Cation water-based nano silicon dioxide and preparation method and application thereof

A technology of nano-silica and cations, which is applied in the treatment of dyed low-molecular organic compounds, dyed organosilicon compounds, and fibrous fillers. It can solve problems affecting the stability and uniformity of dispersions, and achieve high stability, Effect of improving surface properties and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Add 230 parts by weight of water in an open reactor at 5-40°C, then add 6 parts by weight of octadecyldimethylbenzyl ammonium chloride and 3 parts by weight of concentrated hydrochloric acid with a mass concentration of 37%, and stir 5 minutes to dissolve;

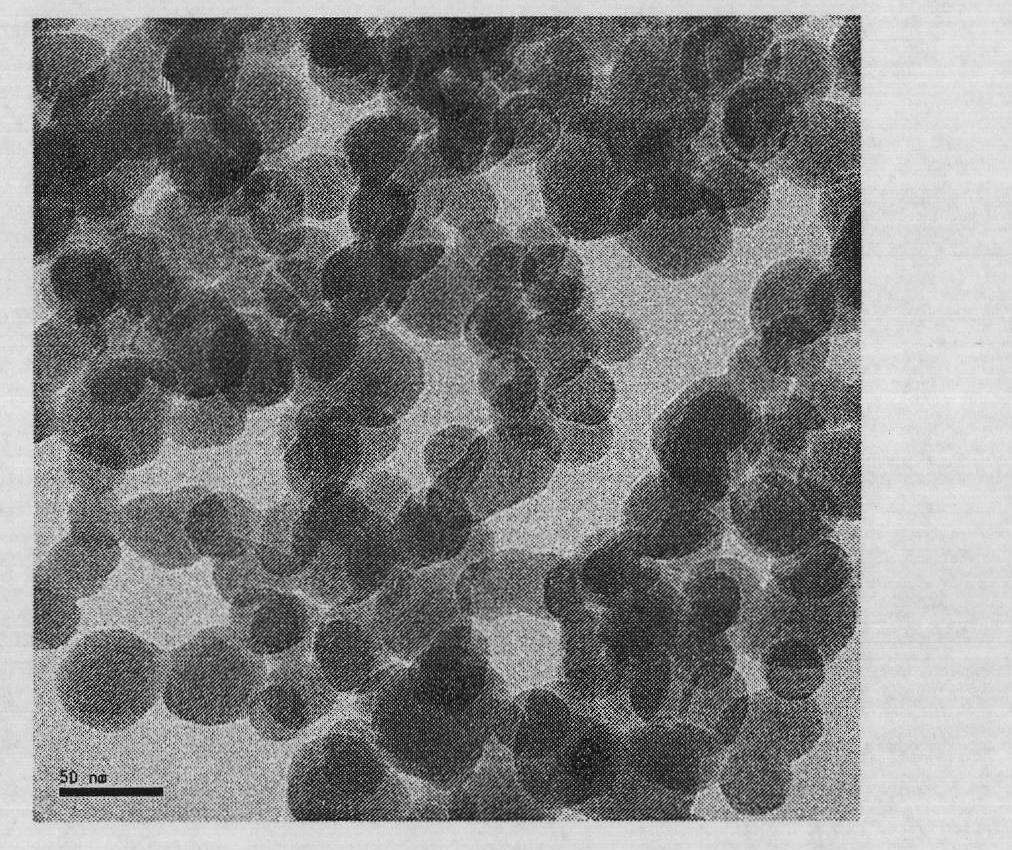

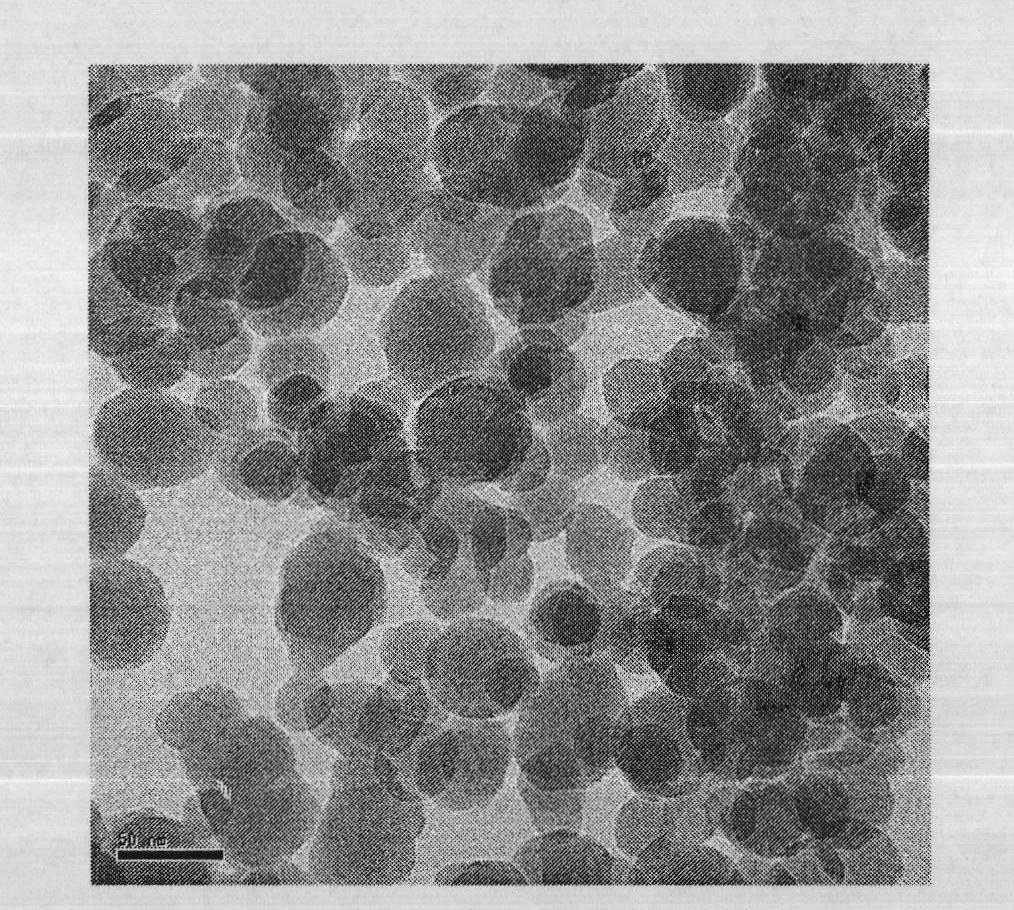

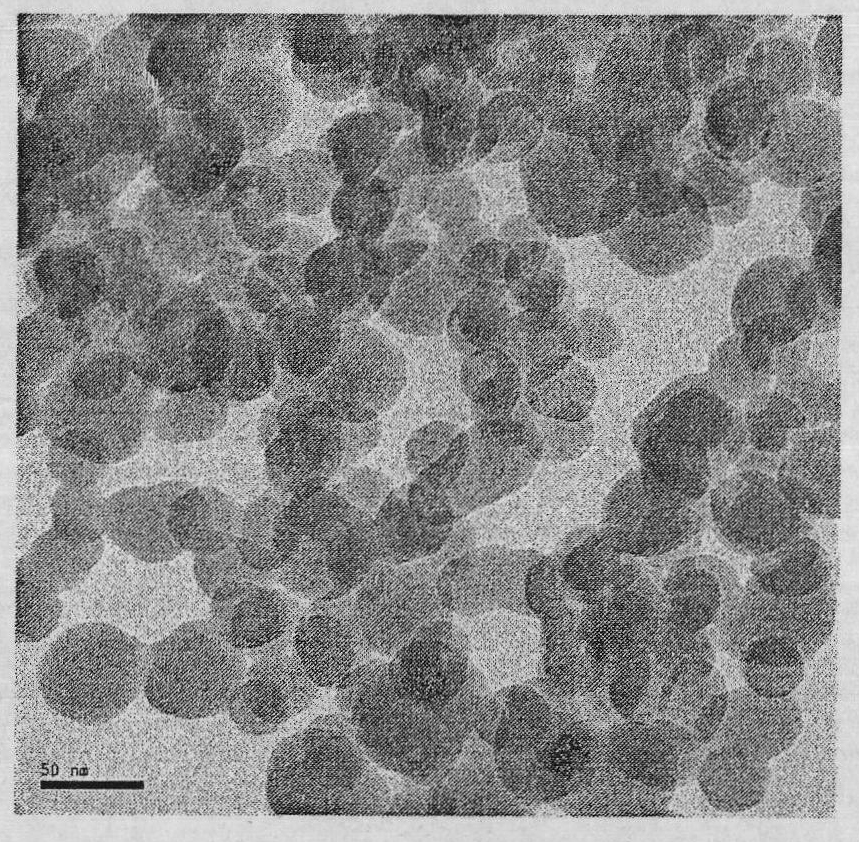

[0032] 2) Add 60 parts by weight of nano-silica micropowder with a particle size of 10-100 nm into the reactor, and stir at a high speed of 4000 r / min for 5 minutes to obtain a low-viscosity translucent solution;

[0033] 3) While stirring at high speed in step 2), add 6 parts by weight of aminosilane coupling agent dropwise into the reactor for 10 minutes;

[0034] 4) Adjust the pH value of the solution to 3-4 and continue to stir the solution for 10 minutes to obtain a translucent cationic water-based nano-silica (i.e. nano-silica dispersion), which can be placed at room temperature for more than 6 months without condensation glue.

[0035] The aminosilane coupling agent is 3-aminopropyltrimethoxysilane (or 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com