed on the glass and the conductive glass substrate covered with FTO by screen printing technology, and then dried on a hot plate at 70°C, and then annealed at 400°C 40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com